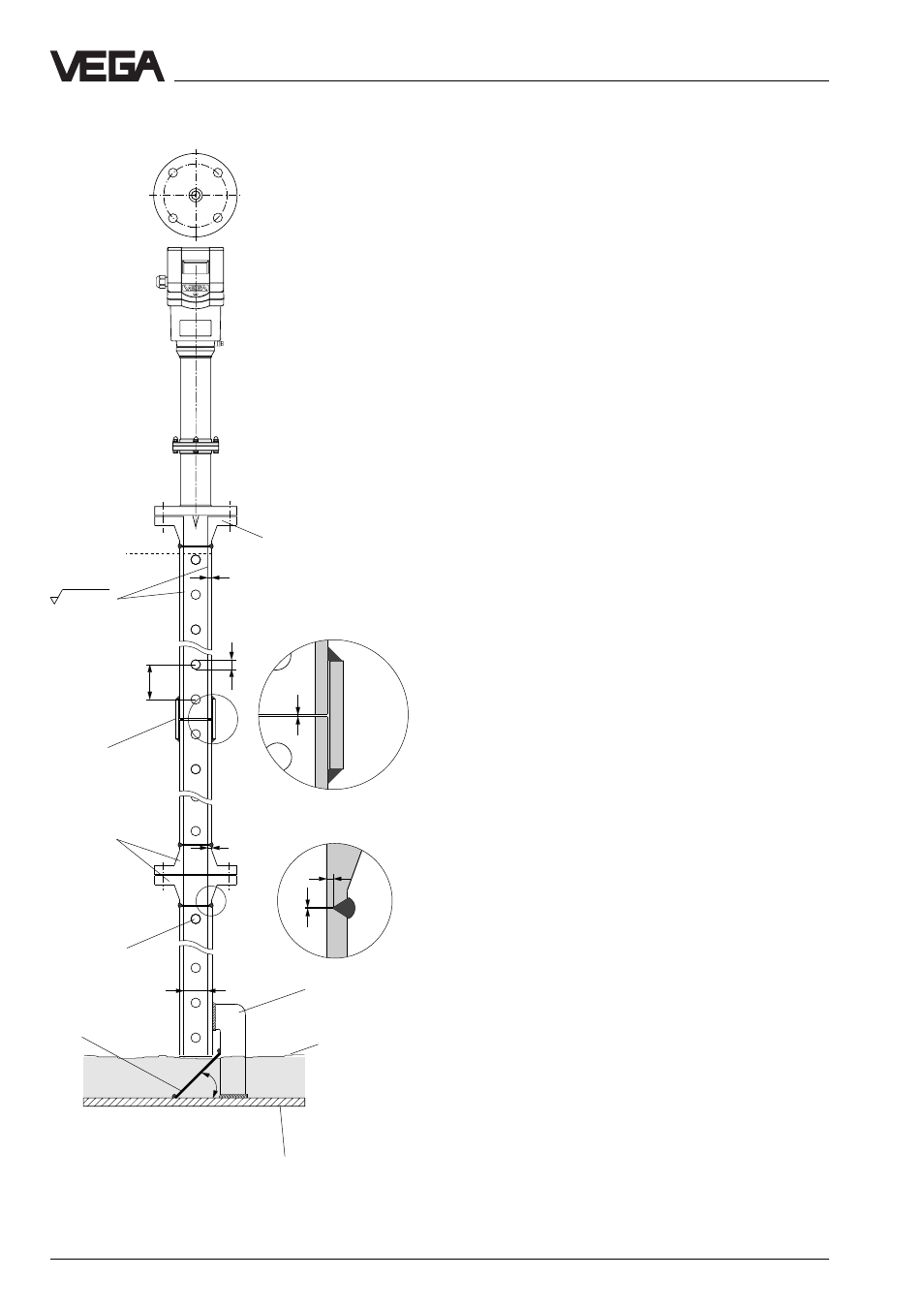

Construction instructions for standpipe, Mounting and installation – VEGA VEGAPULS 56V User Manual

Page 38

38

VEGAPULS 56V

0 %

~45

••

ø 51,2

0,0…0,4

1,5…2

2,9

0,0...0,4

150…500

5…15

2,9…6

100 %

Mounting and installation

Construction instructions for standpipe

Radar sensors for measurement on surge or

bypass pipes are used in flange sizes

DN!50, DN!80, DN!100 and DN!150.

On the left is the construction of a measuring

pipe (surge or bypass pipe) in the example

of a sensor with a DN!50 flange.

The radar sensor with a DN!50 flange is only

in conjunction with a measuring pipe a func-

tional system.

The measuring pipe must be smooth inside

(average roughness Rz!

≤!30). Use as mea-

suring pipe a stainless steel pipe without

joint. Extend the measuring pipe to the re-

quired length with welding neck flanges or

with connecting sleeves. Note that no shoul-

ders are caused in the pipe during welding.

Fasten the pipe and the flange before weld-

ing in alinement with the inner sides.

Do not just weld through the pipe wall.

Roughnesses or joints must be removed

carefully as otherwise strong false echoes

and build-up will be caused.

Flange DN 50

Welding neck flange

Connecting

sleeve

Welding neck

flanges

Welding of the connect-

ing sleeve

Welding of the welding

neck flange

Fastening of

measuring pipe

Vessel bottom

Deflector

Min. product level

to be measured

(0!%)

Rz

≤ 30

Burr the

holes