Carrier installation, Carrier inst – Spicer Drive Axles Service Manual Wheel Reduction Drive Axles (EA-50) User Manual

Page 32

30

CARRIER INST

CARRIER INST

CARRIER INST

CARRIER INST

CARRIER INSTALLA

ALLA

ALLA

ALLA

ALLATION

TION

TION

TION

TION

AIR PRESSURE METHOD

1. Install the right-side axle shaft through the

clutch collar and into the differential side gear of

the carrier assembly. The axle shaft is used to

align splines of the the differential case half and

clutch collar.

2. Rotate right-side axle shaft until splines of clutch

collar and the differential case half are aligned.

CA

CA

CA

CA

CAUTION: Do no

UTION: Do no

UTION: Do no

UTION: Do no

UTION: Do not use hands t

t use hands t

t use hands t

t use hands t

t use hands to position shift

o position shift

o position shift

o position shift

o position shift

collar while air pr

collar while air pr

collar while air pr

collar while air pr

collar while air preeeeessur

ssur

ssur

ssur

ssure is being applied t

e is being applied t

e is being applied t

e is being applied t

e is being applied to shift

o shift

o shift

o shift

o shift

cylinder

cylinder

cylinder

cylinder

cylinder, injury could r

, injury could r

, injury could r

, injury could r

, injury could reeeeesult.

sult.

sult.

sult.

sult.

3. Connect auxiliary air supply to shift cylinder.

4. Apply and hold air pressure to the shift cylinder.

Applying air will move the shift collar inward

and engage the splines with the differential case

splines locking the assembly.

5. To ensure the clutch collar and differential case

splines have engaged completely, rotate right-side axle

shaft. When fully engaged remove shaft from the

carrier assembly.

IMPOR

IMPOR

IMPOR

IMPOR

IMPORT

T

T

T

TANT

ANT

ANT

ANT

ANT: Hold air pr

: Hold air pr

: Hold air pr

: Hold air pr

: Hold air preeeeessur

ssur

ssur

ssur

ssure on lock

e on lock

e on lock

e on lock

e on locked carrier

ed carrier

ed carrier

ed carrier

ed carrier

aaaaassembl

ssembl

ssembl

ssembl

ssembly until it ha

y until it ha

y until it ha

y until it ha

y until it has been comple

s been comple

s been comple

s been comple

s been completttttel

el

el

el

ely inst

y inst

y inst

y inst

y installed int

alled int

alled int

alled int

alled into

oo

oo

axle housing.

axle housing.

axle housing.

axle housing.

axle housing.

6. Install carrier assembly into axle housing and fasten

using normal installation procedures.

7. Remove auxiliary air supply from shift assembly and

connect the vehicle air line to shift cylinder.

8. Install axle shafts into housing. Use procedures 2 and

3 from the "Inst

"Inst

"Inst

"Inst

"Install Axle Shaft

all Axle Shaft

all Axle Shaft

all Axle Shaft

all Axle Shafts Aft

s Aft

s Aft

s Aft

s After T

er T

er T

er T

er To

oo

oowing"

wing"

wing"

wing"

wing"

section.

9. Remove jack stands from vehicle and lower to shop

floor.

MANUAL ENGAGING METHOD

1. Align the splines of the clutch collar and the

differential case by hand.

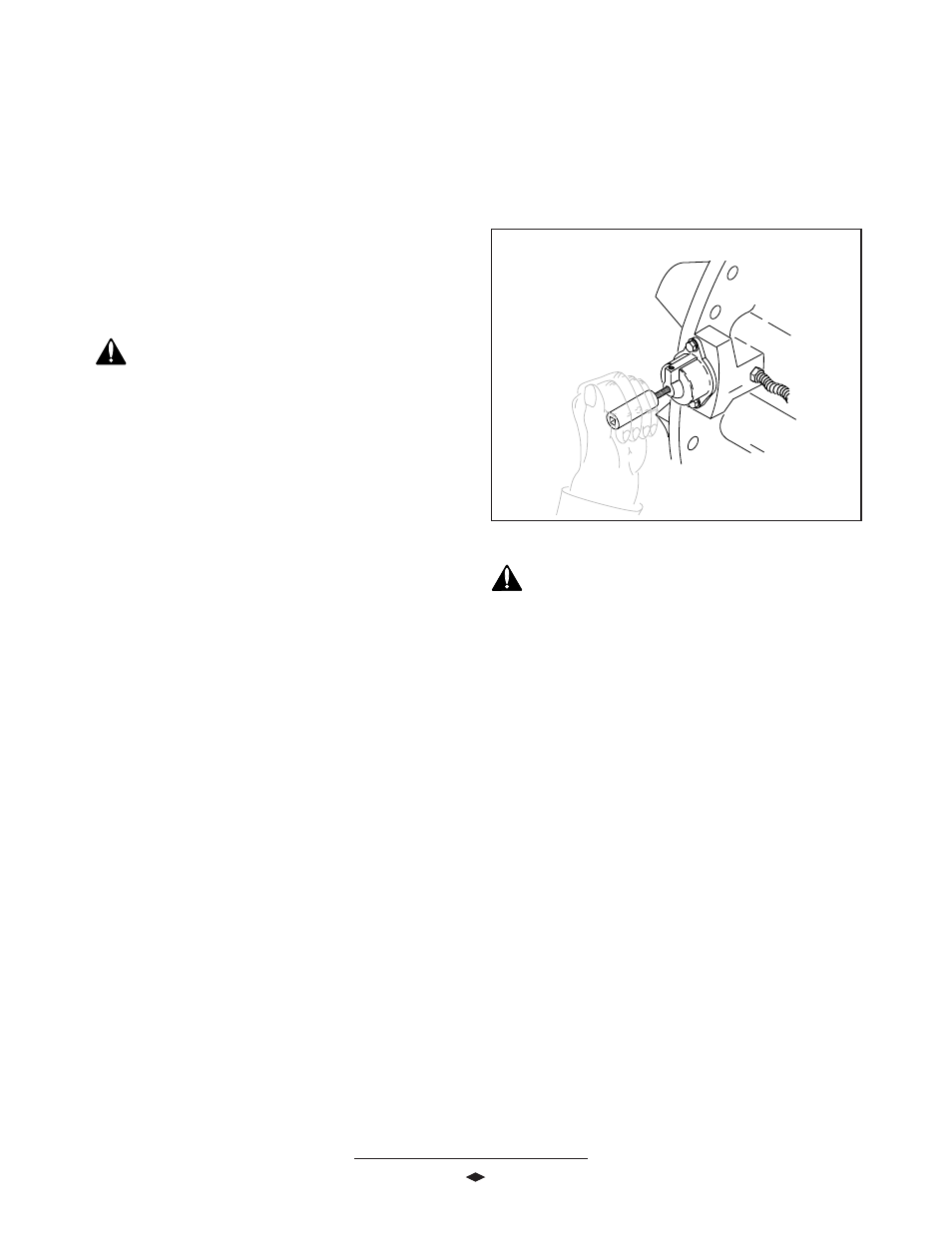

2. Install a M12 X 1.50 bolt into the shift cylinder

air-port to manually engage the lock.

IMPOR

IMPOR

IMPOR

IMPOR

IMPORT

T

T

T

TANT

ANT

ANT

ANT

ANT: Hand tight

: Hand tight

: Hand tight

: Hand tight

: Hand tighten M1

en M1

en M1

en M1

en M12 X 1.5

2 X 1.5

2 X 1.5

2 X 1.5

2 X 1.50 bolt with a

0 bolt with a

0 bolt with a

0 bolt with a

0 bolt with a

sock

sock

sock

sock

sockeeeeet. See F

t. See F

t. See F

t. See F

t. See Figur

igur

igur

igur

igure 1

e 1

e 1

e 1

e 17

7

7

7

7.....

CA

CA

CA

CA

CAUTION: If a high r

UTION: If a high r

UTION: If a high r

UTION: If a high r

UTION: If a high reeeeesist

sist

sist

sist

sistance t

ance t

ance t

ance t

ance to turn is felt

o turn is felt

o turn is felt

o turn is felt

o turn is felt

befor

befor

befor

befor

before full engagement of lock, st

e full engagement of lock, st

e full engagement of lock, st

e full engagement of lock, st

e full engagement of lock, stop turning the bolt.

op turning the bolt.

op turning the bolt.

op turning the bolt.

op turning the bolt.

Ov

Ov

Ov

Ov

Over

er

er

er

er-t

-t

-t

-t

-tor

or

or

or

orquing ma

quing ma

quing ma

quing ma

quing may cause damage t

y cause damage t

y cause damage t

y cause damage t

y cause damage to the shift unit.

o the shift unit.

o the shift unit.

o the shift unit.

o the shift unit.

R

RR

R

Realign spline

ealign spline

ealign spline

ealign spline

ealign splines and contin

s and contin

s and contin

s and contin

s and continue t

ue t

ue t

ue t

ue to tight

o tight

o tight

o tight

o tighten.

en.

en.

en.

en.

3. To ensure lock is fully engaged, rotate the drive

pinion.

4. Install carrier assembly into axle housing and fasten

using normal procedures.

5. Remove manual engaging bolt from shift cylinder,

replace with air shift cylinder plug and torque

20-30 Lb-Ft (27-41 N-m).

6. Connect the vehicle air line to the shift cylinder

assembly.

7. Install axle shafts into the axle housing. Use

procedures 2 and 3 from the "Inst

Inst

Inst

Inst

Install Axle Shaft

all Axle Shaft

all Axle Shaft

all Axle Shaft

all Axle Shaftsssss

Aft

Aft

Aft

Aft

After T

er T

er T

er T

er To

oo

oowing

wing

wing

wing

wing" section, page 26.

8. Remove jack stands from under vehicle and

lower to shop floor.

Carrier inst

Carrier inst

Carrier inst

Carrier inst

Carrier installation complet

allation complet

allation complet

allation complet

allation completeeeee

HAND TIGHTEN M12 X 1.50 BOLT

USING SOCKET

FFFFFigur

igur

igur

igur

igure 1

e 1

e 1

e 1

e 17

7

7

7

7