Pinion assembl – Spicer Drive Axles Service Manual Wheel Reduction Drive Axles (EA-50) User Manual

Page 18

16

PINION ASSEMBL

PINION ASSEMBL

PINION ASSEMBL

PINION ASSEMBL

PINION ASSEMBLY

Y

Y

Y

Y

NO

NO

NO

NO

NOTE: When t

TE: When t

TE: When t

TE: When t

TE: When tor

or

or

or

orque t

que t

que t

que t

que to r

o r

o r

o r

o ro

oo

ootttttaaaaattttte r

e r

e r

e r

e reading doe

eading doe

eading doe

eading doe

eading does no

s no

s no

s no

s not fall

t fall

t fall

t fall

t fall

within allo

within allo

within allo

within allo

within allow

w

w

w

wable limit

able limit

able limit

able limit

able limits, bearing pr

s, bearing pr

s, bearing pr

s, bearing pr

s, bearing preload can be

eload can be

eload can be

eload can be

eload can be

incr

incr

incr

incr

increa

ea

ea

ea

eased b

sed b

sed b

sed b

sed by using a thinner spacer or decr

y using a thinner spacer or decr

y using a thinner spacer or decr

y using a thinner spacer or decr

y using a thinner spacer or decrea

ea

ea

ea

eased b

sed b

sed b

sed b

sed byyyyy

using a thick

using a thick

using a thick

using a thick

using a thicker spacer

er spacer

er spacer

er spacer

er spacer. .00

. .00

. .00

. .00

. .001 in. (.0

1 in. (.0

1 in. (.0

1 in. (.0

1 in. (.02

2

2

2

25 mm) change in

5 mm) change in

5 mm) change in

5 mm) change in

5 mm) change in

pr

pr

pr

pr

preload spacer thickne

eload spacer thickne

eload spacer thickne

eload spacer thickne

eload spacer thickness, change

ss, change

ss, change

ss, change

ss, changes scale r

s scale r

s scale r

s scale r

s scale reading b

eading b

eading b

eading b

eading byyyyy

appr

appr

appr

appr

appro

oo

ooxima

xima

xima

xima

ximatttttel

el

el

el

ely 1

y 1

y 1

y 1

y 10 lbs, .00

0 lbs, .00

0 lbs, .00

0 lbs, .00

0 lbs, .001 in. change in pr

1 in. change in pr

1 in. change in pr

1 in. change in pr

1 in. change in preload

eload

eload

eload

eload

spacer will change t

spacer will change t

spacer will change t

spacer will change t

spacer will change tor

or

or

or

orque t

que t

que t

que t

que to r

o r

o r

o r

o ro

oo

ootttttaaaaattttte b

e b

e b

e b

e by appr

y appr

y appr

y appr

y appro

oo

ooxima

xima

xima

xima

ximatttttel

el

el

el

elyyyyy

3

3

3

3

30 Lb- in. This is onl

0 Lb- in. This is onl

0 Lb- in. This is onl

0 Lb- in. This is onl

0 Lb- in. This is only a guide, individual carrier

y a guide, individual carrier

y a guide, individual carrier

y a guide, individual carrier

y a guide, individual carriers ma

s ma

s ma

s ma

s mayyyyy

vvvvvary slightl

ary slightl

ary slightl

ary slightl

ary slightlyyyyy.....

The pinion bearing spacers are available in the following

thicknesses. Measure spacer with micrometers before

assembly to ensure correct thickness.

Inche

Inche

Inche

Inche

Inchesssss

MM

MM

MM

MM

MM

.893

22.982

.894

22.708

.895

22.733

1

1

1

1

12.

2.

2.

2.

2. Me

Me

Me

Me

Method B:

thod B:

thod B:

thod B:

thod B: To measure torque to rotate with the

torque wrench, assemble pinion cage into the carrier

housing and install two mounting bolts to anchor

the unit.

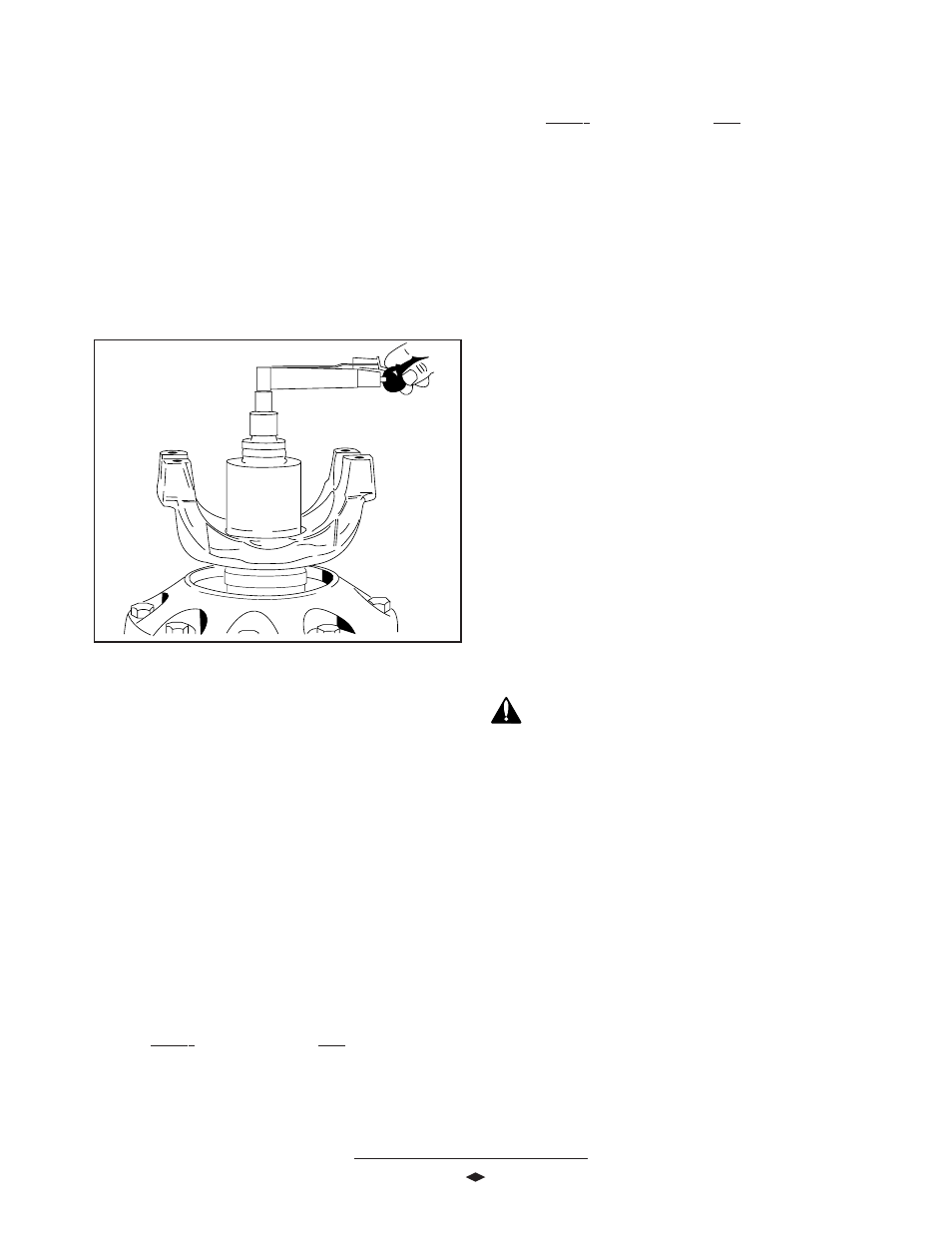

Rotate pinion with the torque wrench. See F

See F

See F

See F

See Figur

igur

igur

igur

igure 8

e 8

e 8

e 8

e 8.

Torque measurement will be taken during fourth revolu-

tion and must be between 10-40 Lb-in (1.1-4.5 N-m)

without pinion seal.

Inche

Inche

Inche

Inche

Inchesssss

MM

MM

MM

MM

MM

.896

22.758

.897

22.784

.898

22.809

.899

22.835

.900

22.860

.901

22.885

.902

22.911

.903

22.936

.904

22.962

.905

22.987

.906

23.012

.907

23.038

.908

23.063

.909

23.089

.910

23.114

.911

23.139

.916

23.266

NO

NO

NO

NO

NOTE: Closer adjustment can be made b

TE: Closer adjustment can be made b

TE: Closer adjustment can be made b

TE: Closer adjustment can be made b

TE: Closer adjustment can be made by sanding

y sanding

y sanding

y sanding

y sanding

ne

ne

ne

ne

next thick

xt thick

xt thick

xt thick

xt thicker spacer t

er spacer t

er spacer t

er spacer t

er spacer to de

o de

o de

o de

o desir

sir

sir

sir

sired thickne

ed thickne

ed thickne

ed thickne

ed thickness using emery

ss using emery

ss using emery

ss using emery

ss using emery

clo

clo

clo

clo

cloth on a fla

th on a fla

th on a fla

th on a fla

th on a flat sur

t sur

t sur

t sur

t surface. Sur

face. Sur

face. Sur

face. Sur

face. Surface

face

face

face

faces m

s m

s m

s m

s must be par

ust be par

ust be par

ust be par

ust be parallel t

allel t

allel t

allel t

allel to

oo

oo

each o

each o

each o

each o

each other and squar

ther and squar

ther and squar

ther and squar

ther and square t

e t

e t

e t

e to bor

o bor

o bor

o bor

o bore diame

e diame

e diame

e diame

e diamettttter

er

er

er

er.....

CA

CA

CA

CA

CAUTION: W

UTION: W

UTION: W

UTION: W

UTION: Waaaaash spacer thor

sh spacer thor

sh spacer thor

sh spacer thor

sh spacer thoroughl

oughl

oughl

oughl

oughly of emery

y of emery

y of emery

y of emery

y of emery

cut

cut

cut

cut

cuttings befor

tings befor

tings befor

tings befor

tings before inst

e inst

e inst

e inst

e installing on pinion.

alling on pinion.

alling on pinion.

alling on pinion.

alling on pinion.

1

1

1

1

14.

4.

4.

4.

4. After proper torque to rotate is achieved remove

end yoke.

1

1

1

1

15.

5.

5.

5.

5. Clean and dry threads on pinion.

1

1

1

1

16.

6.

6.

6.

6. Install pinion oil seal with R

RR

R

Recommended Service

ecommended Service

ecommended Service

ecommended Service

ecommended Service

T

T

T

T

Tool

ool

ool

ool

ool. See page 32.

1

1

1

1

17

7

7

7

7..... Install end yoke using yoke installer service tool

DST1007. See F

See F

See F

See F

See Figur

igur

igur

igur

igure 6.

e 6.

e 6.

e 6.

e 6.

1

1

1

1

18.

8.

8.

8.

8. Coat threads with Loctite #680 adhesive

compound.

FFFFFigur

igur

igur

igur

igure 8

e 8

e 8

e 8

e 8

(Continued on Ne

(Continued on Ne

(Continued on Ne

(Continued on Ne

(Continued on Next P

xt P

xt P

xt P

xt Page)

age)

age)

age)

age)