Installation of carrier into axle housing, Inst – Spicer Drive Axles Service Manual Wheel Reduction Drive Axles (EA-50) User Manual

Page 24

22

1.

1.

1.

1.

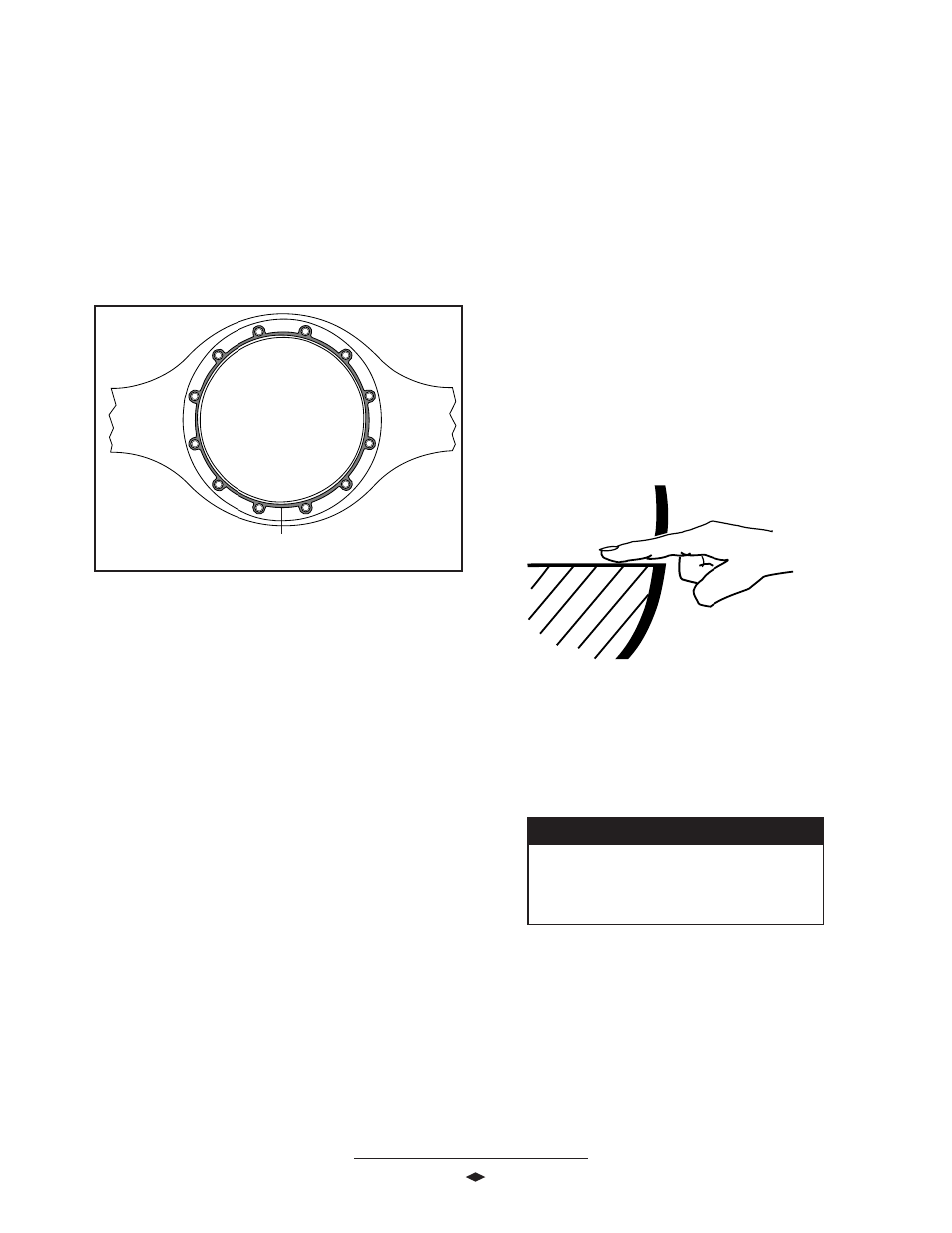

1. Thoroughly clean the inside of the carrier housing

and inspect the housing mounting surface for nicks

and general cleanliness. Stone the surface if

necessary to remove burrs or nicks. Bolt holes must

also be checked, to see that they are free of

contaminants.

INST

INST

INST

INST

INSTALLA

ALLA

ALLA

ALLA

ALLATION OF DIFFERENTIAL

TION OF DIFFERENTIAL

TION OF DIFFERENTIAL

TION OF DIFFERENTIAL

TION OF DIFFERENTIAL

CARRIER INTO AXLE HOUSING

CARRIER INTO AXLE HOUSING

CARRIER INTO AXLE HOUSING

CARRIER INTO AXLE HOUSING

CARRIER INTO AXLE HOUSING

FFFFFigur

igur

igur

igur

igure 1

e 1

e 1

e 1

e 11

1

1

1

1

Loctit

Loctit

Loctit

Loctit

Loctite 5

e 5

e 5

e 5

e 51

1

1

1

18

8

8

8

8

Ga

Ga

Ga

Ga

Gask

sk

sk

sk

sket Eliminat

et Eliminat

et Eliminat

et Eliminat

et Eliminator

or

or

or

or

2.

2.

2.

2.

2. Apply an .125 inch (3.175 mm) diameter bead of

Loctite 518 gasket eliminator onto the axle housing

mounting flange and around each bolt hole. See

See

See

See

See

FFFFFigur

igur

igur

igur

igure 1

e 1

e 1

e 1

e 11.

1.

1.

1.

1.

3.

3.

3.

3.

3. Thread two studs into the axle housing 180

0

apart.

This will eliminate rotation of the carrier assembly

after it makes contact with the gasket material.....

4.

4.

4.

4.

4. Install the carrier assembly into the axle housing.

If reinstalling used bolts, clean the mounting bolts,

and coat with Loctite #277, and install. Tighten

bolts evenly in cross pattern. Torque bolts

240-260 Lb-Ft (325-352 N-m).

5.

5.

5.

5.

5. Allow one hour cure time for gasket material before

adding hypoid gear lubricant.

6.

6.

6.

6.

6. Remove the old axle flange gasket and clean mating

surfaces of the hub and axle flange.

7

7

7

7

7.....

Install the new axle flange gasket.

8.

8.

8.

8.

8. Install the axle shafts to proper location.

Torque the axle flange nuts to vehicle manufacturers

specifications.

9.

9.

9.

9.

9. Clean drain plug and install. Torque drain plug to

35-45 Lb-Ft (47-61 N-m) Fill unit to proper

level with hypoid gear lubricant.

1

1

1

1

10.

0.

0.

0.

0. Install fill plug and torque to 35-45 Lb-Ft

(47-61 N-m).

NOTE : Lubricant close enough to bottom of fill hole to be seen

or touched is not sufficient. Lubricant must be level with the fill

hole.

S

SS

SS 2

2

2

2

23

3

3

3

30-S/SL

0-S/SL

0-S/SL

0-S/SL

0-S/SL

4

4

4

4

48.8

8.8

8.8

8.8

8.8

2

2

2

2

23.1

3.1

3.1

3.1

3.1

S2

S2

S2

S2

S26

6

6

6

60-SB

0-SB

0-SB

0-SB

0-SB

**

**

**

**

**

5

5

5

5

52.9

2.9

2.9

2.9

2.9

2

2

2

2

25.0

5.0

5.0

5.0

5.0

S2

S2

S2

S2

S26

6

6

6

60-SB

0-SB

0-SB

0-SB

0-SB

***

***

***

***

***

5

5

5

5

55.2

5.2

5.2

5.2

5.2

2

2

2

2

26.1

6.1

6.1

6.1

6.1

Model

Model

Model

Model

Model

Pint

Pint

Pint

Pint

Pintsssss

Lit

Lit

Lit

Lit

Liter

er

er

er

ersssss

CAP

CAP

CAP

CAP

CAPA

A

A

A

ACITIES (Appr

CITIES (Appr

CITIES (Appr

CITIES (Appr

CITIES (Appro

oo

ooxima

xima

xima

xima

ximattttte*):

e*):

e*):

e*):

e*):

* Lube capacity will vary depending upon the housing angle

in each vehicle. Capacities given above are for an angle of

4°. Fill to the lower edge of the fill hole in the axle housing

as shown above.

** Capacity for fabricated housing

*** Capacity for cast housing