Carrier removal (diff. lock), Carrier remov, Carrier remov carrier removal al al al al – Spicer Drive Axles Service Manual Wheel Reduction Drive Axles (EA-50) User Manual

Page 29

27

CARRIER REMOV

CARRIER REMOV

CARRIER REMOV

CARRIER REMOV

CARRIER REMOVAL

AL

AL

AL

AL

NO

NO

NO

NO

NOTE: Contin

TE: Contin

TE: Contin

TE: Contin

TE: Continue t

ue t

ue t

ue t

ue to k

o k

o k

o k

o keep differ

eep differ

eep differ

eep differ

eep differential lock engaged

ential lock engaged

ential lock engaged

ential lock engaged

ential lock engaged

(lock

(lock

(lock

(lock

(locked) with air pr

ed) with air pr

ed) with air pr

ed) with air pr

ed) with air preeeeessur

ssur

ssur

ssur

ssure until carrier ha

e until carrier ha

e until carrier ha

e until carrier ha

e until carrier has been

s been

s been

s been

s been

comple

comple

comple

comple

completttttel

el

el

el

ely r

y r

y r

y r

y remo

emo

emo

emo

emovvvvved fr

ed fr

ed fr

ed fr

ed from the axle housing.

om the axle housing.

om the axle housing.

om the axle housing.

om the axle housing.

9. Remove the axle shafts and carrier assembly from the

axle housing using the procedures as shown on

Page 8.

10.When carrier has been removed from the axle

housing, remove auxiliary pressure from the shift

cylinder.

CARRIER REMOVAL

Before carrier assembly can be removed from the axle

housing, the main differential lock must be engaged (in

the locked position). This must be done before the right-

side axle shaft is removed. Engaging (locking) the main

differential allows enough clearance for the clutch collar

to clear the carrier-to-housing mounting flange so removal

can be achieved.

NO

NO

NO

NO

NOTE: Locking of the main differ

TE: Locking of the main differ

TE: Locking of the main differ

TE: Locking of the main differ

TE: Locking of the main differential m

ential m

ential m

ential m

ential must be done

ust be done

ust be done

ust be done

ust be done

befor

befor

befor

befor

before r

e r

e r

e r

e remo

emo

emo

emo

emoving the right

ving the right

ving the right

ving the right

ving the right-side axle shaft. If the right

-side axle shaft. If the right

-side axle shaft. If the right

-side axle shaft. If the right

-side axle shaft. If the right-----

side axle shaft w

side axle shaft w

side axle shaft w

side axle shaft w

side axle shaft waaaaas r

s r

s r

s r

s remo

emo

emo

emo

emovvvvved for t

ed for t

ed for t

ed for t

ed for to

oo

oowing purpose

wing purpose

wing purpose

wing purpose

wing purposes,

s,

s,

s,

s,

rrrrreinst

einst

einst

einst

einstall it int

all it int

all it int

all it int

all it into the housing using pr

o the housing using pr

o the housing using pr

o the housing using pr

o the housing using procedur

ocedur

ocedur

ocedur

ocedure 2. fr

e 2. fr

e 2. fr

e 2. fr

e 2. from

om

om

om

om

the "Inst

the "Inst

the "Inst

the "Inst

the "Install Axle Shaft

all Axle Shaft

all Axle Shaft

all Axle Shaft

all Axle Shafts Aft

s Aft

s Aft

s Aft

s After T

er T

er T

er T

er To

oo

oowing". P

wing". P

wing". P

wing". P

wing". Page 2

age 2

age 2

age 2

age 26.

6.

6.

6.

6.

AIR PRESSURE METHOD

1. Drain lubricant from the axle assembly.

2. Raise the right-side rear drive wheel off the floor

using a hoist or jack.

3. Hold the right-side of the vehicle in the raised

position by using a jack stand under the right-

side housing spring seat.

4. Disconnect the drive shaft from the input yoke.

5. Disconnect air line from the differential lock

shift cylinder.

6. Connect an auxiliary air supply to the differen-

tial lock shift cylinder.

NO

NO

NO

NO

NOTE: If an auxiliary air suppl

TE: If an auxiliary air suppl

TE: If an auxiliary air suppl

TE: If an auxiliary air suppl

TE: If an auxiliary air supply is no

y is no

y is no

y is no

y is not a

t a

t a

t a

t avvvvvailable con-

ailable con-

ailable con-

ailable con-

ailable con-

tin

tin

tin

tin

tinue t

ue t

ue t

ue t

ue to use the "Man

o use the "Man

o use the "Man

o use the "Man

o use the "Manual Engaging Me

ual Engaging Me

ual Engaging Me

ual Engaging Me

ual Engaging Method" t

thod" t

thod" t

thod" t

thod" to lock

o lock

o lock

o lock

o lock

the main differntial.

the main differntial.

the main differntial.

the main differntial.

the main differntial.

7. Apply and hold air pressure to the shift cylinder.

This will move the clutch collar inward and engage

splines with the differential case splines,

locking the assembly.

8. To ensure differential clutch collar and case half have

engaged completely, rotate the drive pinion or the

right-side wheel.

MANUAL ENGAGING METHOD

NO

NO

NO

NO

NOTE: Use this me

TE: Use this me

TE: Use this me

TE: Use this me

TE: Use this method if auxiliary air is una

thod if auxiliary air is una

thod if auxiliary air is una

thod if auxiliary air is una

thod if auxiliary air is unavvvvvailabe.

ailabe.

ailabe.

ailabe.

ailabe.

1. Follow air pressure engagemant method through

step 5.

NO

NO

NO

NO

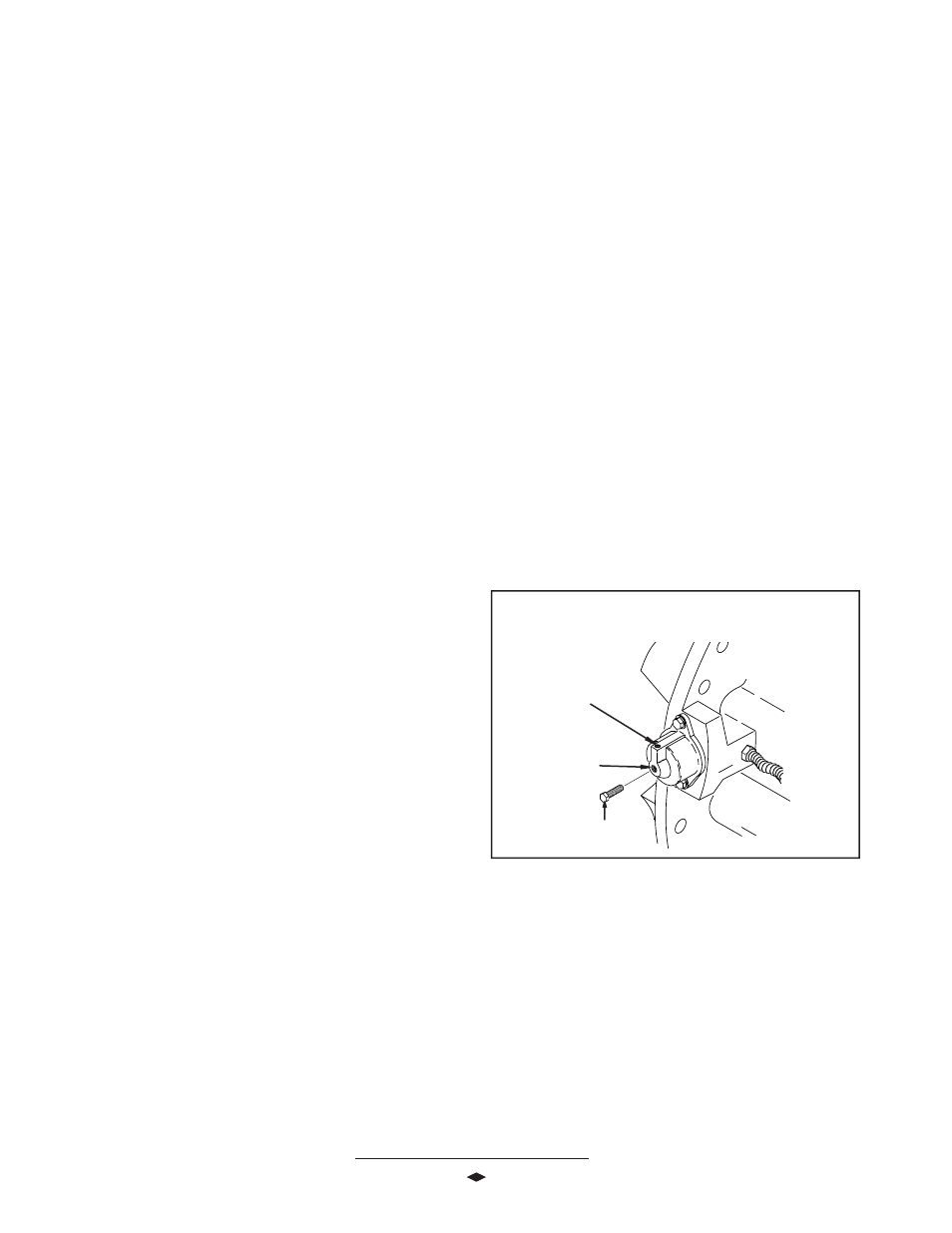

NOTE: R

TE: R

TE: R

TE: R

TE: Refer t

efer t

efer t

efer t

efer to F

o F

o F

o F

o Figur

igur

igur

igur

igure 1

e 1

e 1

e 1

e 14 for the follo

4 for the follo

4 for the follo

4 for the follo

4 for the following st

wing st

wing st

wing st

wing steps.

eps.

eps.

eps.

eps.

2. Remove plug from the hole in the center of the shift

cylinder cover.

3. Install an M12 x 1.50 bolt in the cylinder air-port,

same hole the plug was in, to manually engage the

differential.

Continued On Ne

Continued On Ne

Continued On Ne

Continued On Ne

Continued On Next P

xt P

xt P

xt P

xt Page

age

age

age

age

FFFFFigur

igur

igur

igur

igure 1

e 1

e 1

e 1

e 14

4

4

4

4

Air Supply

Air Supply

Air Supply

Air Supply

Air Supply

Inlet

Inlet

Inlet

Inlet

Inlet

Air Shift

Air Shift

Air Shift

Air Shift

Air Shift

C

C

C

C

Cylinder

ylinder

ylinder

ylinder

ylinder

Manual Eng

Manual Eng

Manual Eng

Manual Eng

Manual Engaging

aging

aging

aging

aging

M1

M1

M1

M1

M12 X 1.5

2 X 1.5

2 X 1.5

2 X 1.5

2 X 1.50 Bolt

0 Bolt

0 Bolt

0 Bolt

0 Bolt

DIFFERENTIAL LOCK

MANUAL ENGAGEMENT DIAGRAM