Pinion assembl – Spicer Drive Axles Service Manual Wheel Reduction Drive Axles (EA-50) User Manual

Page 17

15

PINION ASSEMBL

PINION ASSEMBL

PINION ASSEMBL

PINION ASSEMBL

PINION ASSEMBLY

Y

Y

Y

Y

Me

Me

Me

Me

Method A

thod A

thod A

thod A

thod A uses a pull scale and a strong cord approxi-

mately 8 ft. long. (See Item 11). Me

Me

Me

Me

Method B

thod B

thod B

thod B

thod B uses a Lb-in

torque wrench. Both methods measure torque to rotate.

(See Item 12).

1

1

1

1

11.

1.

1.

1.

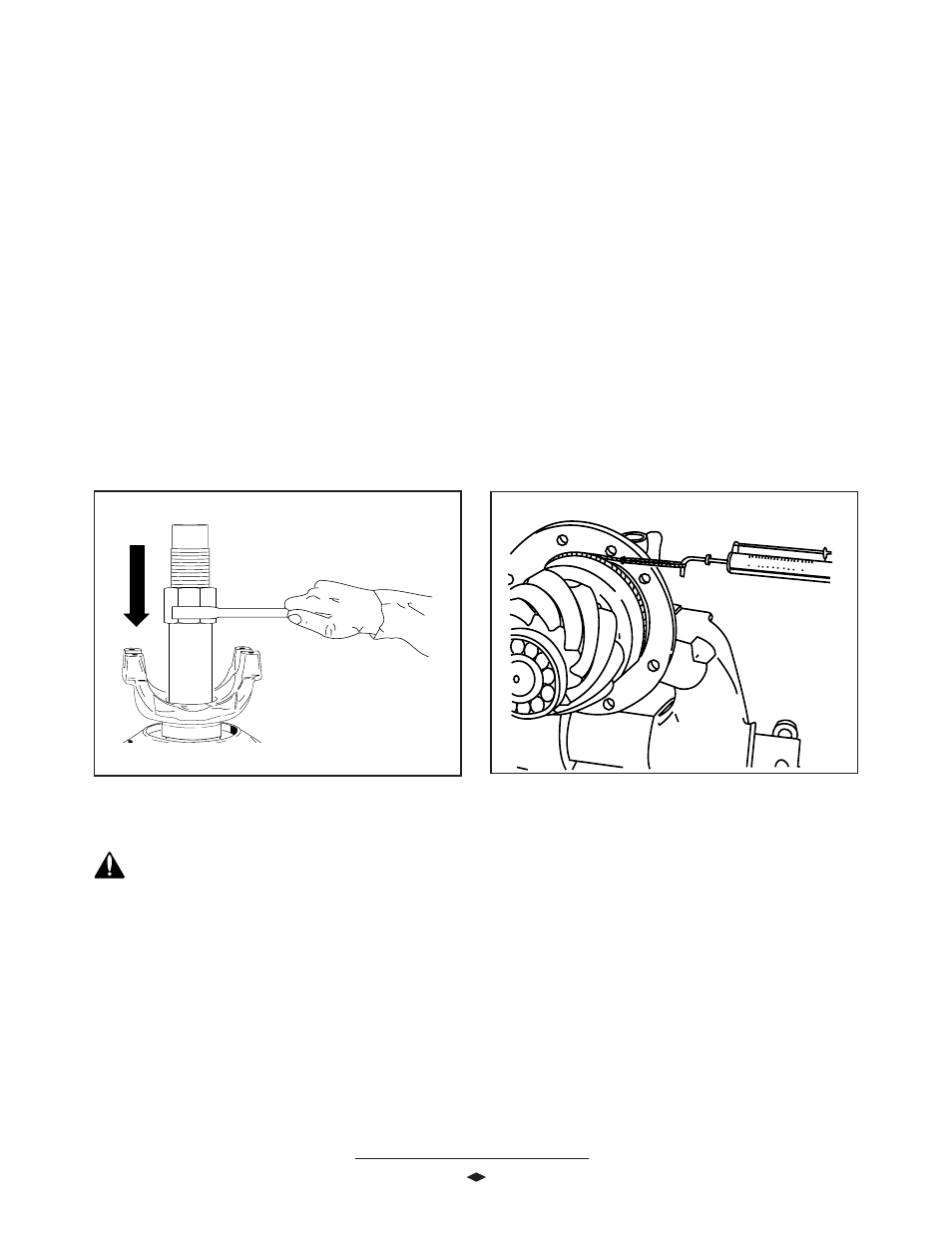

1. Me

Me

Me

Me

Method A:

thod A:

thod A:

thod A:

thod A: To measure torque-to-rotate with the

spring scale, clamp the end yoke horizontally in a

soft-jawed vise. Attach one end of the cord to a bolt

hole in the pinion cage, wrap cord around pinion

cage and attach the outer end of the cord to the

spring scale. Rotate pinion cage by pulling scale.

Read scale during fourth revolution. Scale reading

must be between 3-10 Lbs (1.4-4.5 Kg) See

See

See

See

See

FFFFFigur

igur

igur

igur

igure 7

e 7

e 7

e 7

e 7.....

8.

8.

8.

8.

8. Place pinion bearing cage onto inner pinion

bearing.

9.

9.

9.

9.

9. Install the outer pinion bearing cone onto pinion.

1

1

1

1

10.

0.

0.

0.

0. Without installing seal, install end yoke onto pinion

using yoke installer service tool. See F

See F

See F

See F

See Figur

igur

igur

igur

igure 6.

e 6.

e 6.

e 6.

e 6. This

will allow proper setting of pinion preload. Secure

yoke with a Yoke and Flange Holding Bar or an

equivalent tool. Install pinion nut and washer.

Torque pinion nut to 900-1,200 Lb-Ft (1,220-

1,627 N-m).

NO

NO

NO

NO

NOTE: Inspect end y

TE: Inspect end y

TE: Inspect end y

TE: Inspect end y

TE: Inspect end yok

ok

ok

ok

oke seal sur

e seal sur

e seal sur

e seal sur

e seal surface for gr

face for gr

face for gr

face for gr

face for groo

oo

oo

oo

oovvvvveeeeesssss

caused b

caused b

caused b

caused b

caused by lip of seal. If gr

y lip of seal. If gr

y lip of seal. If gr

y lip of seal. If gr

y lip of seal. If groo

oo

oo

oo

oovvvvveeeees can be de

s can be de

s can be de

s can be de

s can be detttttect

ect

ect

ect

ected with

ed with

ed with

ed with

ed with

fingernail, it should be r

fingernail, it should be r

fingernail, it should be r

fingernail, it should be r

fingernail, it should be replaced.

eplaced.

eplaced.

eplaced.

eplaced.

CA

CA

CA

CA

CAUTION: The pinion cage should be r

UTION: The pinion cage should be r

UTION: The pinion cage should be r

UTION: The pinion cage should be r

UTION: The pinion cage should be ro

oo

ootttttaaaaattttted

ed

ed

ed

ed

periodicall

periodicall

periodicall

periodicall

periodically while tight

y while tight

y while tight

y while tight

y while tightening the pinion n

ening the pinion n

ening the pinion n

ening the pinion n

ening the pinion nut t

ut t

ut t

ut t

ut to sea

o sea

o sea

o sea

o seattttt

and align the pinion bearings.

and align the pinion bearings.

and align the pinion bearings.

and align the pinion bearings.

and align the pinion bearings.

There are two methods of measuring pinion bearing

preload and both are acceptable. Mechanic's preference

and available tools should determine which method

is used.

(Continued on Ne

(Continued on Ne

(Continued on Ne

(Continued on Ne

(Continued on Next P

xt P

xt P

xt P

xt Page)

age)

age)

age)

age)

FFFFFigur

igur

igur

igur

igure 6

e 6

e 6

e 6

e 6

FFFFFigur

igur

igur

igur

igure 7

e 7

e 7

e 7

e 7