Gear contact patterns, Ring gear and pinion, Correct gear p – Spicer Drive Axles Service Manual Wheel Reduction Drive Axles (EA-50) User Manual

Page 23: Incorrect gear p

21

RING GEAR AND PINION

RING GEAR AND PINION

RING GEAR AND PINION

RING GEAR AND PINION

RING GEAR AND PINION

TOOTH CONT

TOOTH CONT

TOOTH CONT

TOOTH CONT

TOOTH CONTACT P

ACT P

ACT P

ACT P

ACT PA

A

A

A

ATTERN

TTERN

TTERN

TTERN

TTERN

LENGTHWISE

LENGTHWISE

LENGTHWISE

LENGTHWISE

LENGTHWISE

BEARING AR

BEARING AR

BEARING AR

BEARING AR

BEARING ARC

C

C

C

C

T

T

T

T

TOE

OE

OE

OE

OE

HEEL

HEEL

HEEL

HEEL

HEEL

The following procedures are to be used to establish

proper gear tooth pattern after assembly of the carrier is

complete.

NO

NO

NO

NO

NOTE: If ma

TE: If ma

TE: If ma

TE: If ma

TE: If matched se

tched se

tched se

tched se

tched settttts ar

s ar

s ar

s ar

s are being r

e being r

e being r

e being r

e being reused, mea

eused, mea

eused, mea

eused, mea

eused, measur

sur

sur

sur

sureeeee

and r

and r

and r

and r

and recor

ecor

ecor

ecor

ecord backla

d backla

d backla

d backla

d backlash befor

sh befor

sh befor

sh befor

sh before disa

e disa

e disa

e disa

e disassembl

ssembl

ssembl

ssembl

ssemblyyyyy, and r

, and r

, and r

, and r

, and rea

ea

ea

ea

eas-

s-

s-

s-

s-

semble t

semble t

semble t

semble t

semble to the same backla

o the same backla

o the same backla

o the same backla

o the same backlash. This will ma

sh. This will ma

sh. This will ma

sh. This will ma

sh. This will match ring

tch ring

tch ring

tch ring

tch ring

and pinion gear

and pinion gear

and pinion gear

and pinion gear

and pinion gears t

s t

s t

s t

s to the e

o the e

o the e

o the e

o the est

st

st

st

stablished w

ablished w

ablished w

ablished w

ablished wear pa

ear pa

ear pa

ear pa

ear patttttttttterns.

erns.

erns.

erns.

erns.

Hand r

Hand r

Hand r

Hand r

Hand rolled pa

olled pa

olled pa

olled pa

olled patttttttttterns will co

erns will co

erns will co

erns will co

erns will covvvvver le

er le

er le

er le

er less ar

ss ar

ss ar

ss ar

ss area than the

ea than the

ea than the

ea than the

ea than the

gear pa

gear pa

gear pa

gear pa

gear pattttttttttern e

ern e

ern e

ern e

ern est

st

st

st

stablished b

ablished b

ablished b

ablished b

ablished by pr

y pr

y pr

y pr

y preeeeevious service.

vious service.

vious service.

vious service.

vious service.

STEP 1. Paint 1/4 ring gear with marking compound on

both the drive and coast side.

STEP 2. Apply drag load to ring gear and rotate pinion

so that ring gear completes one revolution in

each direction.

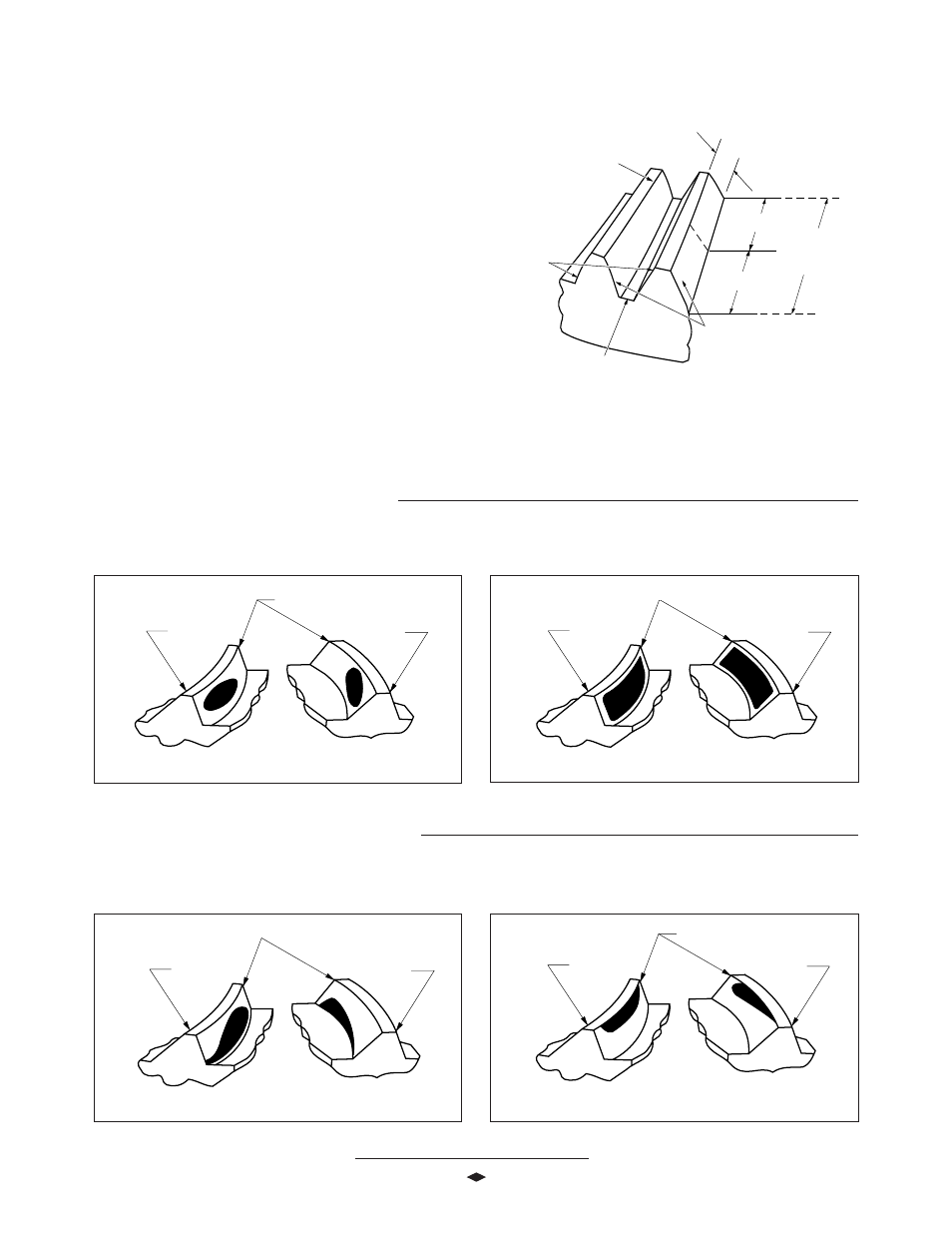

CORRECT GEAR P

CORRECT GEAR P

CORRECT GEAR P

CORRECT GEAR P

CORRECT GEAR PA

A

A

A

ATTERNS

TTERNS

TTERNS

TTERNS

TTERNS

TOE

TOE

DRIVE SIDE

(CONVEX)

COAST SIDE

(CONCAVE)

COAST SIDE

(CONCAVE)

DRIVE SIDE

(CONVEX)

HEA

HEA

HEA

HEA

HEAVIL

VIL

VIL

VIL

VILY L

Y L

Y L

Y L

Y LO

O

O

O

OADED

ADED

ADED

ADED

ADED

LIGHTL

LIGHTL

LIGHTL

LIGHTL

LIGHTLY L

Y L

Y L

Y L

Y LO

O

O

O

OADED

ADED

ADED

ADED

ADED

HEEL

HEEL

HEEL

HEEL

TOE

HEEL

HEEL

COAST SIDE

(CONCAVE)

DRIVE SIDE

(CONVEX)

TOE

HEEL

HEEL

COAST SIDE

(CONCAVE)

DRIVE SIDE

(CONVEX)

HEA

HEA

HEA

HEA

HEAVIL

VIL

VIL

VIL

VILY L

Y L

Y L

Y L

Y LO

O

O

O

OADED

ADED

ADED

ADED

ADED

LIGHTL

LIGHTL

LIGHTL

LIGHTL

LIGHTLY L

Y L

Y L

Y L

Y LO

O

O

O

OADED

ADED

ADED

ADED

ADED

INCORRECT GEAR P

INCORRECT GEAR P

INCORRECT GEAR P

INCORRECT GEAR P

INCORRECT GEAR PA

A

A

A

ATTERNS

TTERNS

TTERNS

TTERNS

TTERNS

CO

CO

CO

CO

COAS

AS

AS

AS

AST SIDE

T SIDE

T SIDE

T SIDE

T SIDE

DRIVE SIDE

DRIVE SIDE

DRIVE SIDE

DRIVE SIDE

DRIVE SIDE

R

RR

R

ROO

OO

OO

OO

OOT

T

T

T

T

T

T

T

T

TOP LAND

OP LAND

OP LAND

OP LAND

OP LAND

PR

PR

PR

PR

PROFILE

OFILE

OFILE

OFILE

OFILE