Differential assembly, Differential assembl – Spicer Drive Axles Service Manual Wheel Reduction Drive Axles (EA-50) User Manual

Page 21

19

3.

3.

3.

3.

3. Apply a small amount of gear lubricant to all mating

surfaces. This will aid in assembly by keeping parts

together and providing initial lubrication.

4.

4.

4.

4.

4. Place thrust washer and side gear in differential case

flange half.

5.

5.

5.

5.

5. Assemble pinion mates and thrust washers onto

differential cross shaft. Place assembly into flange

half differential case.

6.

6.

6.

6.

6. Place remaining side gear and thrust washer in

position on differential pinion mates.

7

7

7

7

7..... Assemble case halves, making sure match marks are

lined up.

8.

8.

8.

8.

8. If reinstalling used bolts, clean threads and apply

Loctite #277. Install differential case bolts and

torque evenly to 160-180 Lb-Ft (217- 244 N-m).

DIFFERENTIAL ASSEMBL

DIFFERENTIAL ASSEMBL

DIFFERENTIAL ASSEMBL

DIFFERENTIAL ASSEMBL

DIFFERENTIAL ASSEMBLY

Y

Y

Y

Y

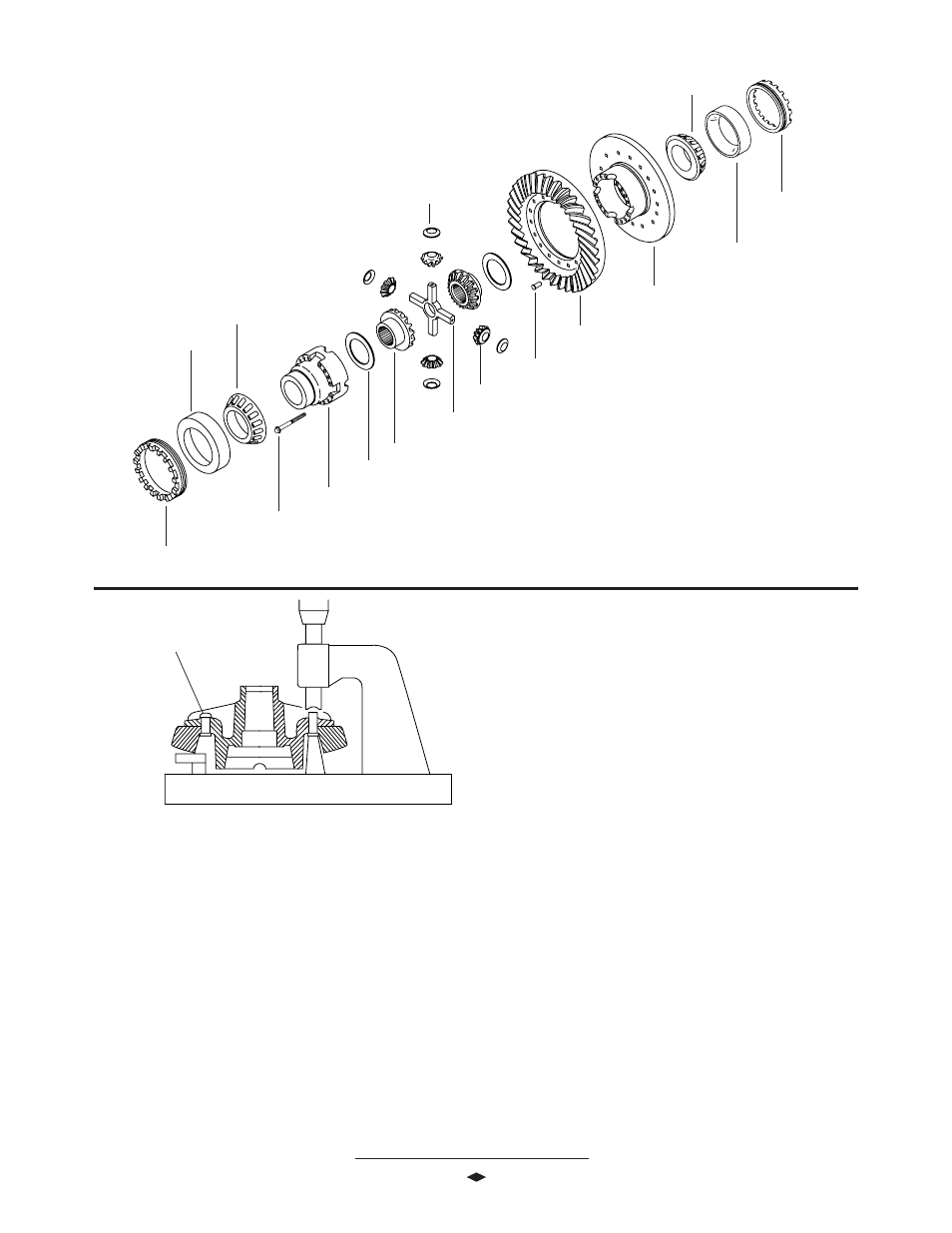

Thrust Washer

Differential Side Gear

Differential Bearing Cone

Differential Bearing

Adjusting Ring

Differential Case Half

Differential Pinion Mate

Ring Gear

Differential Case Flange Half

Thrust Washer

Differential Bearing Cup

Differential Bearing Cone

Differential Case Bolt

(160 - 180 Lb-Ft)

(217 - 244 N-m)

Differential Cross Shaft

Differential Bearing Cup

Differential Bearing

Adjusting Ring

Corr

Corr

Corr

Corr

Correct riv

ect riv

ect riv

ect riv

ect rivet head shape

et head shape

et head shape

et head shape

et head shape

when pr

when pr

when pr

when pr

when properly compr

operly compr

operly compr

operly compr

operly compreeeeessed

ssed

ssed

ssed

ssed

Ring Gear Rivet (45-50 tons)

(41-45 metric tonnes)

Differ

Differ

Differ

Differ

Differential Assembly Complet

ential Assembly Complet

ential Assembly Complet

ential Assembly Complet

ential Assembly Completeeeee

NO

NO

NO

NO

NOTE: Ring gear bolt kit

TE: Ring gear bolt kit

TE: Ring gear bolt kit

TE: Ring gear bolt kit

TE: Ring gear bolt kits ar

s ar

s ar

s ar

s are a

e a

e a

e a

e avvvvvailable a

ailable a

ailable a

ailable a

ailable as a r

s a r

s a r

s a r

s a replace-

eplace-

eplace-

eplace-

eplace-

ment for ring gear riv

ment for ring gear riv

ment for ring gear riv

ment for ring gear riv

ment for ring gear riveeeeettttts, see par

s, see par

s, see par

s, see par

s, see parttttts list man

s list man

s list man

s list man

s list manual for par

ual for par

ual for par

ual for par

ual for parttttt

n

nn

nnumber informa

umber informa

umber informa

umber informa

umber information.

tion.

tion.

tion.

tion.

1.

1.

1.

1.

1. If ring gear was removed from the differential case,

reinstall it at this time. Bolt ring gear to differential

case in three places, 120° apart, before compressing

rivet; this will eliminate ring gear runout. Use a

hydraulic or mechanical press and riveting fixture.

Pressure requirement per rivet is 45-50 U.S. tons or

(41-45 metric tonnes).

2.

2.

2.

2.

2. Press bearing cones onto differential case halves.

Place bearing cups on cones during remainder of

assembly to prevent damage of bearings.