2 rack mounting the instrument, 3 installing the sensor, Rack mounting the instrument – American Magnetics 187 Self-Compensating Liquid Level Controller User Manual

Page 19: Installing the sensor, Installation, Warning

8

Installation

Installing the sensor

2.2 Rack Mounting the Instrument

If the instrument has a rack mount chassis, follow the following procedure:

a. Attach the rack mount adapter pieces to the instrument by first

removing the four screws on the side of the instrument that

attach the cover to the chassis. Attach the rack mount adapter

pieces to the sides of the instrument by reinstalling the screws.

b. Install the instrument in a 19" rack by securing the front panel

to the rail in each of the four corners with mounting hardware

supplied by the cabinet manufacturer.

Warning

Do not remove the cabinet feet and then reinsert the original screws.

Doing so could present a severe life-threatening electrical hazard. If

removal of the cabinet feet is desired, replace the original screws

with screws not to exceed 1/4" in length. Screws longer than 1/4"

will contact and damage the printed circuit board inside the unit.

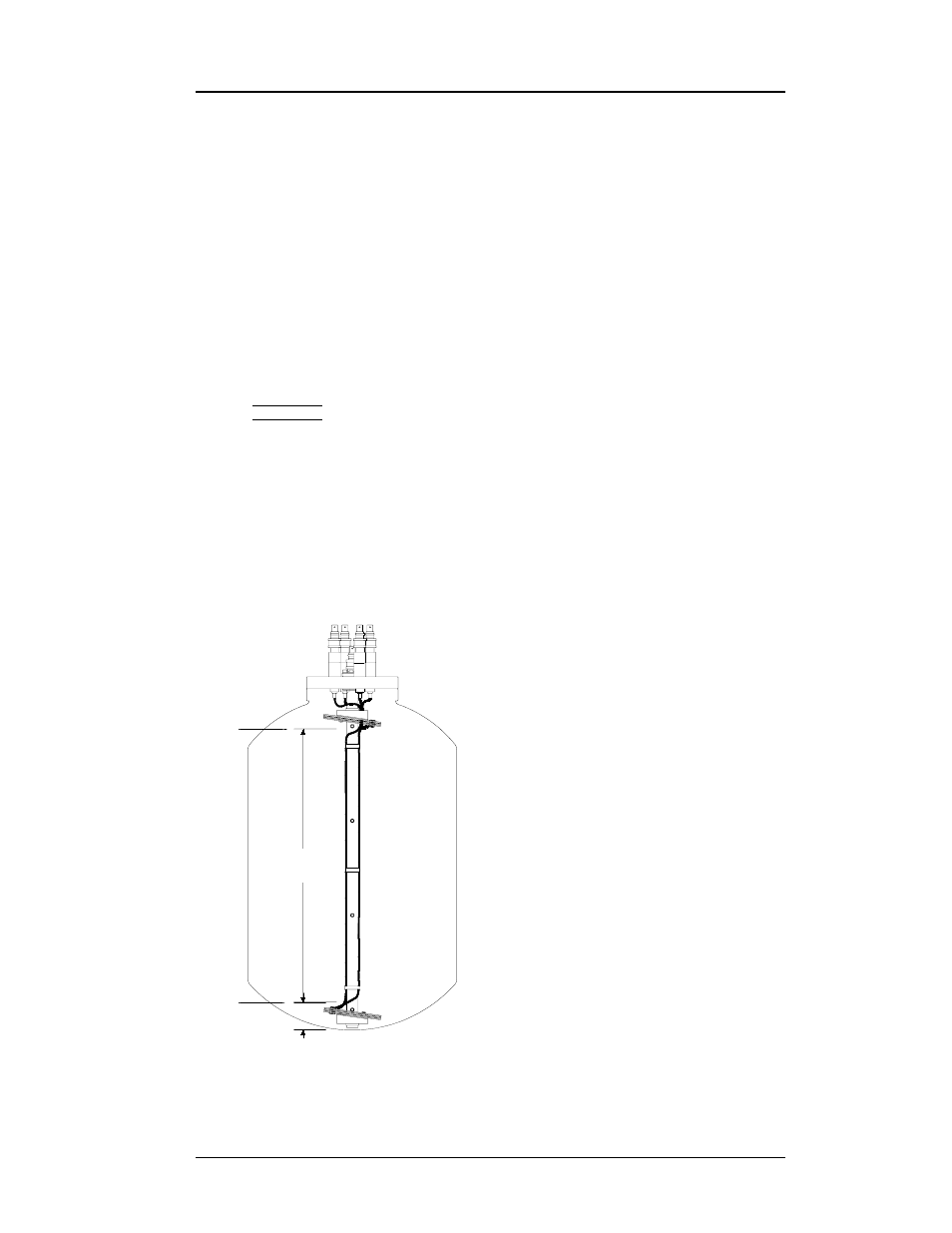

2.3 Installing the Sensor

Exercise care when installing the

sensor since dents, crimps, bends or

other physical distortions in the

cylindrical and plate sensors will

change electrical characteristics

and possibly cause calibration

errors and/or disruption of proper

instrument operation. It is also

important to ensure that the sensor

is installed in a vertical orientation

for optimal operation of the sensors.

Make a note of the 0% and 100%

points of the target vessel per

diagram at left. Before installing

the sensor and before filling the

target vessel, the user may first

want to review the Operation

section—especially the zero offset

and measured span length settings

discussed on page 14.

Drawings will be provided for

custom sensor or mounting flange

designs.

MAXIMUM

MEASURED

SPAN

MINIMUM

ZERO

OFFSET

100%

0%