Tool radius compensation feature, Sign for the length difference dl, I - 3 milling specific oper ations – ACU-RITE 200S User Manual

Page 37

200S

23

I - 3 Milling Specific Oper

ations

Tool Radius Compensation feature

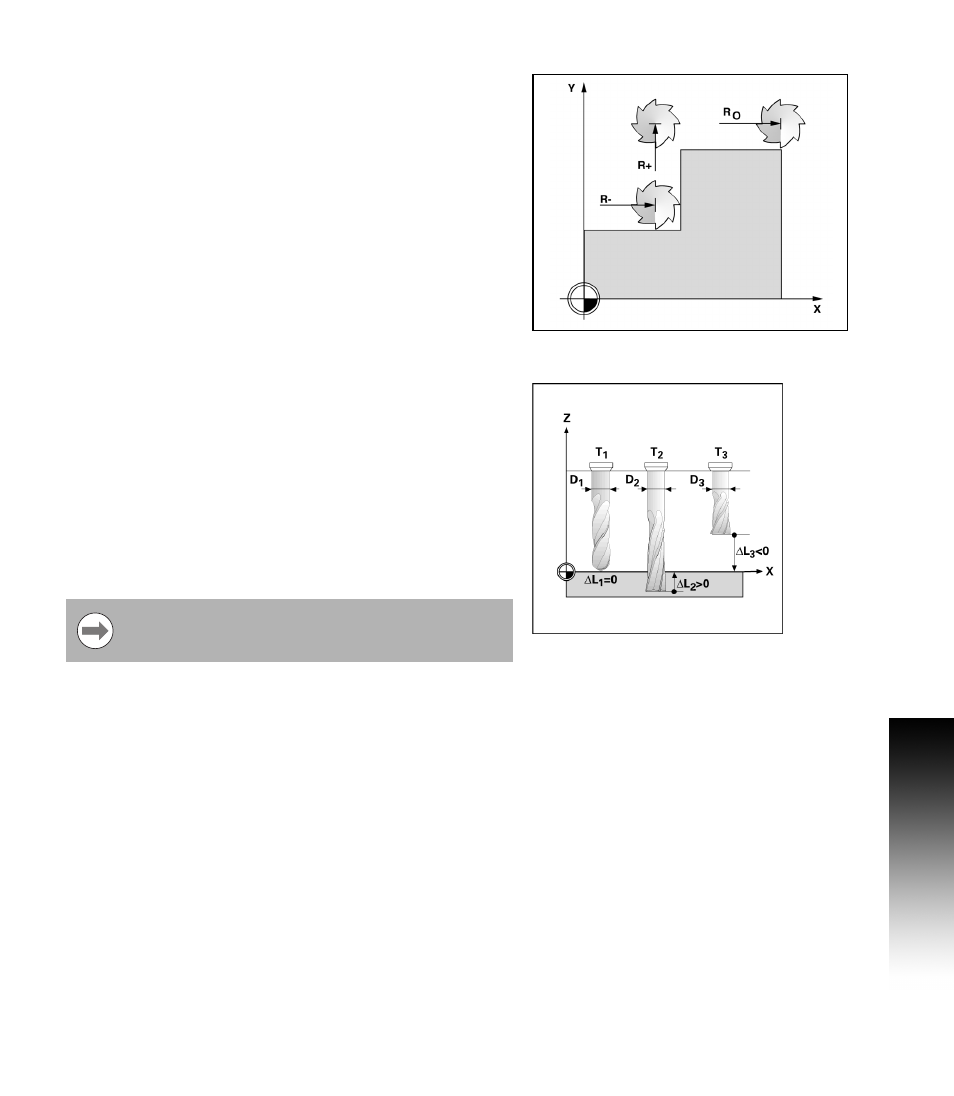

This allows you to enter workpiece dimensions directly from the

drawing. R represents the tool radius, and examples of the R values

are shown in this figure. The displayed distance to go is then

automatically lengthened R+, or shortened R- by the value of the tool

radius. For more information see "Presets" on page 32.

The length offset may be entered as a known value or the 200S may

determine the offset automatically. The tool length is the difference in

length

ΔL between the tool and the reference tool. The length

difference is indicated with the “

Δ”symbol. The reference tool is

indicated by T1.

Sign for the length difference

ΔL

If the tool is longer than the reference tool:

ΔL > 0 (+).

If the tool is shorter than the reference tool:

ΔL < 0 (–).

The length offset may be entered as a known value, or the 200S may

determine the offset automatically. To have the 200S determine a

tool’s length offset involves touching the tip of each tool to a common

reference surface. This allows the 200S to determine the difference

between the length of each tool.

Move the tool until it’s tip is touching the reference surface. Press the

TEACH LENGTH soft key. The 200S will calculate an offset relative to

this surface. Repeat the procedure for each additional tool using the

same reference surface.

Only the tools set using the same reference surface may be

changed without having to reset the datum.