Venting installation tip, Venting configuration, Venting installation tips – Raypak MVB 5042004 User Manual

Page 28: Venting configurations

28

• 75’ of straight flue pipe

• 65’ of straight flue pipe and one elbow

•

55’ of straight flue pipe and two elbows

•

45’ of straight pipe and three elbows

The vent cap is not considered in the overall length of

the venting system.

The vent must be installed to prevent flue gas leakage.

Care must be taken during assembly to ensure that all

joints are sealed properly and are airtight. The vent

must be installed to prevent the potential accumulation

of condensate in the vent pipes. It is required that:

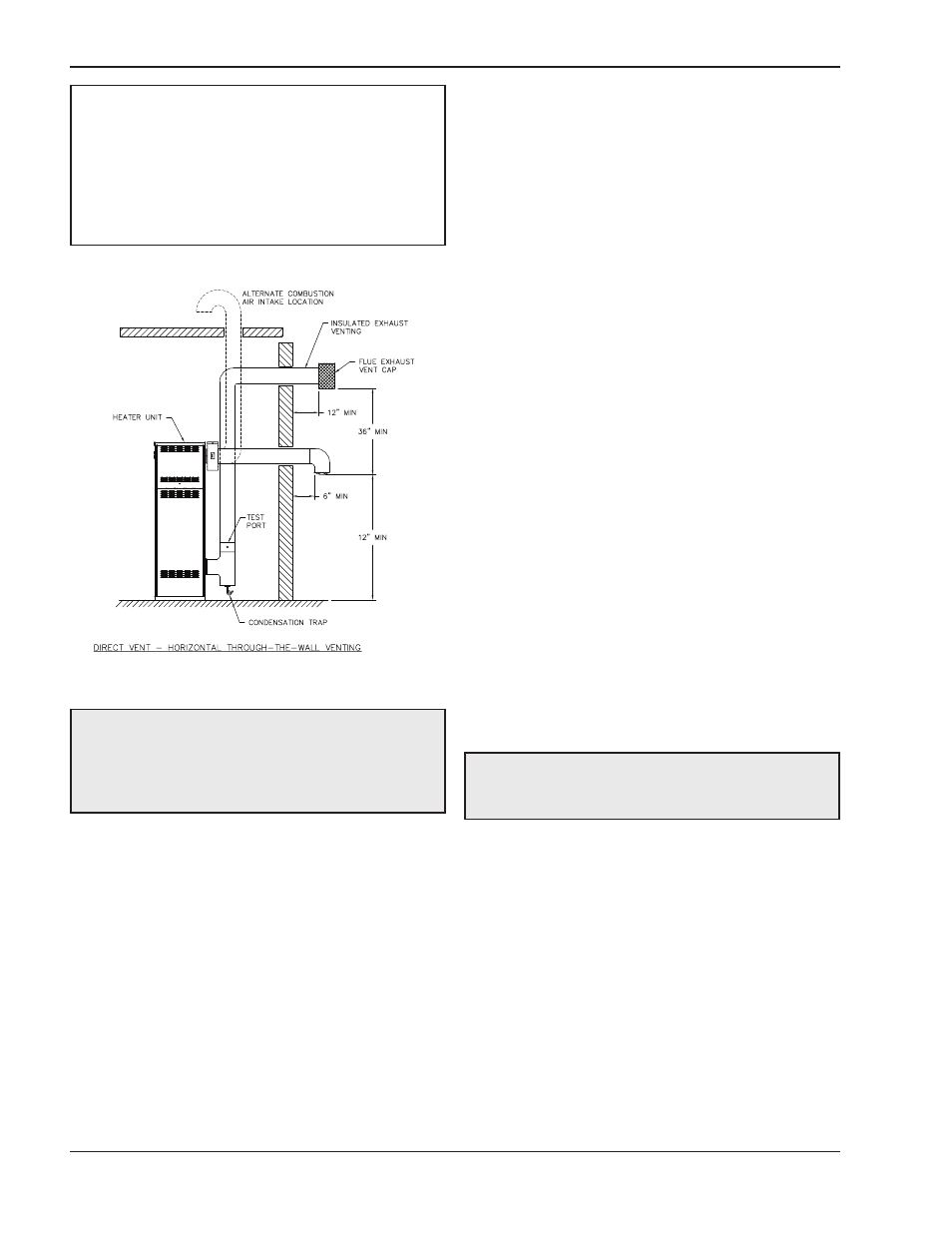

1. The vent must be installed with a condensate

drain located in proximity to the heater as directed

by the vent manufacturer.

2. The vent must be installed with a slight upward

slope of not less than 1/4 inch per foot of horizon-

tal run to the vent terminal.

3. The vent must be insulated through the length of

the horizontal run.

Termination

The flue direct vent cap MUST be mounted on the ex-

terior of the building. The direct vent cap cannot be

installed in a well or below grade. The direct vent cap

must be installed at least 1 ft above ground level and

above normal snow levels. The Raypak-approved

stainless steel flue direct vent cap must be used (sales

order option D-15). The vent terminal must be located

NO CLOSER than 12” off the wall.

Direct Vent—Vertical

Installation

These installations utilize the heater-mounted blower

to draw combustion air from outdoors and force the

heated flue products through the vent pipe under posi-

tive pressure. The vent material must be in

accordance with the above instructions for vent mate-

rials. Vent material must be listed by a nationally

recognized test agency.

The connection from the appliance flue to the stack

must be as direct as possible and should be the same

size or larger than the vent outlet.

WARNING: No substitutions of flue pipe or vent

cap material are allowed. Such substitutions would

jeopardize the safety and health of inhabitants.

NOTE: While a drain connection is required in the

vent of all Cat. III horizontal MVB installations, the

drain can be accomplished in several different ways.

The figures in this manual show the drain in a vent

tee, however, this can also be accomplished using

an inline collector for condensing stacks or an inline

vertical or horizontal collector available from several

of the listed vent manufacturers.

Fig. 27: Horizontal Through-the-Wall Direct Venting

CAUTION: This venting system requires the

installation of a condensate drain in the vent piping

per the vent manufacturer’s instructions. Failure to

install a condensate drain in the venting system will

void all warranties on this heater.

Installation

These installations utilize the heater-mounted blower

to vent the combustion products to the outdoors.

Combustion air is taken from inside the room and the

vent is installed horizontally through the wall to the out-

doors. Adequate combustion and ventilation air must

be supplied to the equipment room in accordance with

the NFGC (U.S.) or B149 (Canada).

The total length of the horizontal through-the-wall flue

system should not exceed 75 equivalent ft in length. If

horizontal run exceeds 75 equivalent ft, an appropri-

ately sized variable-speed extractor must be used.

Each elbow used is equal to 10 ft of straight pipe. This

will allow installation in one of the four following

arrangements: