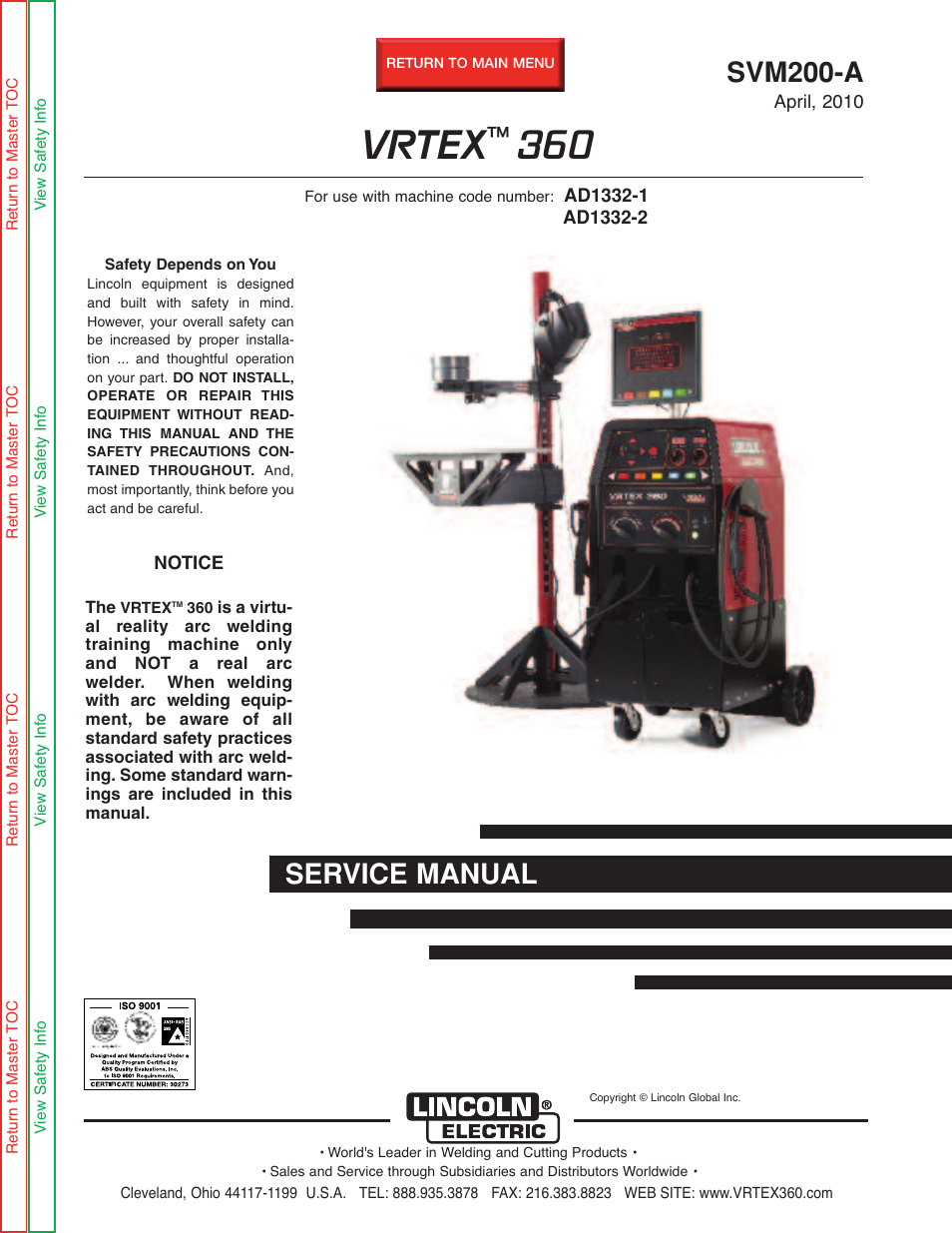

Lincoln Electric VRTEXTM 360 SVM200-A User Manual

Vrtex, Svm200-a, Service manual

Table of contents

Document Outline

- Master Table of Content

- Safety

- Section A - Installation

- Section B - Operation

- Section D - Maintenance

- Section E - Theory of Operation

- Section F - Troubleshooting & Repair

- Symptoms

- The VRTEXTM 360 does not turn on when the On Switch is pushed. The green indicator light does not light.

- The VRTEXTM 360 does not power up when the ON Switch is pushed. The green indicator light does come on but does NOT stay on when the ON Switch is released.

- The VRTEXTM 360 does not power up when the ON Switch is pushed. The green indicator light does come on and stays on.

- The Video Monitor does not function correctly. But the Helmet is working correctly and providing feedback information to the user.

- The Display P.C. Board does not function correctly. The VRTEXTM 360 seems to work correctly.

- Some of the User Interface Controls and/or Indicators do not function.

- All of the User Interface Controls and Indicators do not function.

- The user is not receiving any visual or audio feedback information in the helmet (FMD).

- The VRTEXTM 360 does not function correctly in the SMAW(stick) mode. But it functions correctly in the VR GMAW mode.

- The VRTEXTM 360 does not function correctly in the GMAW mode. It works correctly in the VRSMAW (stick) mode.

- There is jitter or shaking in the Helmet display and Monitor.

- The CPU constantly looses the current time and date. At initial boot-up the monitor reads “CMOS” battery failed.

- As viewed through the helmet and the monitor, the entire stand assembly appears in the middle of the screen and the environment does not move.

- The weld coupon image is a different configuration than the physical coupon.

- The arm and/or table are different than the visuals in the software.

- When the check settings are activated the incorrect settings appear.

- Holding the green button in does not shut down the VRTEXTM 360

- Sometimes the view in the helmet seems to shake, wobble or jitter.

- The students' reports are notaccessible.

- Previous weld pass data is not accessible on the LASER screen.

- Some or none of the welding parameters, defects, or discontinuities are graphing on the LASER screen.

- The user is not sure of which tolerances they are using.

- Section G - Electrical Diagrams