Profibus interface center, Spc3 – Siemens SPC3 User Manual

Page 58

PROFIBUS Interface Center

SPC3

Page 56

V1.3

SPC3 Hardware Description

2003/04

Copyright (C) Siemens AG 2003. All rights reserved.

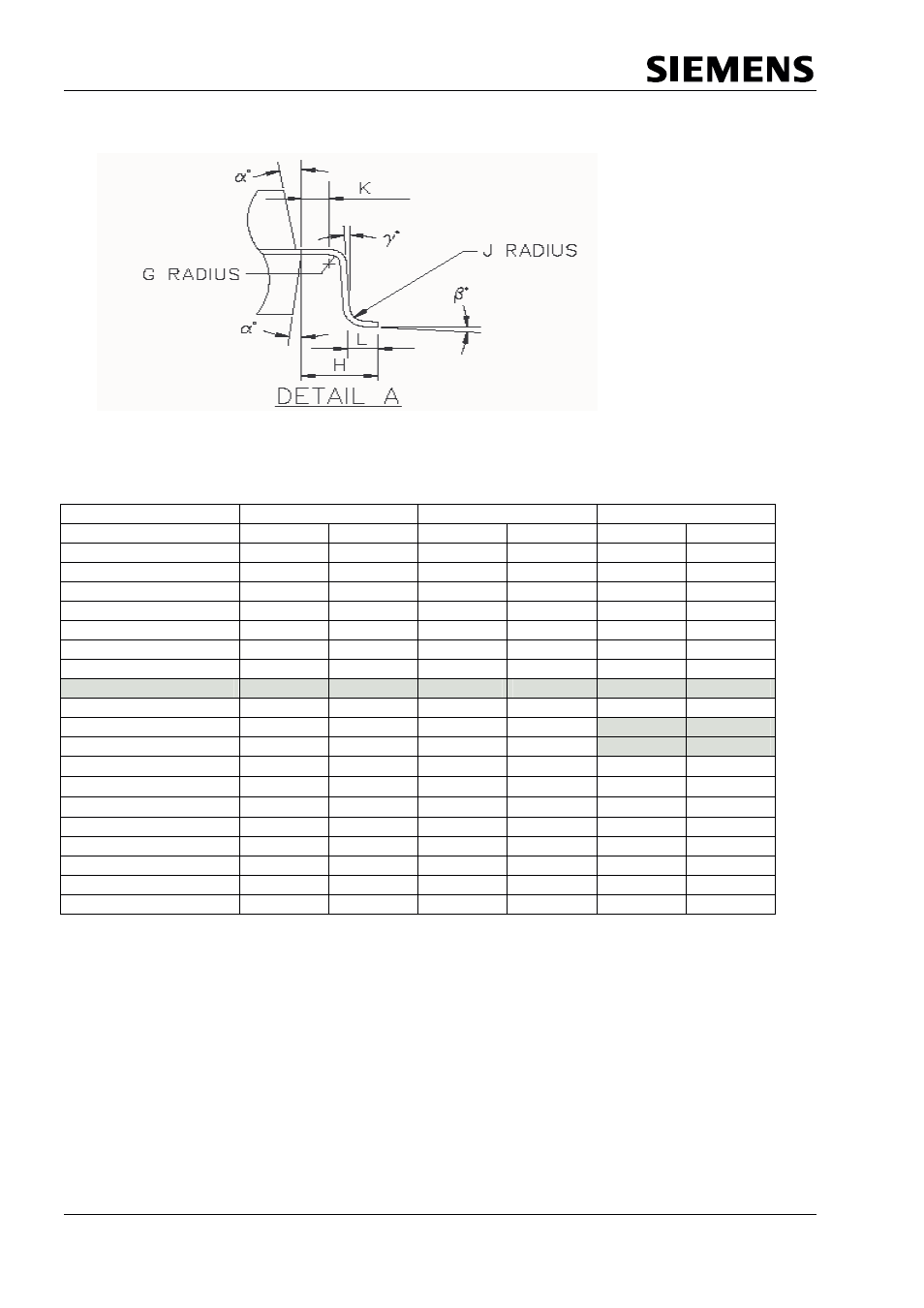

Symbol

Min

Typ

Max

AMI-Vers.

ST-Vers.

AMI-Vers.

ST-Vers.

AMI-Vers.

ST-Vers.

A

-

-

2.13

-

2.35

2.45

A1

0.10

0.25

0.15

-

0.25

-

A2

1.95

1.90

2.00

2.00

2.10

2.10

D

13.65

13.65

13.90

13.90

14.15

14.15

D1

9.90

9.90

10.00

10.00

10.10

10.10

E

13.65

13.65

13.90

13.90

14.15

14.15

E1

9.90

9.90

10.00

10.00

10.10

10.10

L

0.65

0.78

0.80

0.88

0.95

1.03

e BASIC

-

-

0.80

0.80

-

-

B

0.30

0.30

-

0.35

0.45

0.40

c

0.13

-

-

-

0.23

0.17

α

αα

α

°

12

-

-

10

16

-

ββββ

°

0

0

-

-

7

7

γγγγ

°

0

1

-

5

-

9

G

0.13

-

-

0.20

-

-

H

-

-

1.95

-

-

-

J

-

-

0.30

0.30

-

-

K

0.40

-

-

-

-

-

2H (Footprint)

-

-

3.90

3.90

-

-

8.5.8 Processing Instructions

ESD protective measures must be maintained for all electronic components.

SPC3 is a cracking-endangered component that must be handled as such.

A drying process must be carried out before SPC3 is processed. The component must be dried at 125o C

for 24 hours and then be processed within 48 hours. This drying process may be carried out once only

because the component is soldered.

It must also be ensured that the SPC3’s connections are not bent. Flawless processing can be guaranteed

only if a planity of less than 0.1 mm is ensured. SPC3 is released for infrared soldering with a soldering

profile according to CECC00802.