Sharp Digital Laser Copier/Printer AR-5127 User Manual

Page 36

AR-5127 SIMULATION 8 - 8

Operation/procedure

Press the [OK] key.

ON/OFF operation of the heater lamp is repeated 5 times in an interval

of 500ms.

Operation/procedure

Press the [OK] key.

The copy lamp lights up for 10 sec.

When 10 sec passed, the copy lamp is turned OFF.

Operation/procedure

The names of the loads which can be operated are displayed. Select

the load to be checked with the 10-key.

The motor for 10sec, the solenoid ON for 500msec, OFF for 500msec.

(20 times)

The lift-up motor operates only when the tray is opened.

Operation/procedure

The names of the loads which can be operated are displayed. Select

the load to be checked with the key.

The selected fan motor is highlighted and it rotates for 10sec.

Operation/procedure

Select with the 10-key.

Press [CA] key, and the simulation will be terminated and copying will

be made with the set contents.

5-2

Purpose

Operation test/check

Function

(Purpose)

Used to check the operation of the heater lamp and the

control circuit.

Section

Fixing (Fusing)

Item

Operation

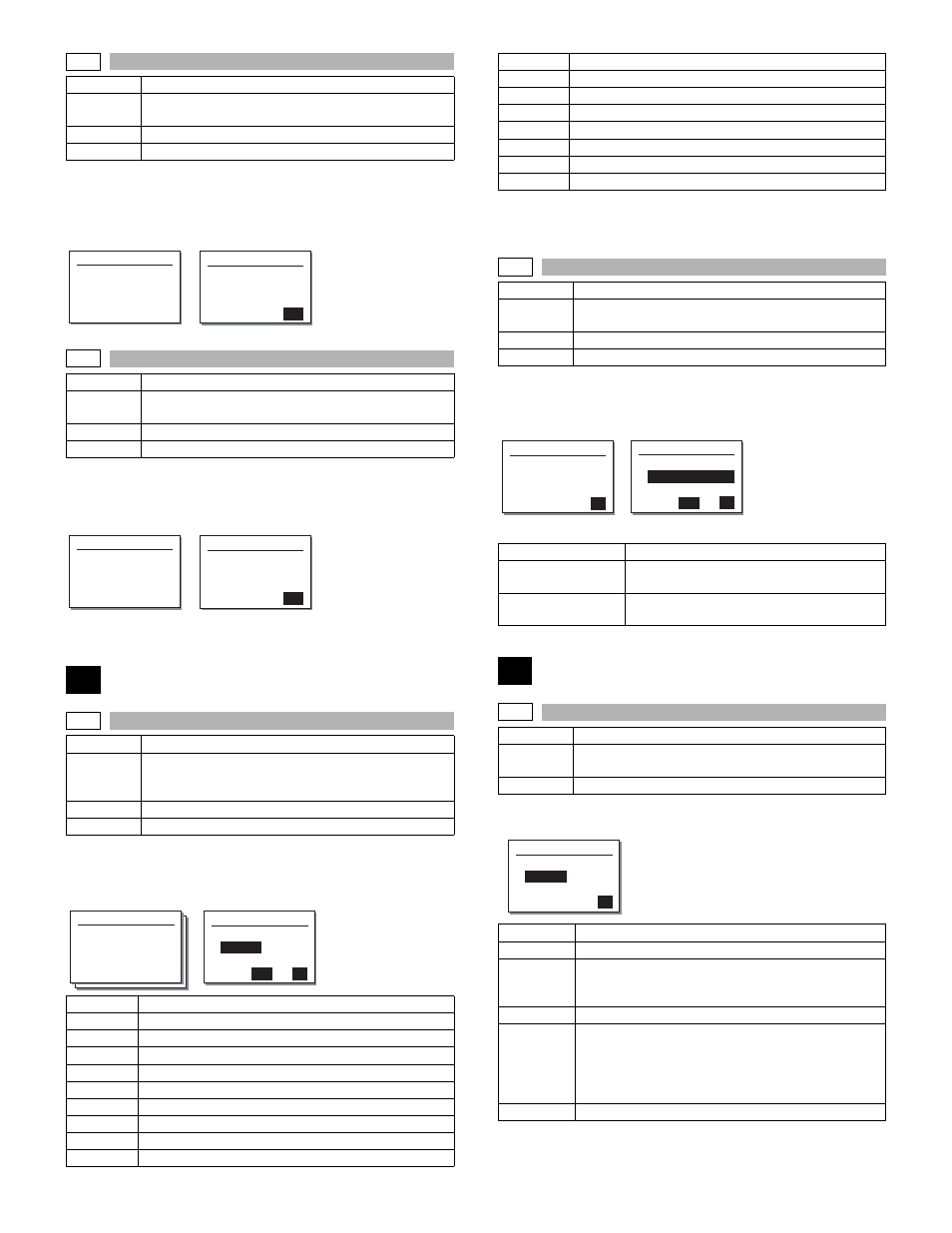

(Initial screen)

(Executing screen)

5-3

Purpose

Operation test/check

Function

(Purpose)

Used to check the operation of the copy lamp and the

control circuit.

Section

Optical (Image scanning)

Item

Operation

(Initial screen)

(Executing screen)

6

6-1

Purpose

Operation test/check

Function

(Purpose)

Used to check the operation of the loads (clutches and

solenoids) in the paper transport system and the

control circuit.

Section

Paper transport (Discharge/Switchback/Transport)

Item

Operation

(Initial screen)

(Executing screen)

1:LUM1

1st cassette lift-up motor

2:CPFC1

1st cassette pick-up solenoid

3:CPFS1

1st cassette paper feed clutch

4:MPFS

Manual feed pick-up solenoid

5:RRC

Resist roller clutch

6:PSPS

Separation pawl solenoid

7:OGS

Paper exit gate switching solenoid

8:LUM2

2nd cassette lift-up motor

9:CPFC2

2nd cassette pick-up solenoid

10:CPFS2

2nd cassette paper feed clutch

Sim5-2 HEATER LAMP

PRESS OK KEY EXEC

Sim5-2 HEATER LAMP

EXEC

Sim5-3 COPY LAMP

PRESS OK KEY EXEC

Sim5-3 COPY LAMP

EXEC

Sim6-1 OUTPUT CHECK

1:LUM1 4:MPFS

2:CPFC1 5:RRC

3:CPFS1 6:PSPS

1/2 EXEC

Sim6-1 OUTPUT CHECK

7:OGS 10:CPFS2

8:

LUM2

11:TRC2

9:CPFC2

2/2

EXEC

8

11:TRC2

2nd cassette transport roller clutch

12:LUM3

3rd cassette lift-up motor

13:CPFC3

3rd cassette pick-up solenoid

14:CPFS3

3rd cassette paper feed clutch

15:TRC3

3rd cassette transport roller clutch

16:LUM4

4th cassette lift-up motor

17:CPFC4

4th cassette pick-up solenoid

18:CPFS4

4th cassette paper feed clutch

6-2

Purpose

Operation test/check

Function

(Purpose)

Used to check the operation of each fan motor and its

control circuit.

Section

Others

Item

Operation

(Initial screen)

(Executing screen)

1:VFM

Only the fusing fan operates

2:DCFM&DCFM2

Power cooling fan, power cooling fan 2

operations

3:VFM&DCFM&DCFM2

Fusing fan, power cooling fan, and power

cooling fan 2 are operated at the same time.

7

7-1

Purpose

Setting/Operation test/check

Function

(Purpose)

Used to set the aging operation conditions.

Item

Operation

1:AGING

Aging enable/disable setting

2:MISFEED

Jam detection enable/disable setting

3:FUSING

Fusing operation enable/disable setting

The fusing temperature is not controlled. The heater is

not turned ON.

4:INTERVL

Intermittent setting (Valid only when set to AGING.)

5:WARMUP

Warm-up save setting

The machine goes into the ready state only by

shading, disregarding fusing and process control.

After going into the ready state, normal control is

performed.

6:DV CHK.

Developing unit detection enable/disable setting

Sim6-2 FAN MOTOR

1:VFM

2:DCFM&DCFM2

3:VFM&DCFM&DCFM2

EXEC

2

Sim6-2 FAN MOTOR

1:VFM

2:

DCFM

&DCFM2

3:VFM&DCFM&DCFM2

EXEC

2

Sim7-1 AGING SET.

1:AGING 4:INTERVL

2:

MISFEED

5:WARMUP

3:FUSING 6:DV CHK.

2