Sharp Digital Laser Copier/Printer AR-5127 User Manual

Page 22

AR-5127 ADJUSTMENTS 7 - 3

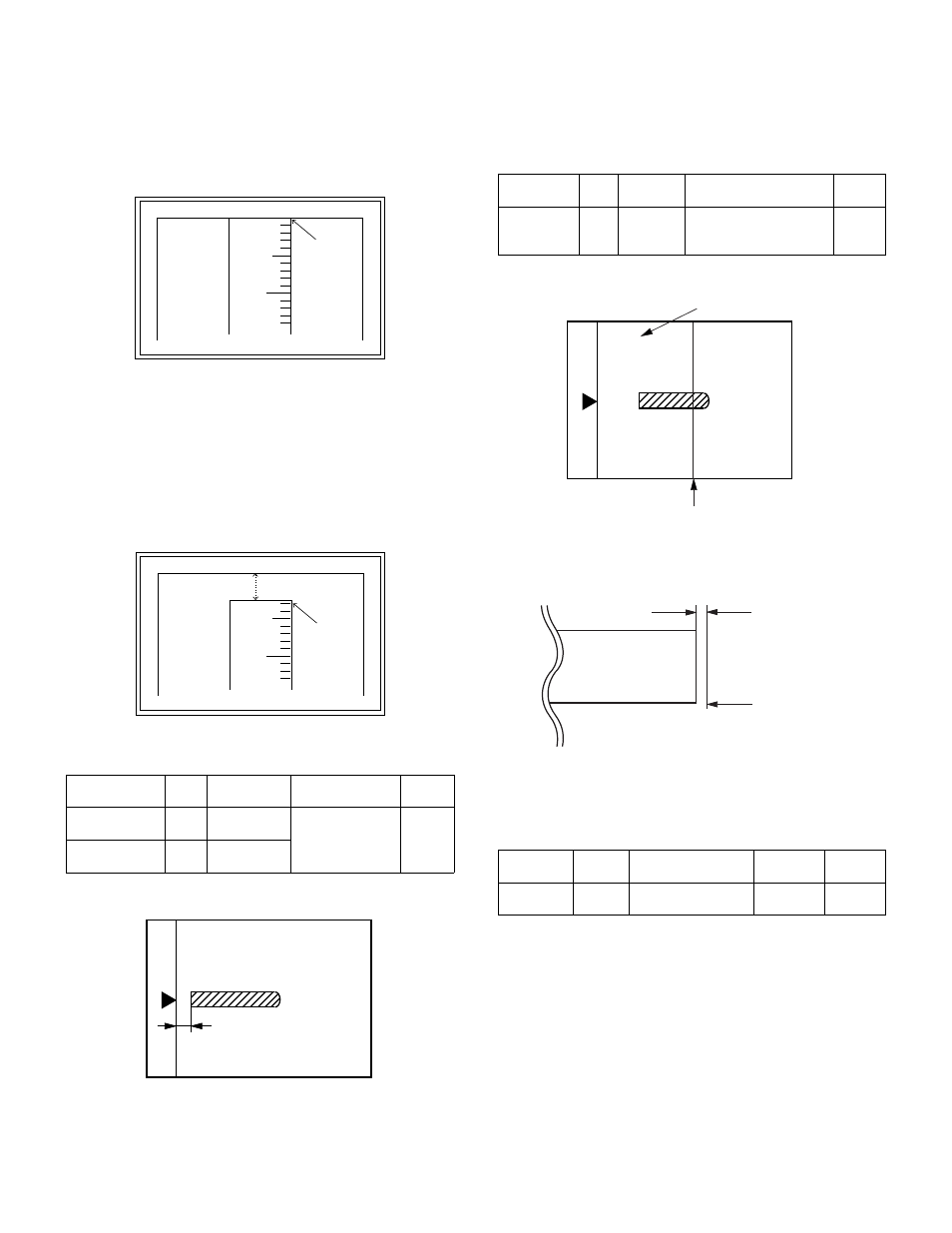

Setup of various copy conditions: Similar to the normal copy mode.

2) Measure the distance H between the paper lead edge and the

image print start position. Set the image print start position set

value again.

• 1 step of the set value corresponds to about 0.127mm shift.

• Calculate the set value from the formula below.

99 – H/0.127 (mm) = Image print start position set value

∗

Fit the print edge with the paper edge, and perform the lead

edge adjustment.

Example: 99 – 5/0.127 = 99 – 39.4 = about 59

Note: If the set value is not obtained from the above formula, per-

form the fine adjustment.

3) Execute SIM 50-1-2 to adjust the main cassette lead edge void.

• 1 step of the set value corresponds to about 0.127mm shift.

• Calculate the set value from the formula below.

B/0.127 (mm) = Lead edge void adjustment value

Example: When setting the lead edge void to 2.5mm:

2.5 /0.127 = about 20

(3) SPF image lead edge position adjustment

1) Set a scale on the OC table as shown below.

Note: Since the printed copy is used as a test chart, put the scale in

paralleled with the edge lines.

2) Make a copy, then use the copy output as an original to make an

SPF copy again.

3) Check the copy output. If necessary, perform the following adjust-

ment procedures.

4) Execute SIM 50-6.

5) Set the SPF lead edge position set value so that the same image is

obtained as that obtained in the previous OC image lead edge

position adjustment.

(4) Rear edge void adjustment

1) Set a scale as shown in the figure below.

2) Set the document size to A4 (8.5" x 11"), and make a copy at

100%.

3) If an adjustment is required, follow the procedures below.

4) Execute SIM 50-1 and set the density mode to DEN-B. The cur-

rently set adjustment value is displayed.

5) Enter the set value and press the start key.

The correction value is stored and a copy is made.

(5) Paper off center adjustment

1) Perform this adjustment after execution of SIM 48-3.

2) Set a test chart (UKOG-0089CSZZ) on the document table.

3) Select a paper feed port and make a copy.

Compare the copy and the test chart. If necessary, perform the follow-

ing adjustment procedure.

4) Execute SIM 50-10.

Select the mode with the arrow keys, enter the adjustment value

with the 10-key, and press the [OK] key.

Pressing the [START] key makes a print.

Pressing the [RETURN] key returns to the mode selection.

Adjustment

mode

SIM

Set value

Spec value

Setting

range

Main cassette

lead edge void

50-1-

2

B/0.127

Lead edge void:

1 to 4mm

Image loss: 3mm

or less

1 – 99

Print start

position

50-5

99 – H/0.127

5

10

0mm

0mm

5

10

2.5mm

2.5mm

Adjustment

mode

SIM

Set value

Spec value

Setting

range

SPF image

lead edge

position

50-6 1 step:

0.127mm

shift

Lead edge void:

1 – 4mm

Image loss: 3mm or less

1 – 99

Adjustment

mode

SIM

Set value

Spec

value

Setting

range

Rear edge

void

50-1-6

1 step: 0.127mm

shift

4mm or

less

1 – 99

A4 (8.5" x 11")

Paper rear edge

Void amount (Standard value: 4mm or less)

Scale image

Paper rear edge