Protective functions – MITSUBISHI ELECTRIC FR-A500L User Manual

Page 47

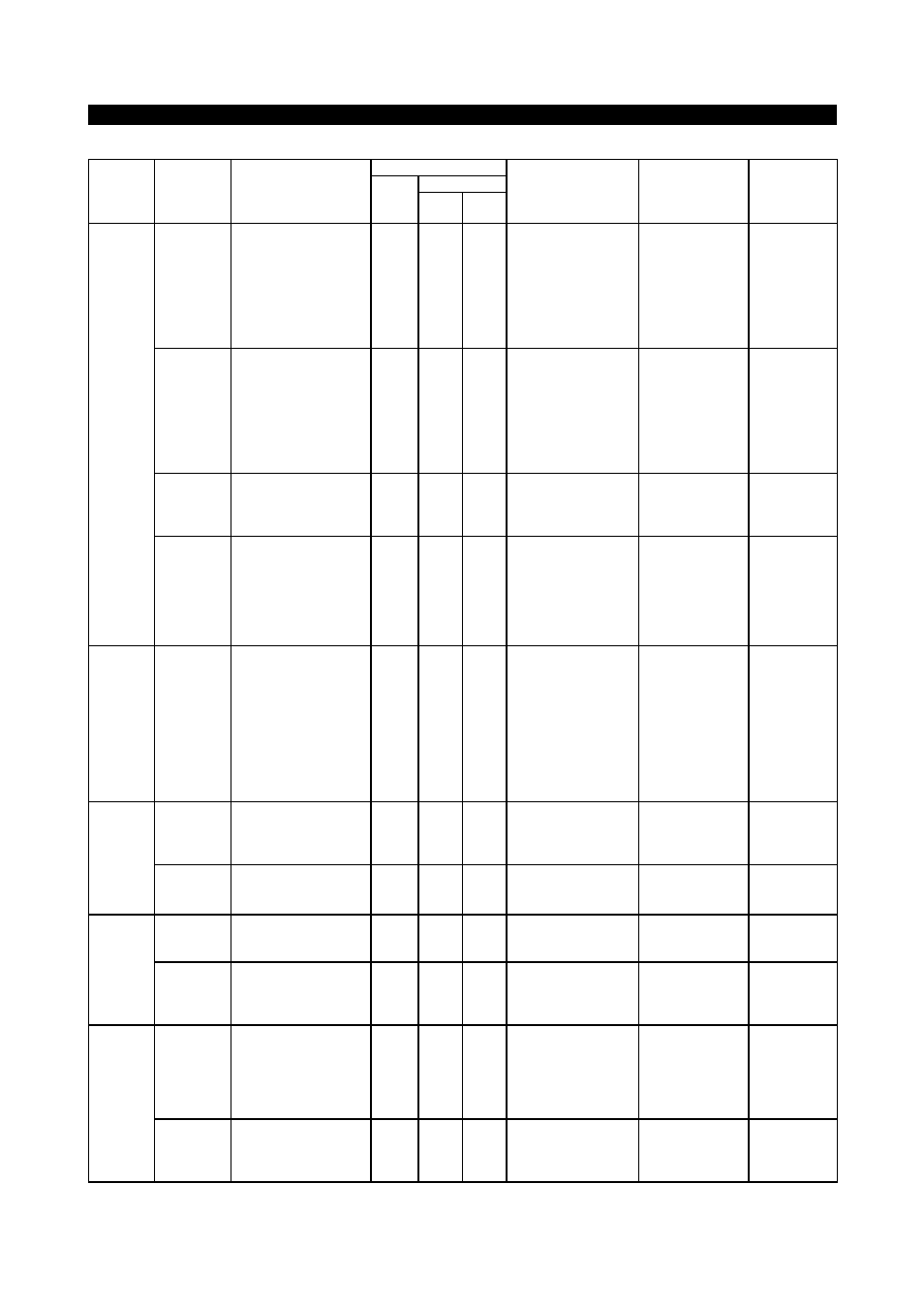

PROTECTIVE FUNCTIONS

36

Daily and Periodic Inspection

Interval

Periodic

Area of

Inspec-

tion

Inspection

Item

Description

Daily

1

year

2

years

Method

Criterion

Instrument

Inverter

module,

Converter

module

Check resistance

across terminals.

{

Disconnect cables 1 , L 2 , L 3, +, -, and U, V, W, +, -> with tester Ω . (See the following Analog tester Smoothing (1) Check for liquid leakage. (2) Check for safety valve projection and (3) Measure electrostatic { { { (1), (2) Visual check. capacity meter. (1), (2) No fault. Capacity Relay (1) Check for chatter during operation. (2) Check for rough surface on contacts. { { (1) Auditory check. (1) No fault. Main Resistor (1) Check for crack in resistor insulation. (2) Check for open cable. { { (1) Visual check. Cement resistor, (2) Disconnect one end and measure (1) No fault. be within ± 10% of indicated Tester, digital Control Operation (1) Check balance of output voltages (2) Perform sequence protective operation { { (1) Measure voltage across inverter (2) Simulatively connect or (1) Phase-to- phase voltage (2) Fault must occur because Digital Cooling fan (1) Check for unusual vibration and noise. (2) Check for loose connection. { { (1) Turn by hand with power off. (2) Re-tighten (1) Smooth rotation. (2) No fault. Cooling Cooling fan Is the power supply's { Measure with a tester. 24V 2.4V Tester Display (1) Check if LED lamp is blown. (2) Clean. { { (1) Light indicator lamps on panel. (2) Clean with rag. (1) Check that lamps are lit. Display Meter Check that reading is { Check reading of Must satisfy Voltmeter, General (1) Check for unusual vibration and noise. (2) Check for unusual odor. { { (1) Auditory, sensory, visual checks. (2) Check for unusual odor due to (1), (2) No fault. Motor Insulation (1) Check with megger (across terminals { (1) Disconnect cables from U, V, W, (1) 5M Ω or more 500V megger

from inverter and

measure across

terminals R, S, T, P, N

and U, V, W, P, N

range of 100

pages)

capacitor

bulge.

capacity.

(3) Measure with

(3) 85% or more

of rated capacity.

meter

(2) Visual check.

(2) No fault.

circuit

wire-wound

resistor.

with tester.

(2) Error should

resistance

value.

multimeter

circuit

Protective

circuit

check

across phases with

inverter operated

independently.

test to make sure of

no fault in protective

and display circuits.

output terminals

U-V-W.

disconnect inverter

protective circuit

output terminals.

balance within

8V for 400V.

of sequence.

multimeter,

rectifier type

voltmeter

system

power

supply

output voltage correct?

normal.

meters on panel.

specified and

management

values.

ammeter, etc.

overheating,

damage, etc.

resistance

and ground

terminal).

including motor

cables.