2 wiring, 1 terminal connection diagram, Installation and wiring – MITSUBISHI ELECTRIC FR-A500L User Manual

Page 13

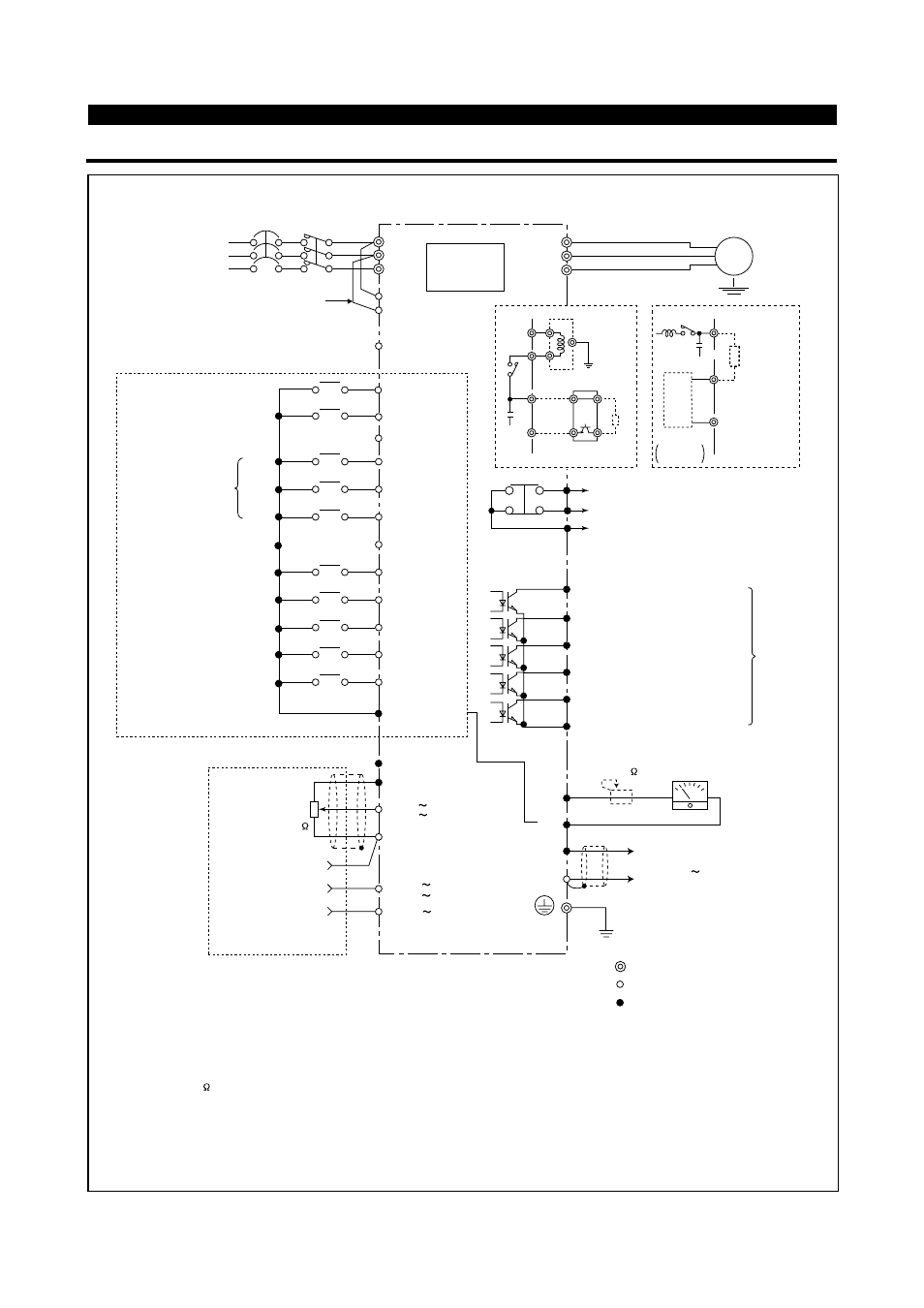

2.2 Wiring

INSTALLATION AND WIRING

5

2.2.1 Terminal connection diagram

Control circuit input terminal

Main circuit terminal

Control circuit output terminal

3-phase AC power supply

24VDC power output and extemal transistor common

(Contact input common for source logic)

Reverse rotation start

Forward rotation start

Jumper

NFB

MC

High

Start self-holding

selection

Multi-speed

selection

(Max. 15 speeds)

Middle

Low

Jog mode

Second acceleration/

deceleration time selection

Output stop

Reset

Current input selection

10E(+10V)

CS

AU

MRS

RES

RT

RL

JOG

RM

RH

STR

STF

PC

S1

T

R1

S

R

W

V

U

10(+5V)

2(

Selected)

4(DC 4 20mA)

Control input signals(no voltage input allowed)

Frequency setting

potentiometer

1/2W1k

Common

Auxiliary input

Current input

Inverter

FR-A500L

STOP

(Note 6)

(Note 8)

(Note 1)

(Note 4)

(Note 7)

(Note 8)

(Note 1)

(Note 9)

(Note 6)

(Note 1)

(Note 2)

Frequency setting signals (analog)

Ground

Ground

(+)

+

-

(-)

AM

Analog signal output

(DC0 10V)

Frequency detection

Instantaneous power failure

Open collector

outputs

Overload

Up to frequency

Running

Open collector output common

Common to sink and source

Moving-coil type

1mA full-scale

DC0 5V

DC0 10V

5(Analog common)

SD( )

Contact imput

common

10(

Selected)

DC0 5V

DC0 10V

PU

connector

(RS-485)

IM

(

)

(

)

SD

FM

RUN

A

B

C

SU

OL

IPF

FU

SE

Meter

(e.q.frequency meter)

calibration resistor

1/2W10k

Error output

(contact output)

(1) This connection diagram shows the example for the sink logic (factory-

set) control circuit. When using the source logic, refer to page 14 for the

connections.

(2) Use of the 2W1k is recommended when the frequency setting is

changed frequently.

(3) Always connect the enclosed DCL at P1, P. (375,450K)

DCL is prewired in the panel. P1 terminal is not prepared as terminals.

(530-900K)

(4) The output terminal can output the error alarm code, and 26 types of

functions can be independently assigned with Pr. 190 to 195.

(5) The input signal can be changed over with Pr.73.

(6) This is not required when the scale is calibrated with the operation

panel.

(7) Always ground the inverter unit, DCL and motor.

(8) JOG is assigned. (375-900K)

Notes

Selection of automatic restart

after instantaneous power

failure

Motor

+-

+-

Brake unit

option

530K-800K

P(+)

P

72

+

E

DCL

P1

Brake

resistor

(option)

PR

+

P

DCL

375K, 450K

530K-800K

N

Inside

Panel

Option

(Outside

Panel

Option)

Brake

Resistor

(See Page 49)