Installation and wiring, 1) description of main circuit terminals, 2) description of control circuit terminals – MITSUBISHI ELECTRIC FR-A500L User Manual

Page 14

INSTALLATION AND WIRING

6

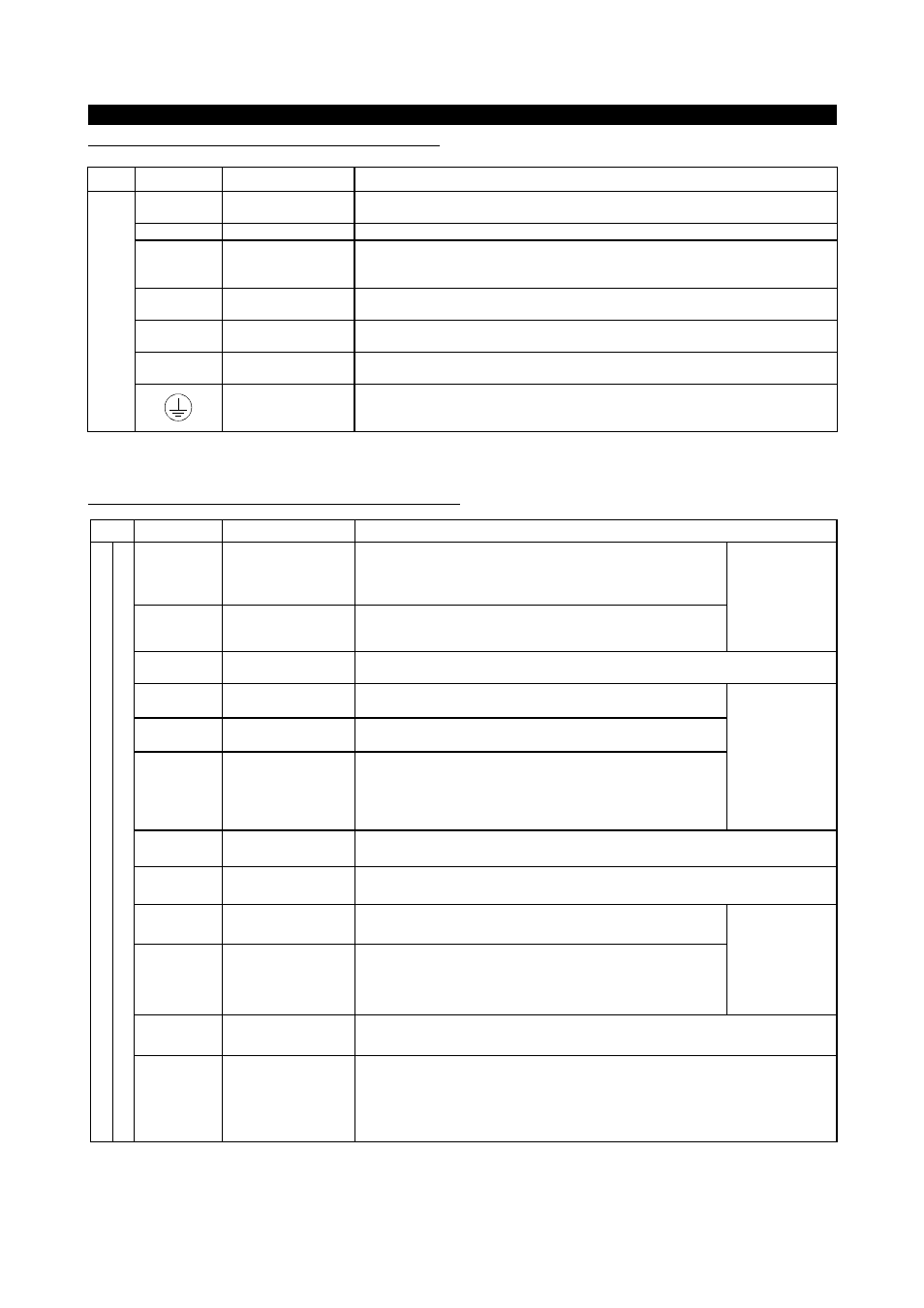

(1) Description of main circuit terminals

Type

Symbol

Terminal Name

Description

R, S, T

1 , L 2 , L 3 > AC power input Connect to the commercial power supply. Keep these terminals unconnected when U, V, W Inverter output Connect a three-phase squirrel-cage motor. R1, S1 11 , L 21 > Power supply for Connected to the AC power supply terminals R and S. To retain the alarm display P, N <+,-> Optional converter Connect the optional power return converter (MT-RC) or high power factor converter P, P1 DC reactor Connect the enclosed DC reactor. (375, 450K) P, PR <+, PR> Brake resistor Connect the optional FR-BR5 brake resistor. Main circuit Ground For grounding the inverter chassis. Must be earthed. Note:< >Terminal names in parentheses are those of the EC version. (2) Description of control circuit terminals Type Symbol Terminal Name Description STF Forward rotation start Turn on the STF signal to start forward rotation and turn it off to STR Reverse rotation start Turn on the STR signal to start reverse rotation and turn it off to When the STF STOP Start self-holding Turn on the STOP signal to select the self-holding of the start signal. RH RM RL Multi-speed selection Use the RH, RM and RL signals as appropriate to select multiple (JOG) JOG mode selection This terminal connected internally, can not be used by the RT Second acceleration/ Turn on the RT signal to select the second acceleration/ Input terminal MRS Output stop Turn on the MRS signal (20ms or longer) to stop the inverter output. RES Reset Used to reset the protective circuit activated. Turn on the RES signal for more than 0.1 AU Current input Only when the AU signal is turned on, the inverter can be CS Automatic restart after With the CS signal on, restart can be made automatically when Input terminal SD Contact input Common terminal for the terminal FM. Input s ignal s Cont ac ts , e. g. s tart , f unc tion s et tin g PC 24VDC power and When transistor output (open collector output), such as a programmable controller, is

using the high power factor converter (MT-HC).

control circuit

and alarm output or when using the high power factor converter (MT-HC), remove the

jumpers from terminals R-R1 and S-S1 and apply external power to these terminals.

connection

(MT-HC).

connection

DC reactor is prewired in 530-800K sizes.

connection

stop. Acts as a programmed operation start signal in the

programmed operation mode. (Turn on to start and turn off to

stop.)

stop.

and STR signals

are turned on

simultaneously,

the stop

command is

given.

selection

speeds.

customer. (530-800K:this signal is assigned in Factory.)

deceleration time

selection

deceleration time. When the second functions such as "second

torque boost" and "second V/F (base frequency)" functions have

been set, these functions can also be selected by turning on the

RT signal.

function selection

(Pr. 180 to

Pr. 186) change

terminal functions.

Used to shut off the inverter output to bring the motor to a stop by the magnetic brake.

sec, then turn it off.

selection

operated with the 4-20mADC frequency setting signal.

instantaneous power

failure selection

the power is restored after an instantaneous power failure. Note

that this operation requires restart parameters to be set. When the

inverter is shipped from the factory, it is set to disallow restart.

function selection

(Pr. 180 to Pr.

186) change

terminal functions.

common (sink)

Common output terminal for 24VDC 0.1A power (PC terminal).

external transistor

common

Contact input

common (source)

connected, connect the external power supply common for transistor output to this

terminal to prevent a fault caused by leakage current. This terminal can be used as a

24VDC, 0.1A power output. When source logic has been selected, this terminal

serves as a contact input common.