12 pid control – MITSUBISHI ELECTRIC 700 Series User Manual

Page 46

41

PID control

1

1.12 PID control

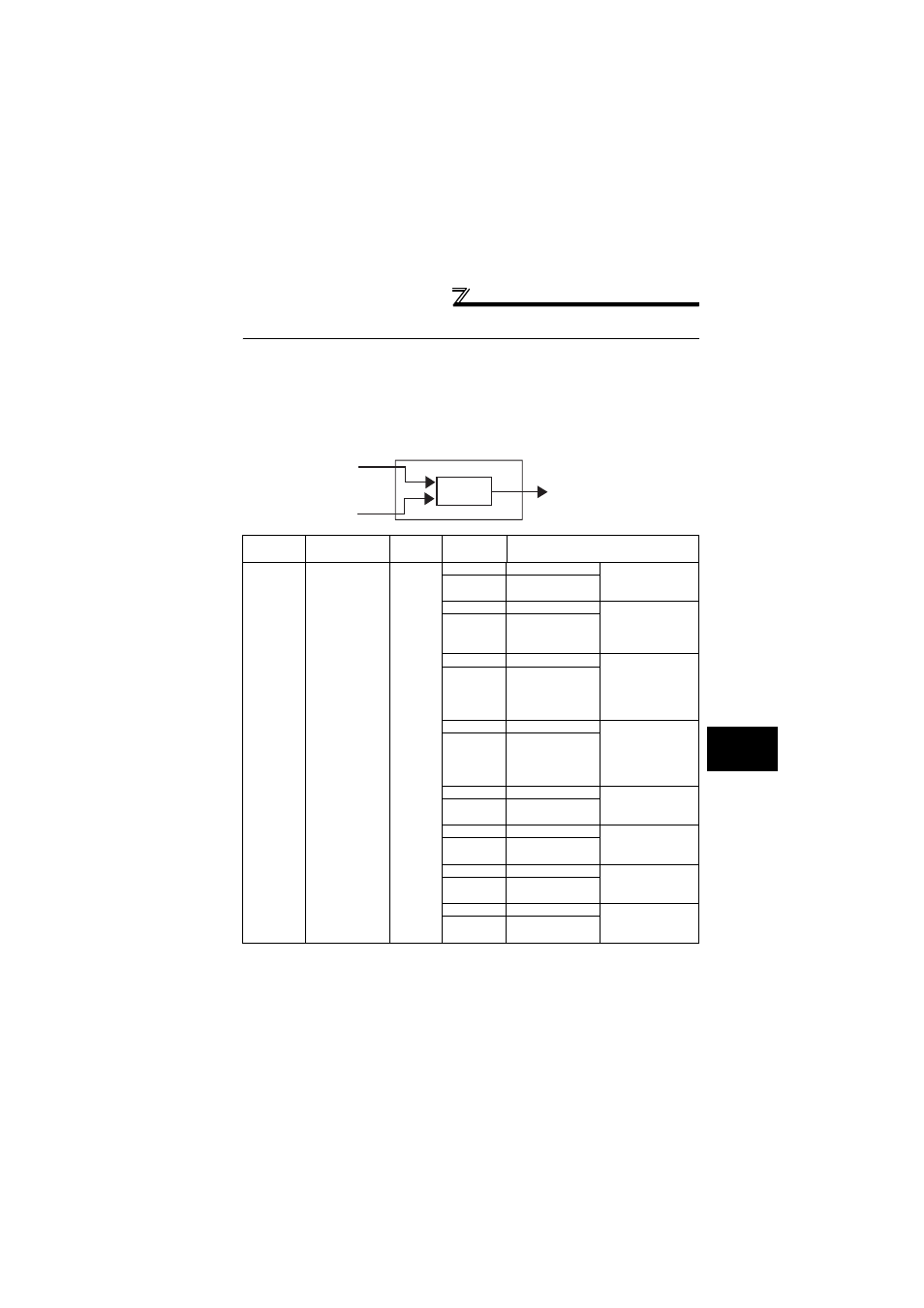

With PLC function, PID set point/PID deviation value, PID process value can be set by

setting Pr. 128.

Performing the PID operation using the value of D9248 and D9249 as PID set point/

PID deviation value, PID process value, manipulated variable is stored to D9250.

When performing PID control with PLC function, "1" is set on D9255 instead of X14

signal.

Parameter

Name

Initial

Value

Setting

Range

Description

128

PID action

selection

10

10

PID reverse action

Deviation value

signal input

(terminal 1)

11

PID forward action

20

PID reverse action

Measured value

(terminal 4)

Set point (terminal

2 or Pr. 133)

21

PID forward action

50

PID reverse action

Deviation value

signal input

(L

ON

W

ORKS

,

CC-Link

communication)

51

PID forward action

60

PID reverse action

Measured value,

set point input

(L

ON

W

ORKS

,

CC-Link

communication)

61

PID forward action

70

PID reverse action

Deviation value

signal input

(PLC function)

71

PID forward action

80

PID reverse action

Measured value,

Set point

(PLC function)

81

PID forward action

90

PID reverse action

Deviation value

signal input

(PLC function)

91

PID forward action

100

PID reverse action

Measured value,

Set point input

(PLC function)

101

PID forward action

D9248

D9249

PID set point /

PID deviation

PID manipulated variable D9250

or

Inverter frequency setting

PID measurement

value

PID control