22 operation error – MITSUBISHI ELECTRIC 700 Series User Manual

Page 107

102

Operation Error

3.22 Operation Error

When a basic instruction is used, an operation error will occur in the following

case.

(a) If any error described in the description of the corresponding instruction

occurs.

(1) Error processing

If an operation error occurred at execution of a basic instruction, the error flag

turns on and the error step number is stored into the error step storage register.

1) D9011 stores the step number of the instruction where an operation error occurred

when M9011 turned from OFF to ON. Therefore, D9011 data does not change if

M9011 remains on.

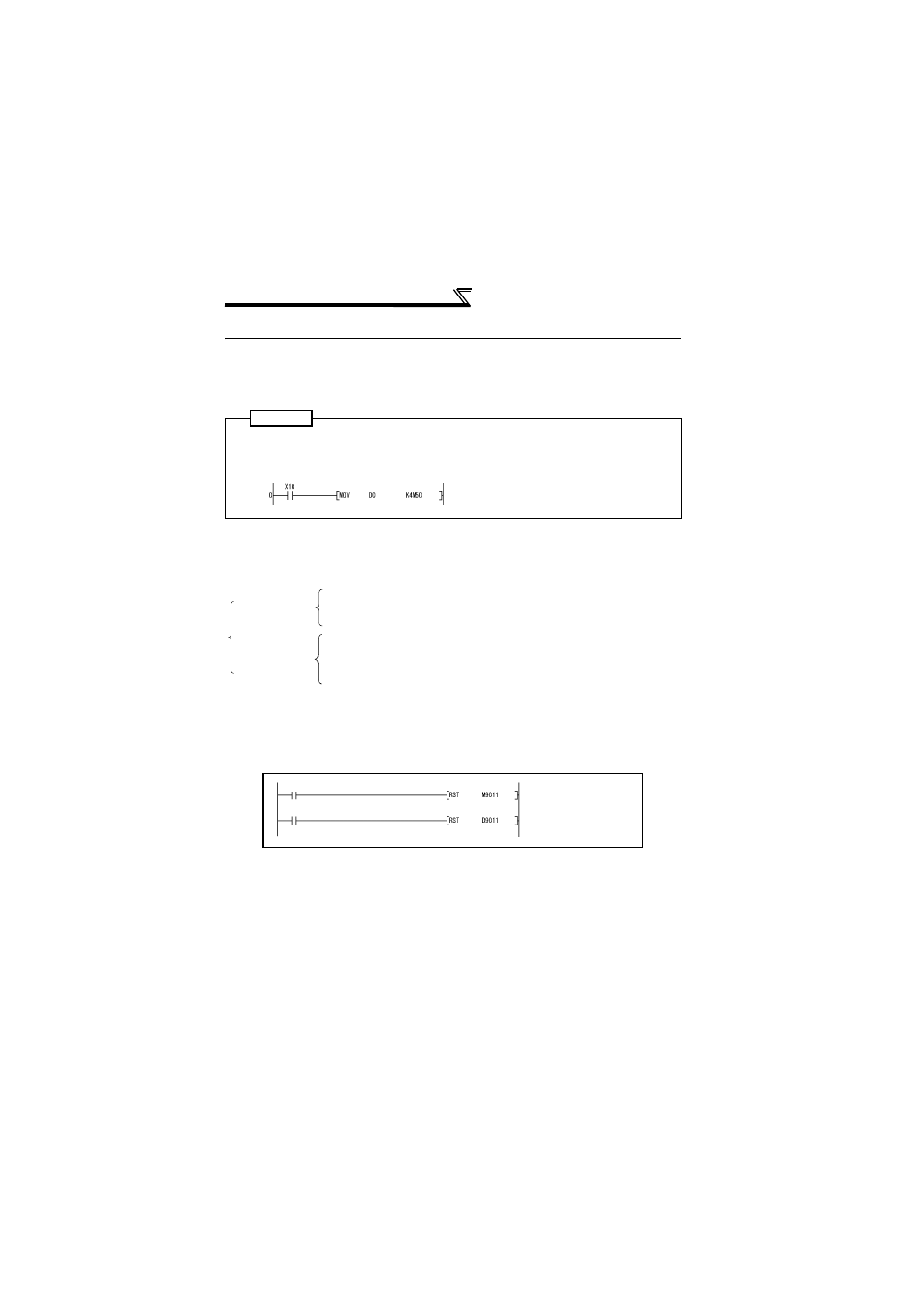

2) To reset M9011 and D9011, program as shown below.

Fig 3.28 Special Relay and Register Resetting Ladder

3) Whether sequence processing will be stopped or continued at occurrence of an

operation error can be selected by built-in PLC function parameter setting. Refer to

page 94 for details.

POINT

Note that if the device designation range is outside the corresponding device

range, an operation error does not occur and data is written to other than the

specified device.

Error flag

M9010 ... Turns on at an operation error and turns off if the next basic

instruction is normal.

M9011.... Turns on at the first operation error.

Error step

storage register

D9010.... Stores the first step number of the instruction where an operation

error occurred.

D9011 .... Stores the first step number of the instruction where an operation

error occurred first.

M50 to M65 are the targets, but actual

setting range is M0 to M63, and error

occurs since M64 and M65 do not exist.

Resets (turns off) M9011.

Resets D9011.

(Clears D9011 to 0.)

Reset command

Reset command