Tables – Grizzly G0564 User Manual

Page 30

-28-

Model g0563/g0564 (Mfg. since 10/11)

figure 30. oil fill hole and screw.

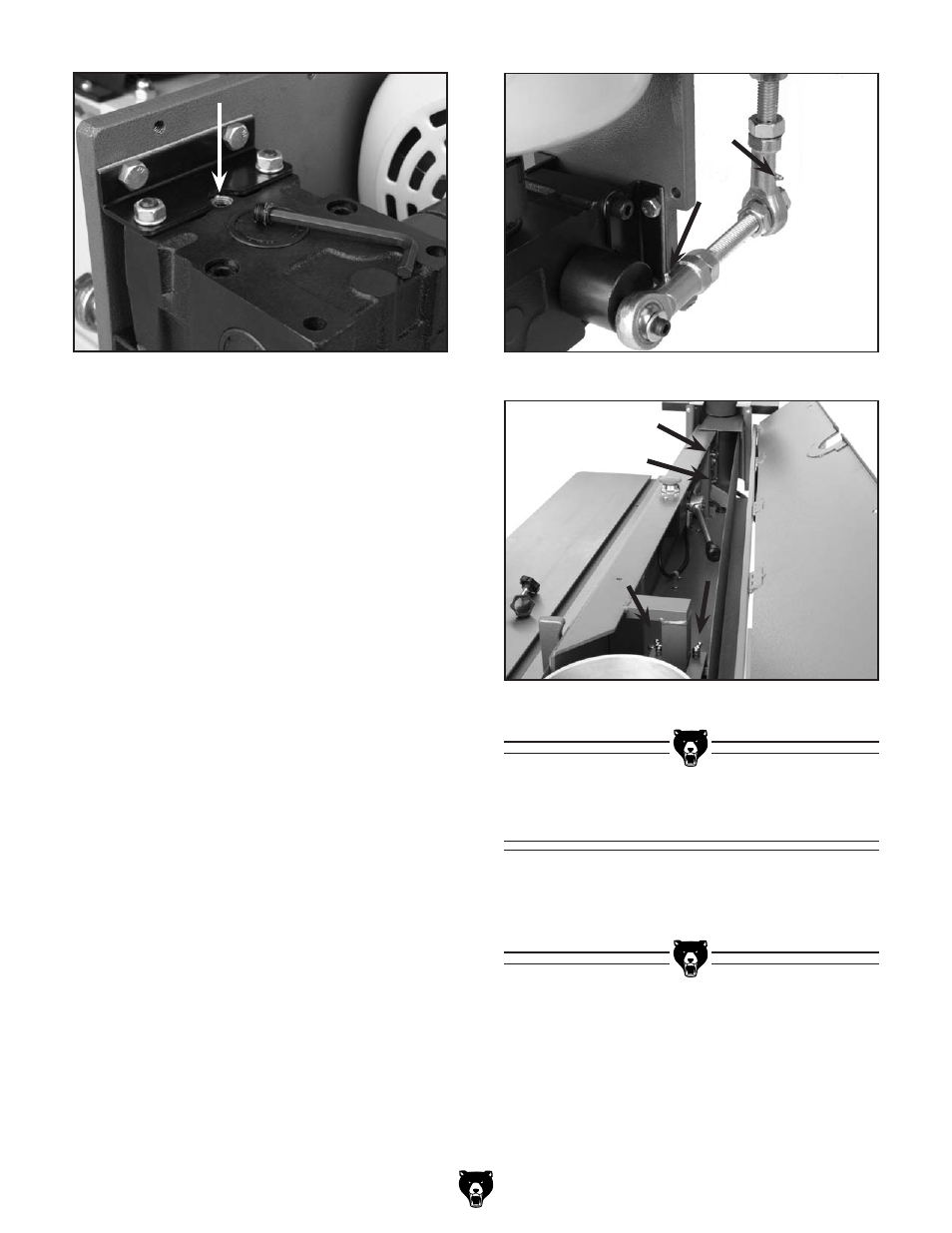

figure 31. oil ports on oscillating assembly.

5. reinstall the gear box cover with the hex

bolts and cap screws

rack and pinion Gear

the rack and pinion gear that moves the table

vertically should be greased well to maintain

smooth operation.

to grease the rack and pinion gear:

1. with the table in its lowest position, wipe

the rack and pinion with a rag to remove the

buildup of sawdust and old grease.

2. apply a coat of all purpose grease to the rack

and pinion gears.

Grease fittings & Oil ports

there are two oil ports shown in

figure 31 and

four grease fittings shown in

figure 32 on the

Model G0563/G0564. lubricate these points

after approximately 50 hours of use with a light

machine oil.

all other bearings on the Model g0563/g0564

are sealed and permanently lubricated and there

is no need to lubricate them.

figure 32. grease fittings inside sanding body.

the tables of the model g0563/g0564 can be

kept rust-free with regular applications of prod-

ucts like Boeshield t-9

®

or slipit

®.

tables