Motor & electrical, Operations – Grizzly 50/65 Ton Ironworker G0646 User Manual

Page 46

-44-

G0646/G0647 50/65 Ton Ironworker

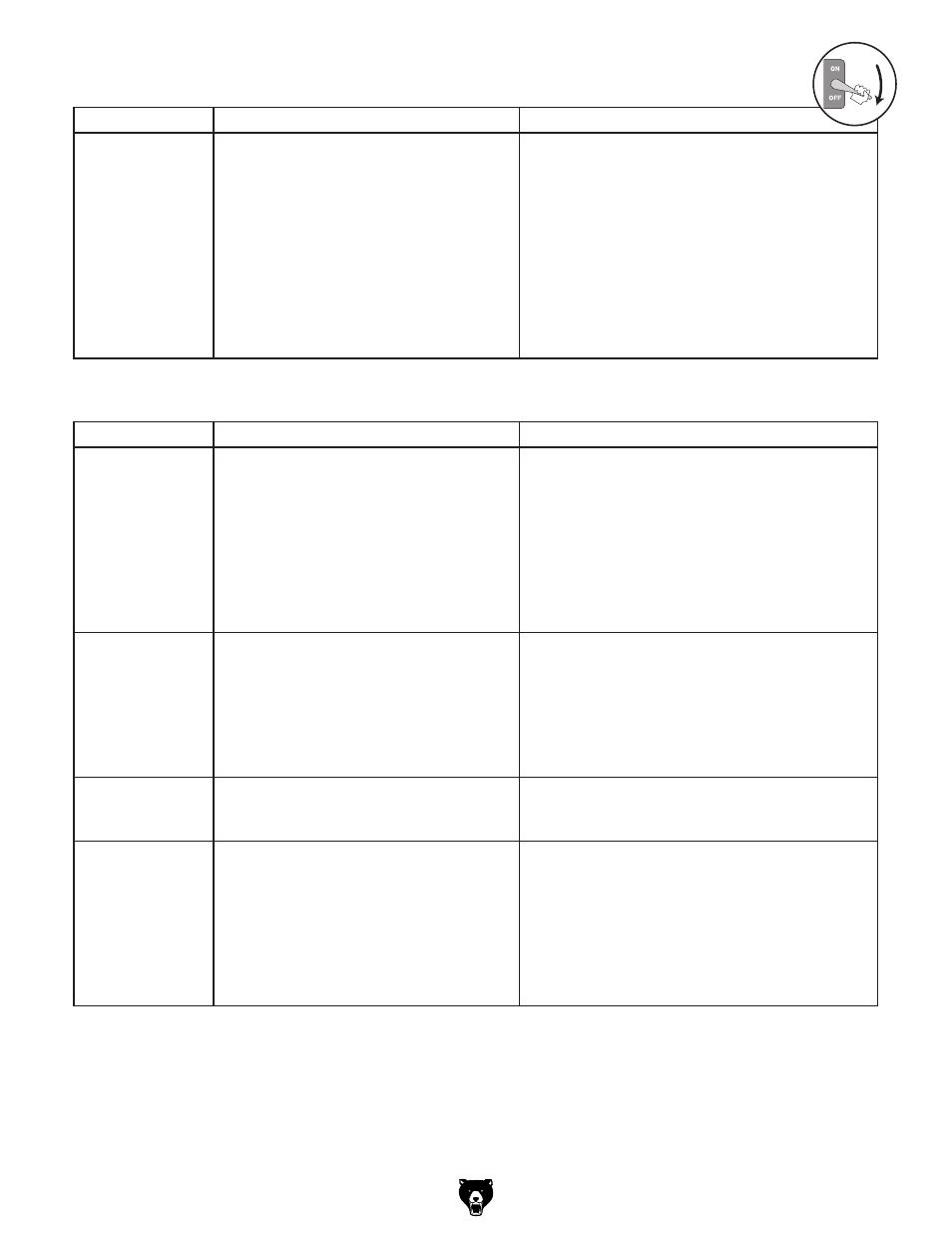

Motor & Electrical

Symptom

Possible Cause

Possible Solution

Machine has vibra-

tion or noisy opera-

tion.

1. Motor wired out of phase.

2. Motor or component is loose.

3. Motor mount loose/broken.

4. Machine is incorrectly mounted or sits

unevenly.

5. Motor fan is rubbing on fan cover.

6. Motor bearings are at fault.

1. Swap any to incoming power wires at the motor

(

Page 56).

2. Inspect/replace stripped or damaged bolts/nuts, and

re-tighten with thread locking fluid.

3. Tighten/replace.

4. Tighten/replace anchor studs in floor; relocate/shim

machine.

5. Replace dented fan cover; replace loose/damaged

fan.

6. Test by rotating shaft; rotational grinding/loose shaft

requires bearing replacement.

Operations

Symptom

Possible Cause

Possible Solution

Cuts are excessively

ragged or not accu-

rate.

1. Tooling damaged or dull.

2. Not using proper station.

3. Tooling not installed properly.

4. Cutting stroke not continuous through the

workpiece.

5. Workpiece moves away from tooling during

operation.

1. Check/sharpen/replace tooling.

2. Use the appropriate ironworker station for your

operation

3. Check/repair tooling installation and clearances.

4. Keep the Normal/Inch switch in

Normal position and

pressure on pedal actuator until workpiece is cut

completely through.

5. Use hold-downs, table guides, and other devices to

ensure workpiece is secure before cutting.

Tooling not cutting

completely through

workpiece.

1. Workpiece dimensions not within capacity

of machine.

2. Tooling is damaged or dull.

3. Hydraulic pump at fault.

4. Hydraulic system has leaks or valves at

fault.

1. Make sure workpiece dimensions are within machine/

station capacity; use cutting lubricant.

2. Check/sharpen/replace tooling.

3. Test/adjust correct hydraulic fluid pressure (

Page

50); replace pump if necessary.

4. Check/repair/replace hydraulic hoses, connections,

and valves.

Loud unusual noise

when beam revers-

es direction.

1. Limit stops not properly set.

1. Set limit rings and stops to factory settings (

Page

50).

Hydraulic fluid tem-

perature

at/over

160°F (70°C).

1. Machine cutting at/beyond capacity.

2. Hydraulic fluid pressure set to high.

3. Incorrect hydraulic fluid type.

4. Hydraulic system at fault.

1. Turn machine

OFF and allow hydraulic fluid to cool;

make cuts only with the capacity of your machine.

2. Reduce hyrdaulic fluid relief pressure to 3000 PSI

(

Page 50).

3. Use only one of recommended hydraulic fluids from

Figure 54

on

Page 40.

4. Have a qualified hydraulic service technician ser-

vice/repair the hydraulic system.