Beam lubrication – Grizzly 50/65 Ton Ironworker G0646 User Manual

Page 36

-34-

G0646/G0647 50/65 Ton Ironworker

3. Loosen the limit stop set screw, move the

limit stop along the limit bar, then re-tighten

the set screw.

Note: A small adjustment to the limit stop

position makes a large difference in the

stroke length. Make small adjustments, then

test the results.

4. Set the controls to Inch and in the desired

direction, reset the emergency stop button,

then turn the machine

ON.

5. Keep clear of the machine and use the pedal

actuator to test the adjustment.

Note: Be ready to immediately lift your foot

from the pedal actuator to stop the beam in

the case of a problem.

6. When you are satisfied with the adjustment

and results, re-install the limit stop assembly

access panel.

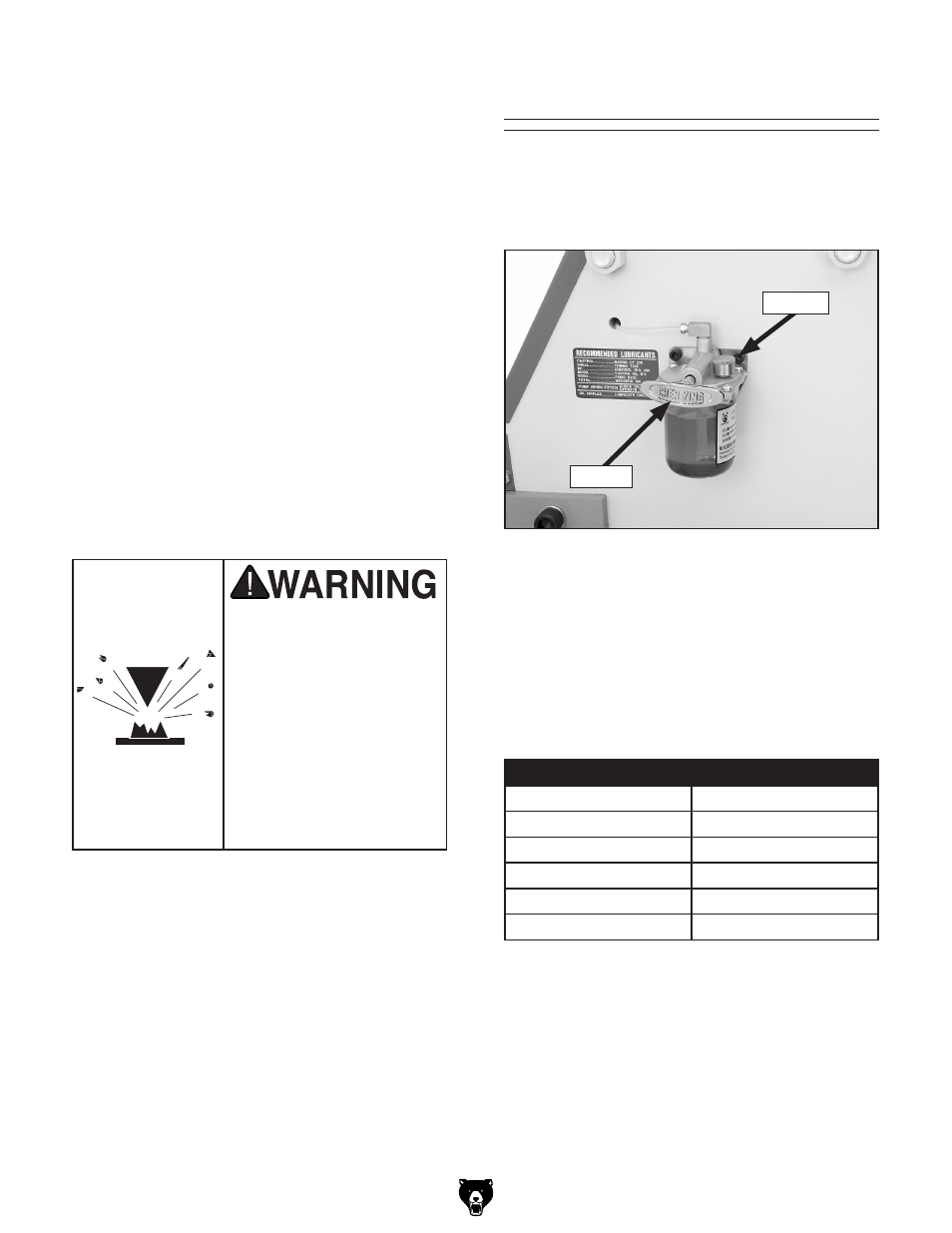

Beam Lubrication

To keep the beam movement smooth, use the

one-shot beam oiler (see

Figure 43) before

beginning operation and at least once every 4-

hours of operation.

Merely pull the handle of the oiler out, then let it

go. The oiler will force the lubricant through the oil

lines to points between the beam and the front/

rear panels that are subject to friction.

Fill the oiler with one of the lubricants from

Figure

44 or an equivalent.

Figure 43. One-shot beam oiler on the rear

panel.

Fill Cap

Handle

Brand

Type

B. P.

Energol GHL 220

Castrol

Magna CF 220

Esso

Febis K220

Mobil

Vactra Oil #4

Shell

Tomma T220

Total

Drosera 150

Figure 44. Recommended beam one-shot oiler

lubricants.

beam lubrication

Tooling and workpiece

could break apart under

pressure, sending metal

debris toward the opera-

tor at a high rate of speed.

Always keep all safety

guards and access panels

in the correct position and

secured when perform-

ing cutting operations

to reduce the risk of this

hazard.