Notching, Using the notching station, Removing & installing notch dies – Grizzly 50/65 Ton Ironworker G0646 User Manual

Page 27

G0646/G0647 50/65 Ton Ironworker

-25-

Notching

The notching station sets up to make notches of

varying sizes and shapes in flat bar mild steel

stock. The limit stops are adjustable to set the

most efficient stroke length for your operation

(refer to

Page 33).

Stay within the following notching capacities for

your machine:

Model G0646

Maximum Thickness ...........................

5

⁄

16

" (8mm)

Maximum Notch Width .................... 1

3

⁄

8

" (35mm)

Maximum Notch Depth ....................... 3" (75mm)

Model G0647

Maximum Thickness ..........................

3

⁄

8

" (10mm)

Maximum Notch Width .................... 1

5

⁄

8

" (42mm)

Maximum Notch Depth ..................... 4" (100mm)

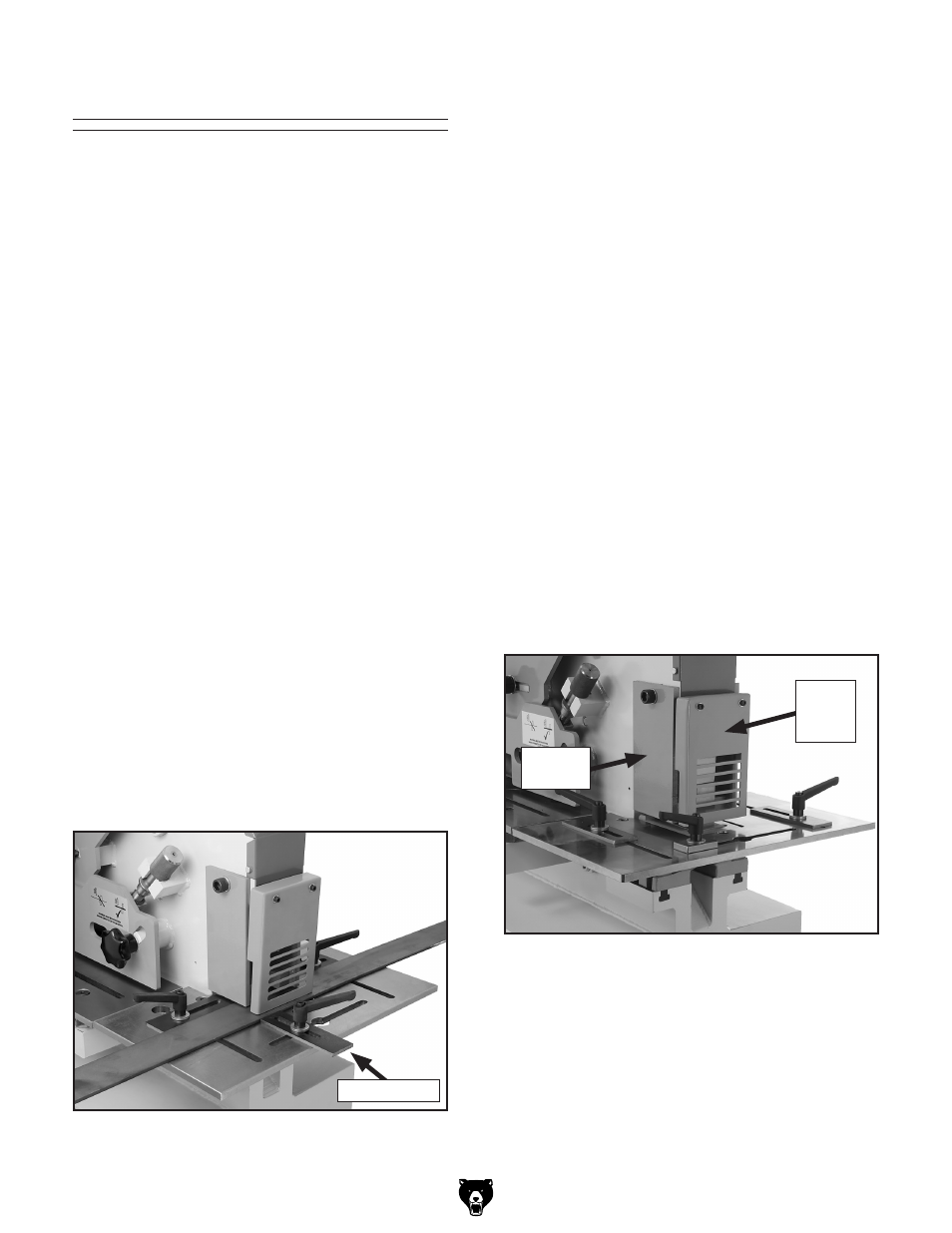

Using the Notching Station

1. Set the controls to Punch and Inch, then

raise the notching die so that you can insert

the workpiece.

2. Brush one of the lubricants from Figure 18 on

Page 22 or an equivalent onto both sides of

the workpiece.

3. Position the workpiece on the table and

under the tooling, then use the table guides

and other devices to support the workpiece

(see

Figure 24).

notching station tips

4. Set the controls to Notch and Normal, then

turn the motor

ON.

5. Stand clear of the machine and use the pedal

actuator to perform the notching operation.

Note: When the notching operation is com-

plete, the die will automatically raise up out

of the workpiece.

Removing & Installing Notch Dies

Tools Needed

Qty

Hex Wrenches 4, 5, 6, 8, 14mm ..............1 Each

Wrench 19mm ................................................... 1

Feeler Gauges 1mm, 3mm ......................1 Each

To remove the notch dies:

1. Set the controls to Punch and Inch, raise the

die to its uppermost position above the notch-

ing station, then turn the motor

OFF.

2. DISCONNECT MACHINE FROM POWER!

3. Remove the stripper plates from both sides

of the notching station and the front safety

guard (see

Figure 25).

Figure 25. Notching station stripper plate and

front safety guard.

Stripper

Plate

Front

Safety

Guard

Figure 24. Typical workpiece positioning for the

notching station.

Table Guide