Notice – Grizzly 50/65 Ton Ironworker G0646 User Manual

Page 25

G0646/G0647 50/65 Ton Ironworker

-23-

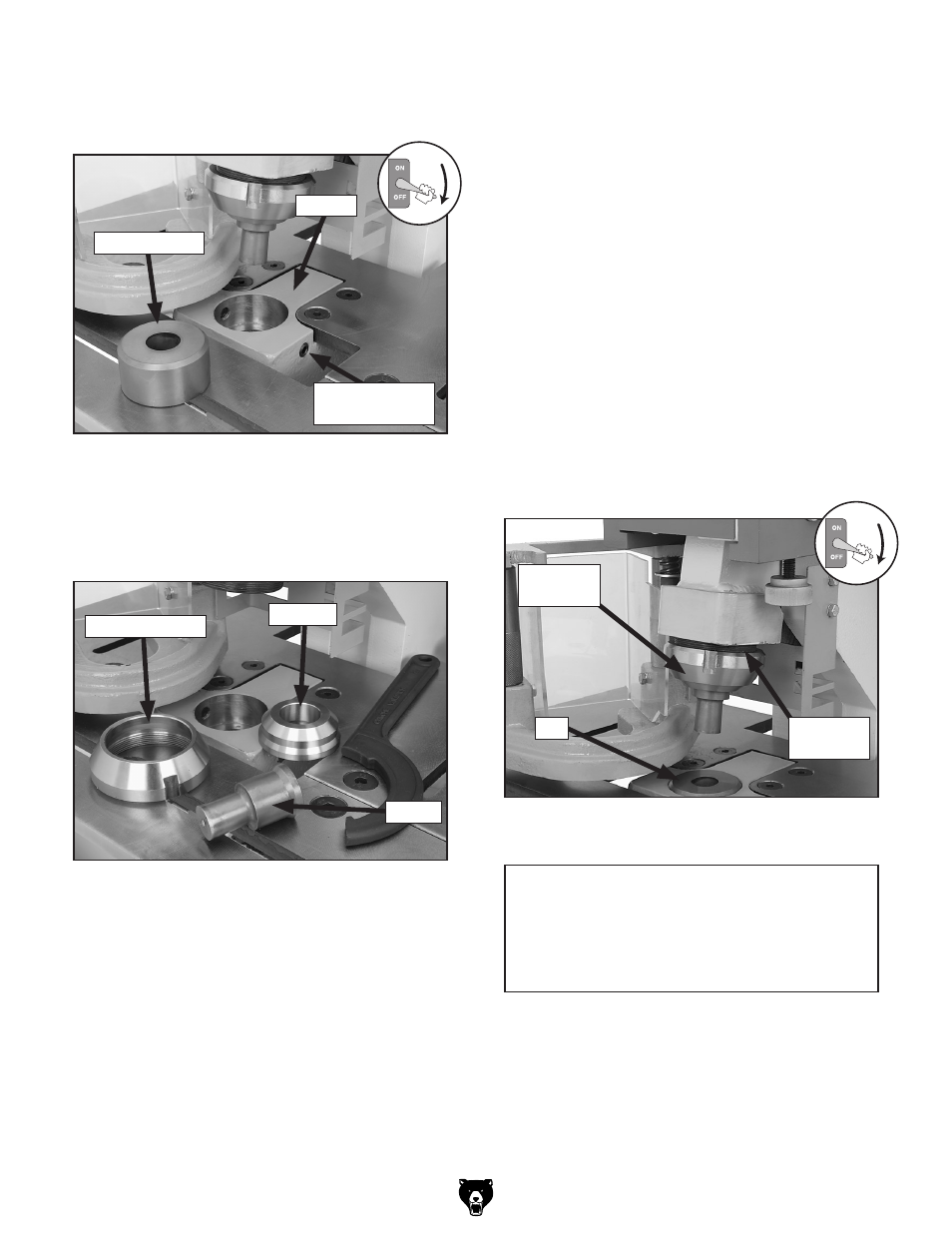

4. Loosen the die set screws on both sides of

the punch bolster, then lift the die from below

and remove it (see

Figure 20).

5. Use the spanner wrench to loosen and

remove the punch retaining ring, then sepa-

rate the punch adapter and die from the ring

(see

Figure 21).

Figure 21. Punch assembly removed and

separated.

Punch

Adapter

Retaining Ring

Figure 20. Punching die removed.

Punching Die

Set Screw

(1 of 2 shown)

Bolster

6. Thoroughly clean any metal debris or grime

off the punch, die, pressure plate, and bol-

ster.

Note: If you are storing the punch and

die, protect them with a light coat of an

anti-rust product like G96® Gun Treatment,

SLIPIT®, or Boeshield® T-9 (see

Section 5:

Accessories on Page 35 for more details).

To install punch tooling:

1. Set the controls to Notch and Inch, use the

foot actuator to raise the punch to the upper-

most position, then stop the motor.

2. DISCONNECT MACHINE FROM POWER!

3. Move the stripper and safety guard assembly

out of the way.

4. Thoroughly clean the punch, die, pressure

plate, and bolster, then re-lubricate them to

prevent rust.

5. Place the adapter into the retaining ring, then

the punch into the adapter (see

Figure 21).

6. Center the assembly up against the punch

pressure plate, then hand-tighten the retain-

ing ring to secure it in place (see

Figure 22).

Figure 22. Punch, adapter, retaining ring, and

die installed.

Die

Pressure

Plate

Punch

Assembly

NOTICE

To reduce the risk of tooling breakage, the

recommended side clearance between the

punch and die is approximately 10% of the

material thickness.