Flat stock shearing, Notice – Grizzly 50/65 Ton Ironworker G0646 User Manual

Page 30

-28-

G0646/G0647 50/65 Ton Ironworker

Flat Stock Shearing

The flat stock shearing station is designed to

straight or angle cut flat stock or cut one flange

of angle iron stock. Use the adjustable hold-down

and table guides for safe and accurate cuts.

Stay within the following flat stock shearing capac-

ities for your machine:

Model G0646

Maximum Thickness w/8" (200mm)

Workpiece Width ...............................

5

⁄

8

" (15mm)

Maximum Thickness w/12" (300mm)

Workpiece Width ...............................

1

⁄

2

" (12mm)

Maximum Thickness for Single Flange

Cut w/3" x 3" (80mm x 80mm)

Angle Iron ..........................................

3

⁄

8

" (10mm)

Model G0647

Maximum Shearing

Thickness w/8" (200mm)

Workpiece Width ...............................

3

⁄

4

" (20mm)

Maximum Shearing

Thickness w/12" (300mm)

Workpiece Width ...............................

5

⁄

8

" (15mm)

Maximum Thickness for Single Flange

Cut w/ 3" x 3" (80mm x 80mm)

Angle Iron ..........................................

3

⁄

8

" (10mm)

flat shearing tips

To avoid tooling or workpiece breakage and

the risk of possible injury to the operator,

never attempt to cut a workpiece that is not

adequately supported and held in place.

Never attempt a cutting operation that is

beyond the capacity of your machine.

NOTICE

To make accurate and safe flat stock cuts,

be sure the table and bottom shearing die

are level and even with each other (refer to

Shearing Table Alignment on Page 49).

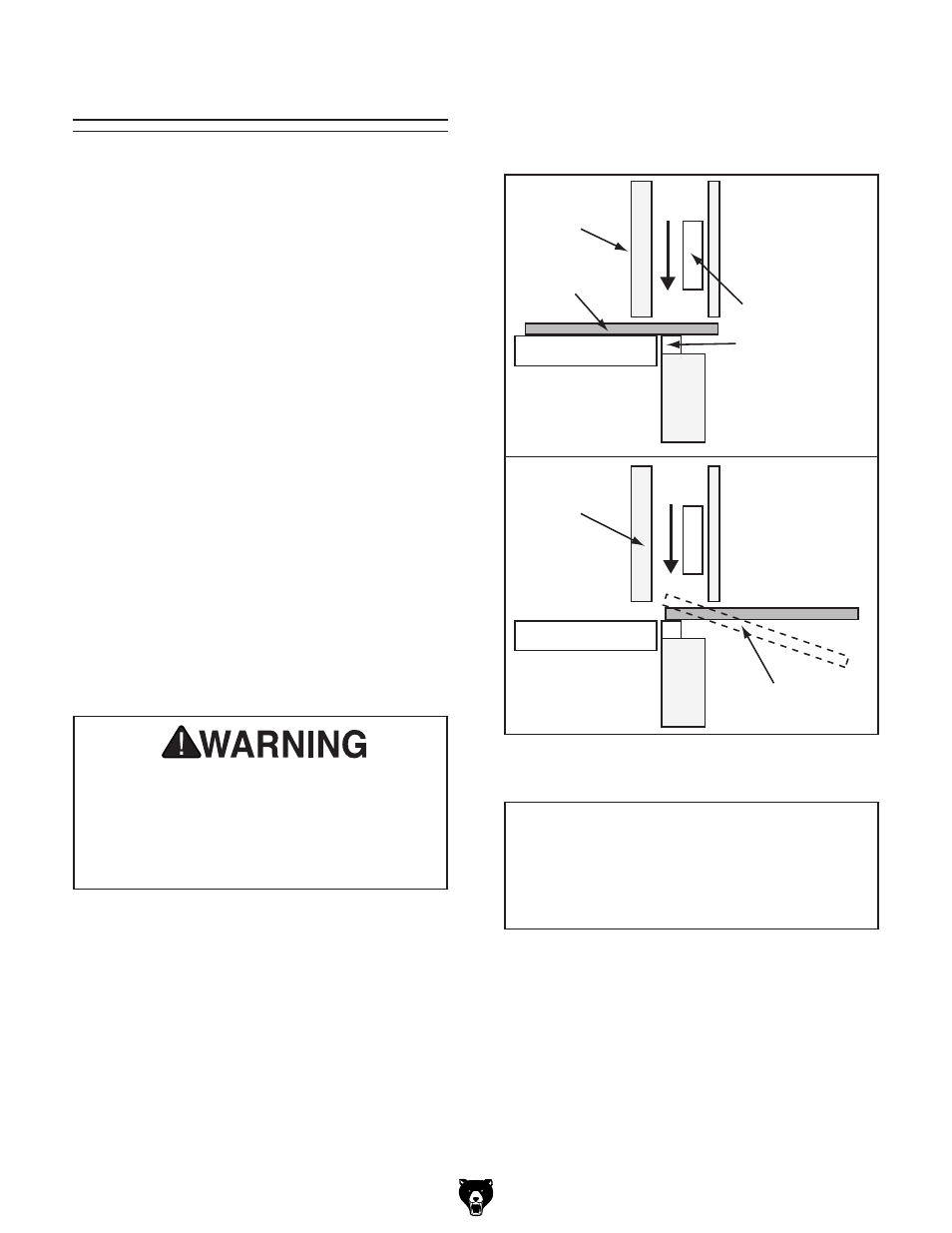

The workpiece MUST extend through the hold-

down and through the dies, as shown in

Figure 31,

to avoid sudden unexpected upward movement of

the workpiece during the cutting operation.

�����

���������

�������

����������

���������

�������

���������

��������

�����

���������

���������

���

�������

Figure 31. Flat stock shearing workpiece

position.