Beam alignment, Notice – Grizzly 50/65 Ton Ironworker G0646 User Manual

Page 44

-42-

G0646/G0647 50/65 Ton Ironworker

6. Reach through the opening in the top of the

reservoir left by the access plate and remove

the outlet filter from the reservoir.

7. Thoroughly clean the filler cap, both filters,

and the inside of the reservoir with solvent or

mineral spirits. Make sure to wipe and dry all

fluid residue from the parts, inside the reser-

voir, and the surrounding area.

Beam Alignment

As the beam slides back and forth between the

front and rear panels, four bronze pressure pads

keep the beam and the attached tooling prop-

erly aligned for safe and smooth operation. These

pressure pads wear under normal conditions and

require adjustment.

The tooling randomly being in and out of align-

ment is a strong indicator that the beam may need

alignment.

Tools Needed

Qty

Hex Wrench 8mm .............................................. 1

Hex Wrench 12mm ............................................ 1

Adjustable Wrench ............................................ 1

To align the beam:

1. DISCONNECT MACHINE FROM POWER!

2. Remove the shearing hold-down, shearing

support frame, and shearing table from the

machine.

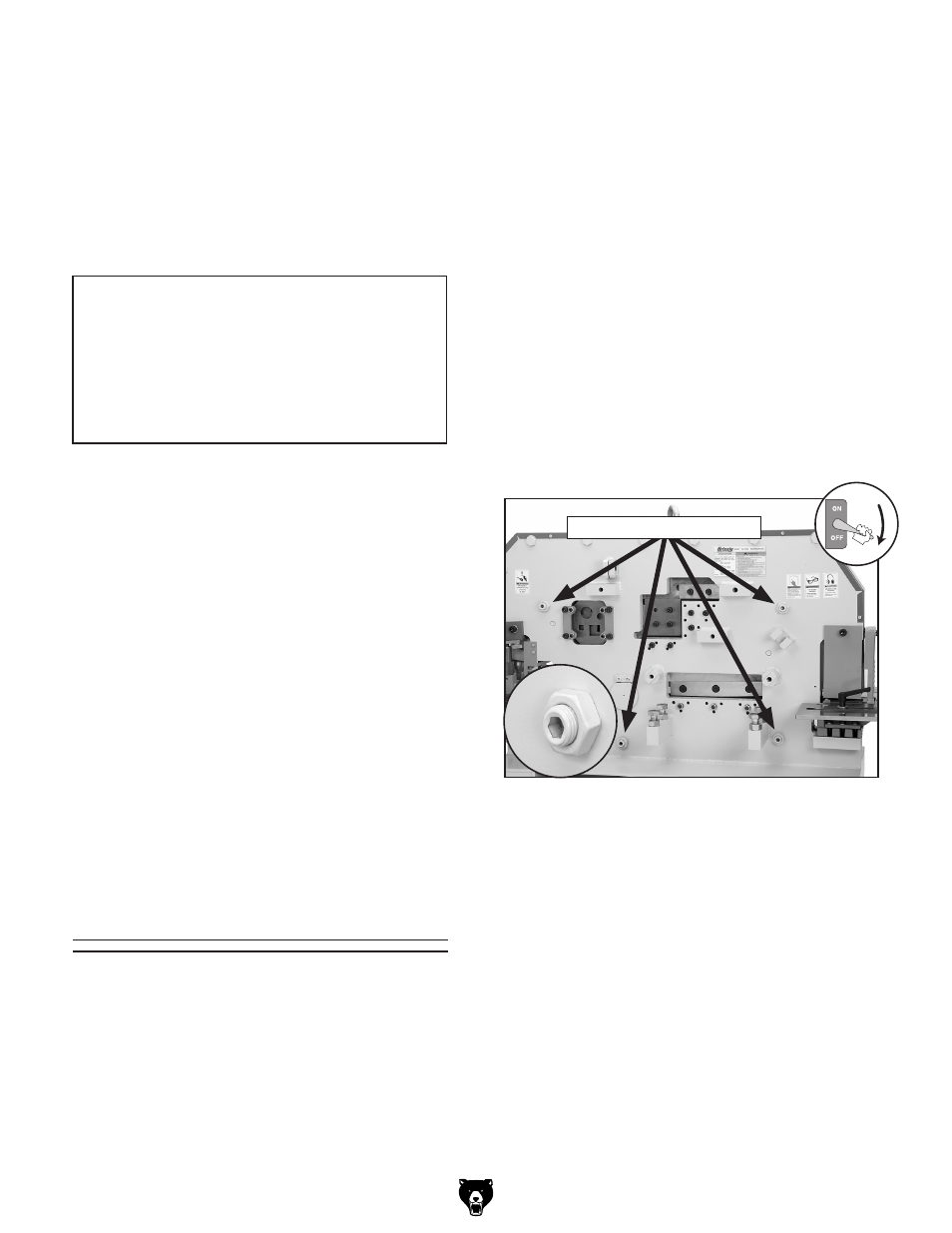

3. Identify the four beam adjustment lock nuts

and set screws on the front of the machine,

as shown in

Figure 58.

Figure 58. Beam adjustment lock nuts and set

screws.

Lock Nuts & Set Screws

4. Back off the lock nut, then loosen the set

screw (see the inset of

Figure 58).

5. With very light pressure, re-tighten the set

screw until you feel a slight drag.

6. While holding the set screw in place, re-

tighten the lock nut.

7. Repeat Steps 5–6 for the rest of the beam

adjustment lock nuts and set screws.

8. Re-install the shearing table, shearing sup-

port frame, and shearing hold-down.

beam alignment

NOTICE

If fluid contamination is severe or there has

been a component failure, have a qualified

hydraulic technician thoroughly flush the

system. Failure to follow this instruction

could lead to premature wear of the hydrau-

lic system and will void the warranty.

8. When all parts are clean and dry, re-assem-

ble them and fill the reservoir with one of the

recommended hydraulic fluids from

Figure

54 or an equivalent.

9. With the front and rear access panels removed

from the machine, re-connect the machine to

power and turn it

ON.

10. Carefully check all hoses and connections

for leaks, then stand clear of the machine

and move the beam back and forth to verify

proper operation of the hydraulic system.

Note: Use a clean piece of cardboard to

check for leaks—NOT your hands.

11. Turn the machine OFF, then re-install the

front and rear access panels.