2 start up & calibration – Pulsafeeder Digital Glycol Feeder DGF2 User Manual

Page 29

24

If a relay is in the FORCED OFF mode and power is lost, the relay will still be in the

FORCED OFF state when the unit is powered up again.

3.2

Start Up & Calibration

This section defines the procedure for starting your Digital Glycol Feeder for the first time.

1. Make all plumbing and electrical connections.

2. Fill the tank with glycol to a level adequate to turn off the low level alarm.

The pump is locked out in the automatic mode when the low level alarm is ON.

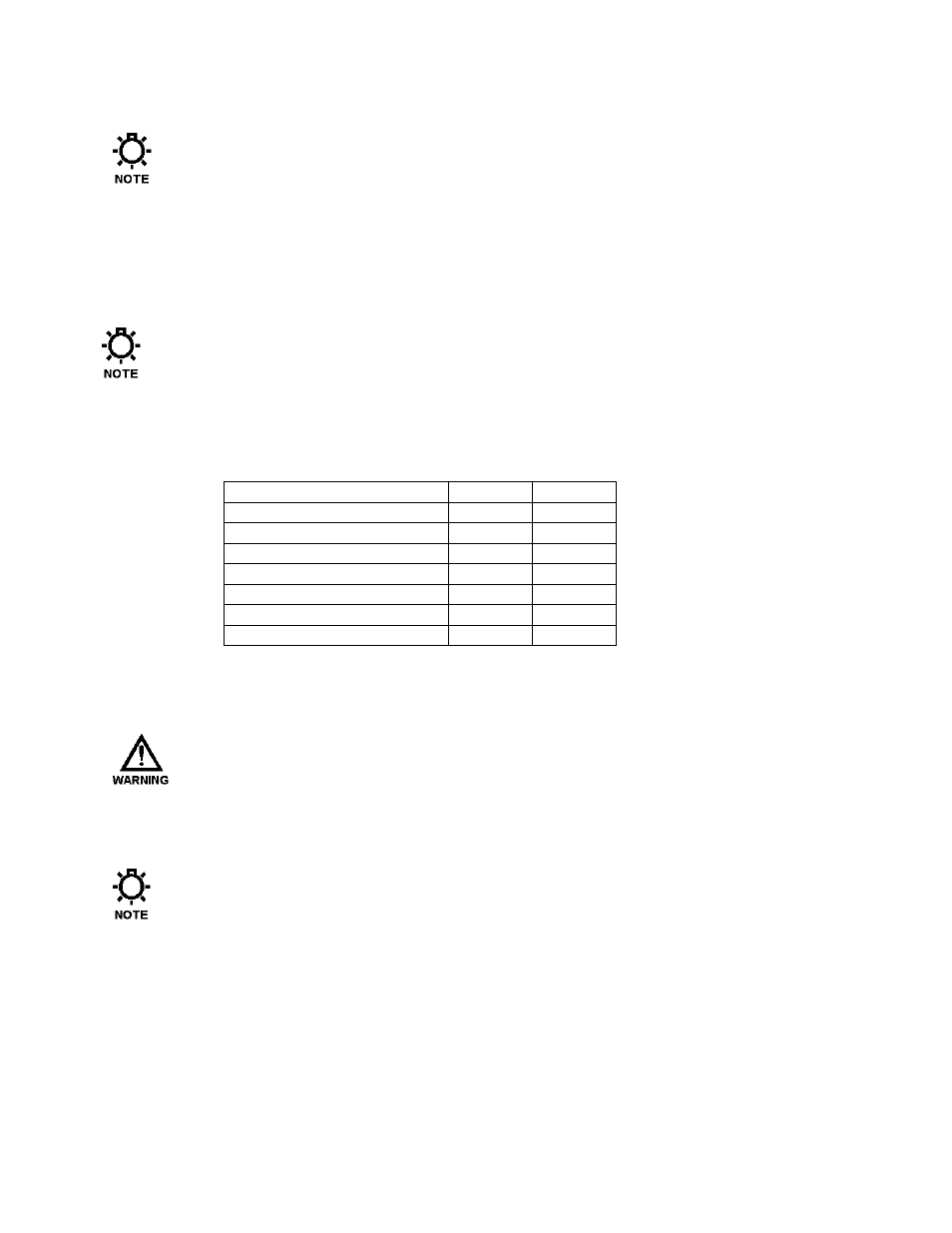

a) Filling the tank

Determine a percent by mixing water proportionally to a glycol solution.

Glycol

H

2

O

20% Glycol

Solution

2”

8”

30% Glycol

Solution

3”

7”

40% Glycol

Solution

4”

6”

50% Glycol

Solution

5”

5”

60% Glycol

Solution

6”

4”

70% Glycol

Solution

7”

3”

80% Glycol

Solution

8”

2”

3. Check for leaks.

4. Plug in the control box.

T

HE

PRESSURE

RELIEF

VALVE IS FACTORY SET AT

50

PSI

.

DO

NOT

OPERATE THE

D

IGITAL

G

LYCOL

F

EEDER ABOVE

100

PSI

.

I

F YOUR APPLICATION REQUIRES A HIGHER

OPERATING PRESSURE

,

CONSULT THE FACTORY

.

5. Force the pump(s) off by pressing the [PUMP] key once. (LED will be RED.)

6. Remove the Pressure Switch cap (refer to Figure 21) to make pressure switch adjustments.

The initial setting of the pressure switch is critical to the proper operation of the Digital

Glycol Feeder. The pressure gauge on the manifold system allows you to see the operating

pressure.

7. Pressurize the Glycol Feeder system by opening the Main Shutoff valve.