Installation and operations manual, Refrigerant line insulation, Refrigerant line support – Heatcraft Refrigeration Products PARALLEL COMPRESSOR SYSTEMS 25000102 User Manual

Page 8

8

Part # 25000102

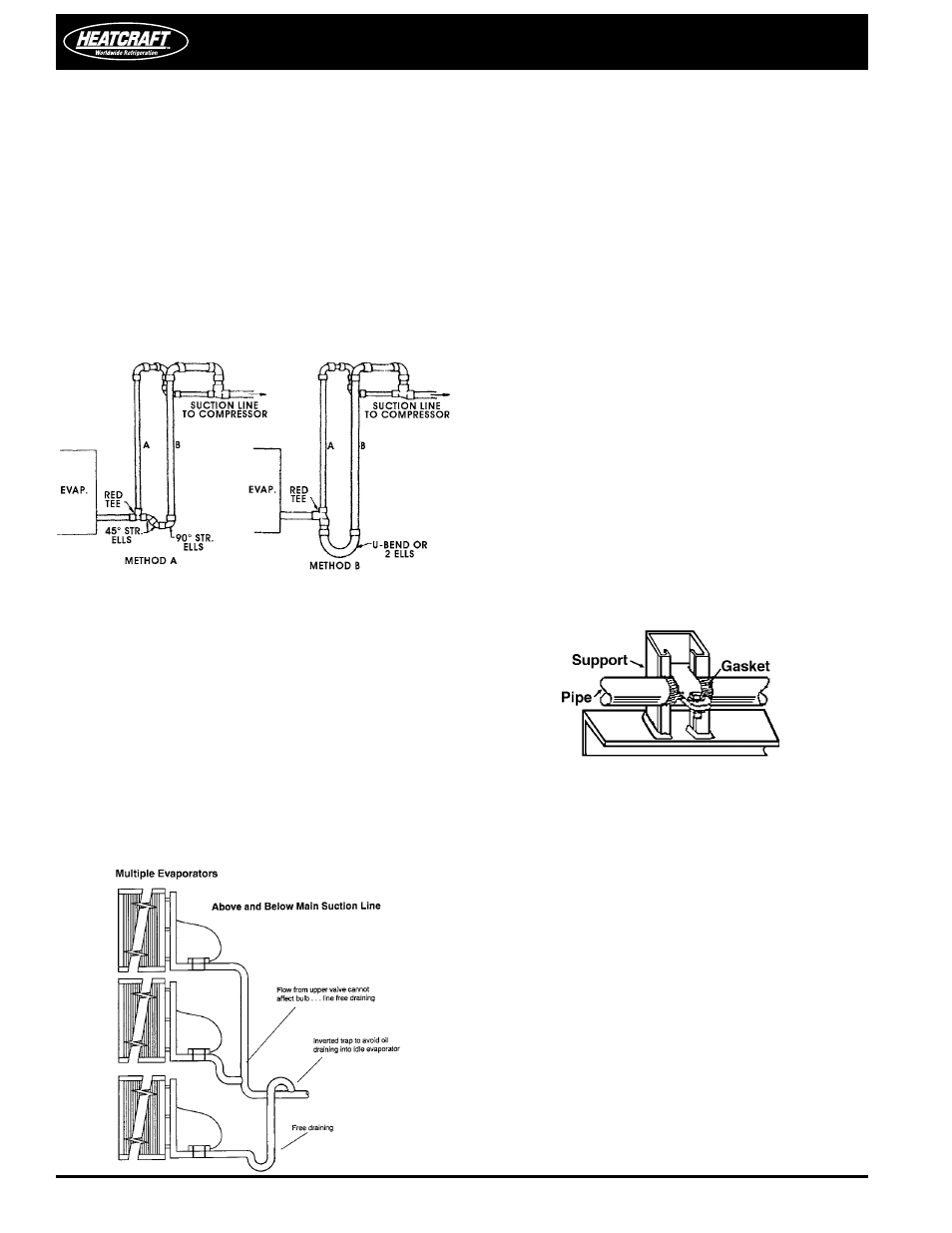

In systems equipped with capacity control compressors,

or where multiple compressors are used with one or more

compressors cycled off for capacity control, double suction

risers should be installed. See Figure 6 below. The two

lines should be sized so that the total cross-section area

is equivalent to the cross section area of a single riser that

would have both satisfactory gas velocity and acceptable

pressure drop at maximum load conditions. The two lines

normally are different in size, with the larger line trapped as

shown. The smaller line must be sized to provide adequate

velocities and acceptable pressure drop when the entire

minimum load is carried in the smaller riser.

•

In operation, at maximum load conditions gas and

entrained oil will be flowing through both risers. At

minimum load conditions, the gas velocity will not be

high enough to carry oil up both risers. The entrained oil

will drop out of the refrigerant gas flow and accumulate

in the “P” trap forming a liquid seal. This will force all of the

flow up the smaller riser, there by raising the velocity and

assuring oil circulation through the system.

When connecting more than one suction line to a main

trunk line, connect each branch line with an inverted trap.

See Figure 7 below:

•

•

Straight runs should be supported near each end.

Long runs require additional supports.

A general guide is:

3/8” to 7/8” every 5 feet

1-1/8” to 1-3/8” every 7 feet

1-5/8” to 2-1/8” every 10 feet

When changing directions, supports should be placed a

maximum of 2 feet in each direction.

Piping attached to a vibrating object (such as a compressor

or compressor base) must be supported in such a manner

that will not restrict the movement of the vibrating object.

Rigid mounting will fatigue the copper tubing.

Use only a suitable silver solder alloy on suction and liquid

lines.

Limit the soldering paste or flux to the minimum required

to prevent contamination of the solder joint internally. Flux

only the male portion of the connection, never the female.

After brazing, remove excess flux.

•

•

•

•

•

•

•

•

•

•

Installation and Operations Manual

When brazing refrigerant lines, an inert gas should

be passed through the line at low pressure to prevent

scaling and oxidation inside the tubing. Dry nitrogen is

preferred.

Use long radius ell’s for lower pressure drop.

Provide expansion loops in long straight refrigerant

lines that are subject to expansion and contraction. See

Expansion Loops in this manual for more information.

Refrigerant Line Insulation

Insulate suction lines from the evaporators to the parallel

unit with minimum 3/4” thickness closed-cell type

insulation on low temperature circuits. Insulate suction

lines on medium temperature circuits with minimum 1/2”

thick insulation to prevent condensation.

Long liquid lines run in areas exposed to high temperatures

should be fully insulated with minimum 1/2” insulation.

Suction and liquid lines should never be taped or

soldered together.

Refrigerant Line Support

Strap and support tubing to prevent excessive line

vibration and noise. All tubing clamps should have an

insulating material (i.e. Hydra Sorb bushing) to prevent

metal to metal contact.

•

•

•

•

•

•

•

Figure 6. Double Suction Risers

Figure 7. Inverted Trap

Figure 8. Pipe Support