Parallel compressor systems, Temprite models, Oil level regulators – Heatcraft Refrigeration Products PARALLEL COMPRESSOR SYSTEMS 25000102 User Manual

Page 27: Temprite valve adjustment

Parallel Compressor Systems Installation & Operations Manual, October 2004

27

Parallel Compressor Systems

to the compressor.

Before the oil separator is installed, an initial charge of oil must

be added to it. This initial charge of oil is the amount that is

needed to just float the needle valve float. This amount of oil

will stay in the oil separator when in operation and will seal

the needle and prevent damage to the float mechanism. Oil

Precharge is very important. Failure to Precharge the separator

sump may result in damage to the oil return float mechanism

by the turbulent hot gas bouncing the float and causing the

needle valve to leak.

New systems from the factory have been Precharged. Use

the same type of oil that is in the compressor crankcase.

See the table below for the proper amount of oil to be

Precharged.

Temprite Models

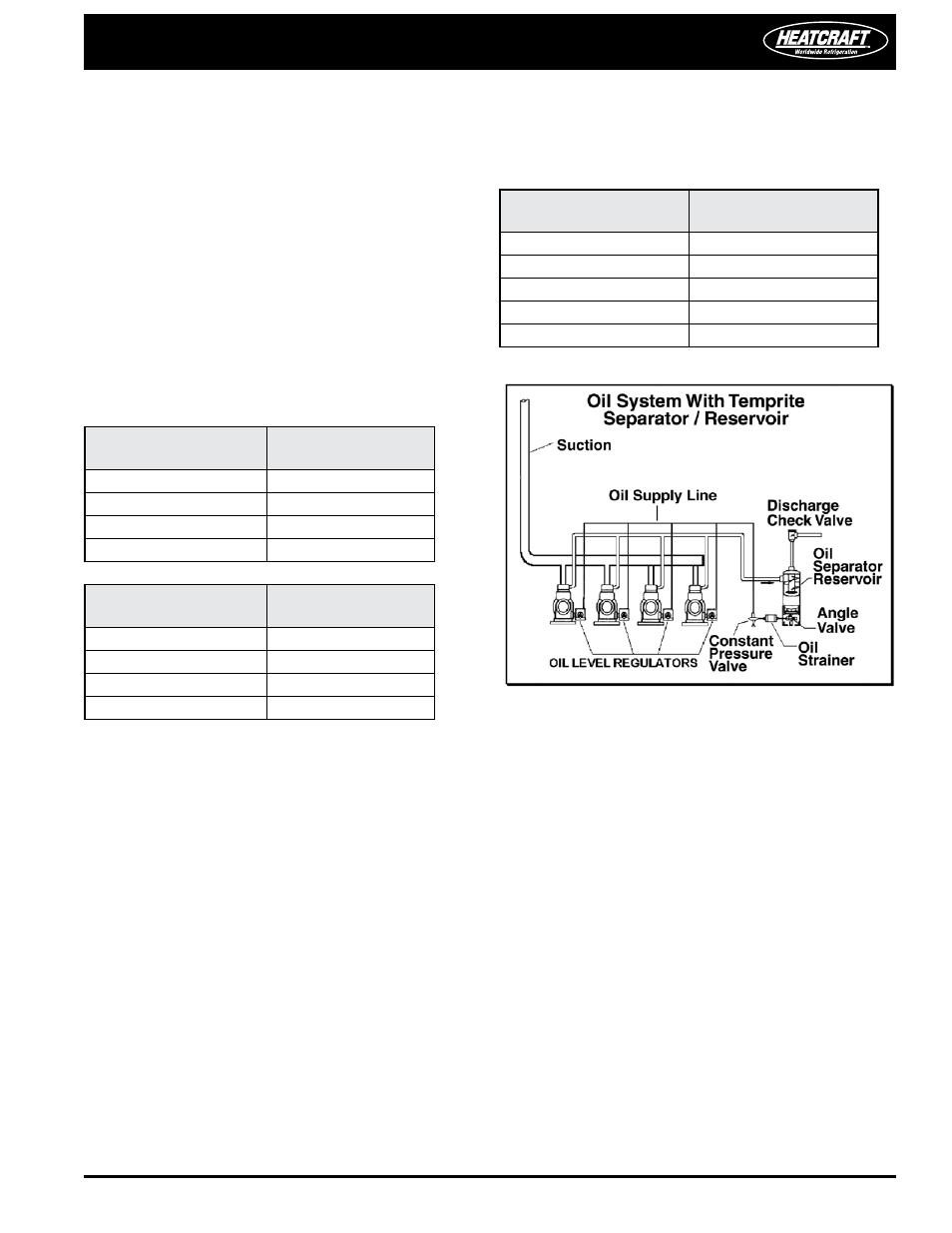

The Temprite brand used is the coalescent filter type separator.

Because this filter is finer than a filter/drier, it will pick up any

and all effluent and dirt circulating in the system down to 0.3

microns. These filters should be changed after 24 to 48 hours

of initial run time. A second filter is supplied with the system

for this purpose. If the filter becomes dirty, it will not function

at its optimum performance level. In the event of a compressor

burnout, all the effluent will be contained in the oil separator.

When the Temprite coalescent separator is used, the separate oil

reservoir is not required. The oil separator serves the additional

function as the reservoir. There is a constant pressure valve

used between the oil return outlet and the oil level regulators

to maintain a low pressure oil flow to the regulators. This

valve should be adjusted to maintain oil pressure to the level

regulators at 20 psig higher than the highest suction pressure

group. This valve can be adjusted by removing the external cap

and rotating the adjusting spring in or out as required.

The valve currently used is manufactured by Parker and is a

model A7 constant pressure expansion valve with a range of 0

to 90 psig. Temprite Part No. is 67070000. An alternative valve

manufactured by Sporlan is Model ADRI - 1

1

/

4

- 0/90.

Oil Level Regulators

The AC&R adjustable oil regulators are designed to feed oil

between 1/4 and 5/8 sight glass levels. The regulator may adjust

beyond this range due to the actual oil pressure. Adjustable

regulators include an adjustment mechanism to raise or lower

the oil set point. The AC&R design eliminates the need to shut

the system down in order to adjust the oil level. The oil level may

be adjusted while the system is under pressure and running.

Adjust the oil level by removing the seal cap, the locking disk

(S-9130 & S-9190 series only), and rotating the adjustment

clockwise to lower, counter clockwise to raise the oil level.

Replace the cap and locking disk when done. Each full turn of

the adjustment mechanism moves the oil level approximately

1/16”. Oil levels on these regulators are typically factory set just

below 1/2 sight glass.

All level regulators have a operating pressure differential range

that should not be confused with its working pressure. The

operating differential is the difference of pressure between

the oil feeding into the regulator and the component where

the regulator is controlling oil level. Specifically, the reservoir

pressure minus the crankcase pressure. If the differential

pressure is too low for that regulator, insufficient oil flow to the

compressor may result. If the differential pressure is too high,

the regulator will overfill.

Helical

Model No.

Oil

Precharge

S-5180, S-5181

4 oz. / 11 cl

S-5182, 85, 87, 88

14 oz. / 40 cl

S-5190, 92, 94

40 oz. / 114 cl

S-5200 / S-5410 series

25 oz. / 71 cl

Conventional

Model No.

Oil

Precharge

S-5500 series

12 oz. / 34 cl

S-5600 series

30 oz. / 86 cl

S-1900, S-5700 series

25 oz. / 71 cl

S-5800 series

12 oz. / 34 cl

Temprite Model

No.

Oil Precharge

922R, 923R

77 oz. / 2.2 L

924R , 925R

109 oz. / 3.22 L

926R, 927R

1.8 gal./ 6.7 L

928R

3.5 gal. / 13.25 L

930R

5.7 gal . / 21.25 L

Temprite Valve Adjustment

Turn in (clockwise) to increase pressure. Turn out

(counterclockwise) to decrease pressure. Approximately 7 psi

per turn. Factory set at 40 psi ±2.

Figure 17. Temprite Oil System

Table 20. AC&R Models

Table 21. Temprite Models