Recommended valve settings, Field adjustment, Hot gas bypass regulator adjustment – Heatcraft Refrigeration Products PARALLEL COMPRESSOR SYSTEMS 25000102 User Manual

Page 31: Sporlan valve company

Parallel Compressor Systems Installation & Operations Manual, October 2004

31

Parallel Compressor Systems

Liquid Drain Control Method

This method is ideal for large capacity systems since a smaller

regulator is required for liquid line than for discharge line.

During warm ambient temperature conditions valves A and

C will be open and Valve B will be closed. When the ambient

temperature at the condenser drops, the condenser pressure

will tend to become lower. As this pressure is reduced, when

the pressure becomes as low as its setting, Valve A will begin

to close, thus causing the refrigerant to back up inside the

condenser tubes, reducing the condensing surface and allowing

the pressure to be maintained. As Valve A closes, the receiver

pressure may be reduced by the cold entering liquid to a level

below the setting of Valve B, which will begin to open to bypass

sufficient gas to maintain the receiver pressure at the set point

of Valve B. Check valve C will prevent the high pressure from

backing up to the condenser when the receiver pressure is

higher than the condenser pressure, as would be the case

during shutdown in a system with a warm receiver.

When the condenser pressure builds up to the setting of Valve

A, it will open allowing liquid to flow to the receiver.

To describe it again, during cold ambient temperature

conditions this liquid will be considerably subcooled and will

tend to lower the receiver pressure. Valve B will sense the drop

in pressure and open to admit hot gas into the drain line, thus

pressurizing and warming the liquid and maintaining the

receiver pressure.

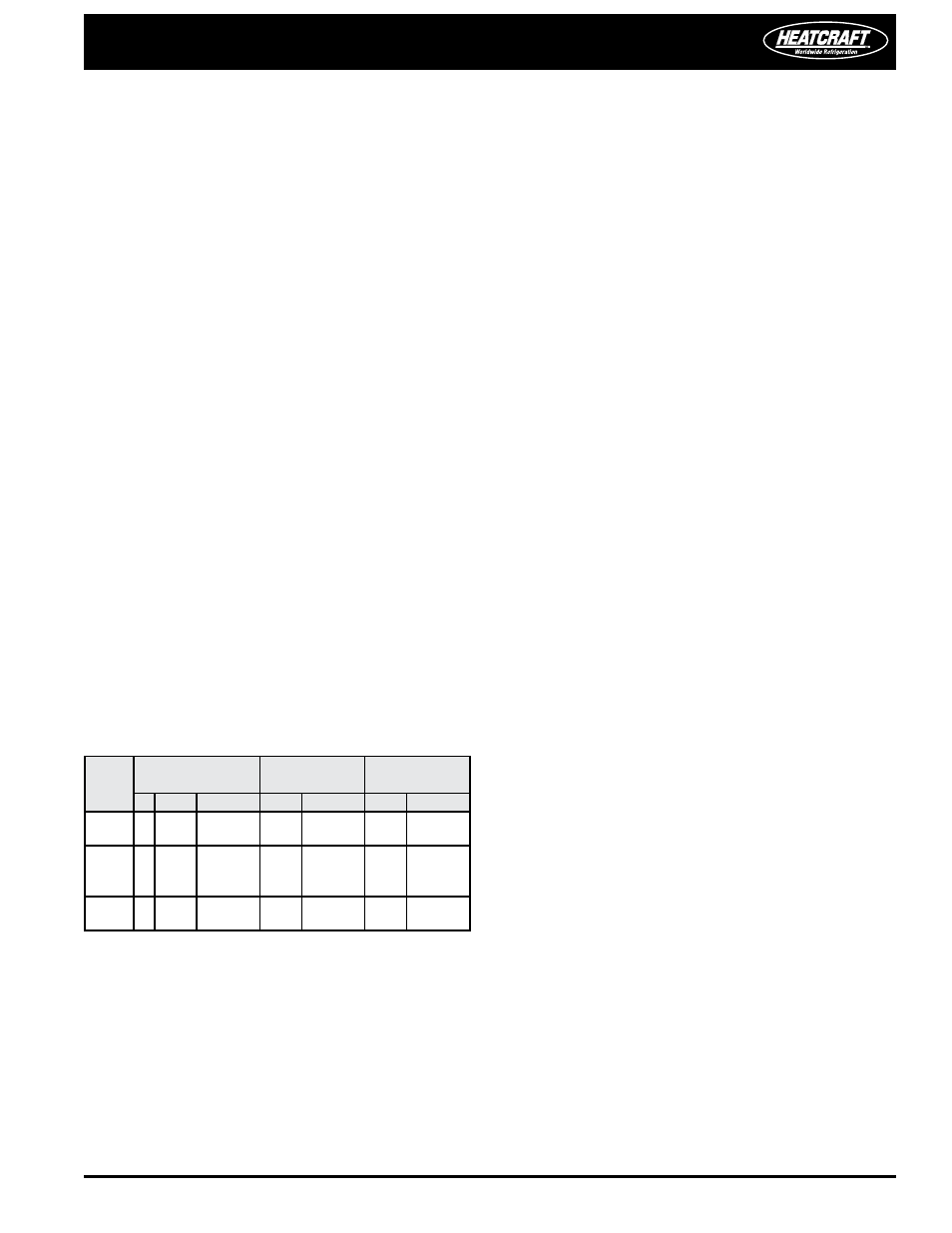

Recommended Valve Settings

Regulators ordered for a Condenser Pressure Control system for

use with common refrigerants will be furnished with the ranges

and factory settings shown in Table 29. Turning the adjusting

stem in (clockwise) will raise the set point; turning the stem

out (counterclockwise) will lower the set point. See Table 29 for

ranges and amount of pressure change per turn.

Valve

Type

Range

Factory

Set Point

Change Per

Turn

psig kg/cm

2

psig kg/cm

2

psig kg/cm

2

A4A

ARA0 D

75 to

280

5.2 to

19.7

140

9.8

53

3.7

A7A

A7A1

A72

D 75 to

280

5.3 to

19.7

120

8.4

75

5.3

A9

B 80 to

220

5.6 to

15.5

120

8.4

25

1.8

Field Adjustment

Before final field adjustment of regulators for Condenser

Pressure Control, the following should be done:

1. Install gauges to read compressor discharge, condenser and

receiver pressures.

2. Fully charge the system.

3. Have other controls and components functioning

properly.

4. Have the system as fully loaded as possible.

5. Final adjustments should be made when the outdoor

ambient is below 65°F. Ideally the ambient should be near

minimum system outdoor temperature to allow the system

pressures to drop below the regulator pressure settings.

Before adjusting make sure that all manual opening stems

on the regulators are set for automatic operation. It may

be necessary to temporarily deactivate the low pressure

cut out controls to keep the compressors running during

adjustment.

6. The regulators should be preset using information in Table

29.

7. When the valves are adjusted with the system operating,

enough time must be allowed for the system to stabilize.

Check the sight glass to make sure sufficient liquid is

supplied to the evaporators.

8. Turn the condenser fans off to allow the discharge pressure

to build up. The regulator A should be adjusted to open

when the pressure reaches the desired control point. Listen

for flow through regulator A while watching the pressure

gauge.

To determine the final setting of regulator B, allow the condenser

fans to run long enough to subcool the liquid supplied to the

receiver. Adjust the regulator until the desired receiver pressure

is obtained. Flow through the valve can be determined by

listening at the valve for gas flow or by feeling the outlet for

change in temperature. The setting of regulator B should be at

least 10 psi lower than the setting of regulator A.

Hot Gas Bypass Regulator Adjustment

Discharge Bypass Valves (DVB) respond to changes in

downstream or suction pressure. When the evaporating

pressure is above the valve setting, the valve remains closed.

As the suction pressure drops below the valve setting, the valve

responds and begins to open. As with all modulating type

valves, the amount of opening is proportional to the change in

the variable being controlled - in this case the suction pressure.

As the suction pressure continues to drop, the valve continues

to open farther until the limit of the valve stoke is reached.

On refrigeration systems discharge bypass valves are used to

prevent the suction pressure from going below the minimum

value determined by the job requirements.

Sporlan Valve Company

Valve Setting and Adjustment

A complete discussion on valve settings is given in Sporlan

Application Bulletin 90-40. The fully adjustable models ADRS(E)-

2, ADRP(E)-3, and ADRH(E)-6 are available with two adjustment

ranges - 0/30 and 0/80 psig. The standard factory settings

for these are 20 and 60 psig, respectively. The ADRI(E)-1-1/4

is available with a 0/55 psig range and the standard factory

setting is 28 psig.

To adjust these valves, remove the cap an turn the adjustment

nut with a 5/16” hex wrench for fully adjustable models

ADRS(E)-2, ADRP(E)-3, and ADRH(E)-6. The ADRI(E)-1-

1/4 model has a 3/8” adjustment screw on top of the

adjustment housing. A clockwise rotation increases the

setting and a counterclockwise rotation decreases the setting.

Adjusting these valves can be complicated because the load

Table 29. Pressure Range, Set Point &

Charge Per Turn