Oil control, Low pressure oil system, Oil separators – Heatcraft Refrigeration Products PARALLEL COMPRESSOR SYSTEMS 25000102 User Manual

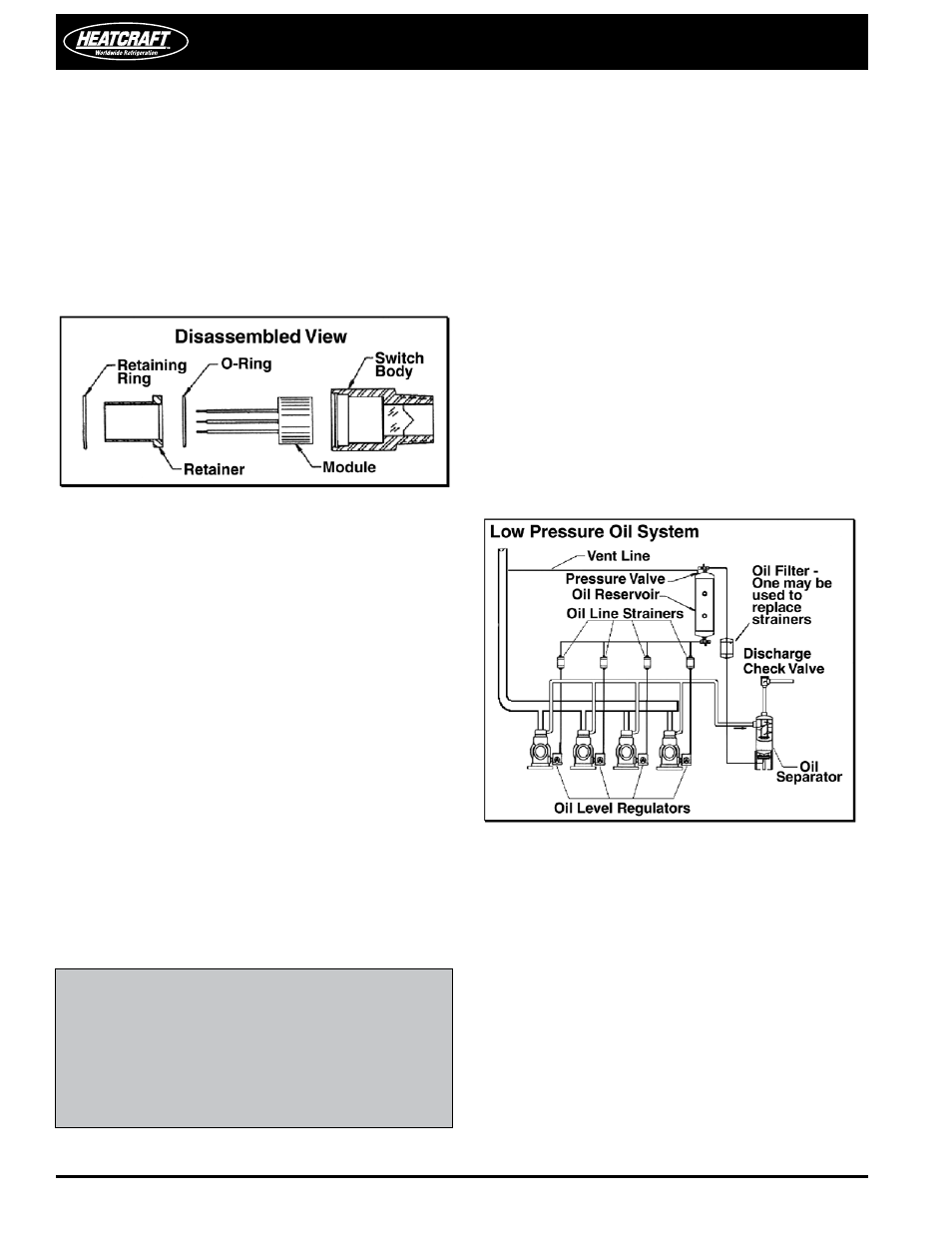

Page 26: Figure 15. figure 16. low pressure oil system

26

Part # 25000102

Installation and Operations Manual

Module Replacement

1. Disconnect power at the fuse box

2. Remove wiring box from the retainer

3. Remove the IRR 4000-93 Ring with an IRR P-101 or equivalent

retaining ring pliers

4. Remove the Retainer

5. Pull out the module by the leads

6. Install new Module

7. Verify the voltage rating

8. Reassemble the Retainer, Ring, and wiring

Oil Control

A proper oil control system is essential to insure compressor

lubrication. An oil control system can be very cost effective

alternative to replacing expensive compressors due to loss of

oil. Oil traveling through the system tends to build up in the

evaporator, condenser, and vessels of a refrigeration system.

This causes a lack of oil return to the compressor until finally, a

large amount returns as a “slug” of oil.

A slug of oil down the suction line can be just as damaging to

the compressor as a slug of liquid refrigerant. This delay in oil

return requires an additional amount of oil to be added to the

system, depending on the size of the system, the piping, the

temperatures, the miscibility of the refrigerant/oil mix, and the

refrigerant velocity.

By removing oil from the discharge gas of compressors, not

only is the oil level for each compressor more accurately

controlled, the efficiency of the system is increased. Oil does

not change phase from liquid to gas in a refrigeration system

and therefore makes a very poor refrigerant. Oil also takes up

volume through the system that otherwise could be filled with

refrigerant. Additionally, oil tends to film the condenser tubing

wall lowering heat transfer and as oil and refrigerant exits the

expansion valve, the oil will foam insulating the evaporator

walls and again lowering heat transfer.

IMPORTANT: An oil control system does not replace

the need for proper system design. An

oil control system will drastically reduce

the amount of oil going through the

system. Correct piping, suction traps,

and proper sizing of valves, controls, and

components must still be implemented

to insure the system will work properly.

Low Pressure Oil System

This type system is normally used for parallel compressors and

uses three basic components: Oil Separator, Oil Reservoir, and

Oil Level Regulators. The common discharge is piped to the

inlet of the oil separator and the outlet of the oil separator is

piped to the condenser. An oil return line is brought from the

oil separator to the top valve of the oil reservoir. A vent line is

installed to the suction line with a pressure valve in line to lower

the pressure in the reservoir, making a low pressure oil system.

This valve will keep the reservoir pressure a set pressure above

suction depending on the value of the valve, either 5 or 20 psig

to the oil level regulator. Mechanical oil level regulators are

rated for pressures ranging from 5 to 90 psig differential. The

bottom valve of the oil reservoir is piped to oil level regulators

mounted on the compressor crankcases. These regulators open

to feed oil as the oil level drops and closes as the oil level raises

to the set level. In this manner, the oil level in the compressor

is kept at a constant level. Either one oil strainer per regulator

or one oil filter per separator must be used to remove debris

from the oil.

Oil Separators

There are two types of oil separator that may be used in

the Heatcraft parallel racks. One type utilizes the standard

impingement screen. This type separator works by having the

compressed mass flow enter into a large separator chamber

which lowers the velocity and then the atomized oil droplets

collect on the impingement screen surface. As the oil droplets

collect into larger particles they fall to the bottom of the

separator.

The second separator more commonly used is the coalescent

type. This type separator contains a matrix type borosilicate

coalescent filter to do the work impingement screens formerly

did. The exceptionally pure, extremely fine glass fibers matrices

excite the oil molecules to collide into one another thus

agglomerating them into bigger droplets until they are forced

to the outer drain layer of the filter. These droplets fall to the

bottom of the separator reservoir and the oil is then returned

Figure 15.

Figure 16. Low Pressure Oil System