Parallel compressor systems suction filter, Compressor motor burnout cleanup procedure, Sporlan valve company – Heatcraft Refrigeration Products PARALLEL COMPRESSOR SYSTEMS 25000102 User Manual

Page 29

Parallel Compressor Systems Installation & Operations Manual, October 2004

29

Parallel Compressor Systems

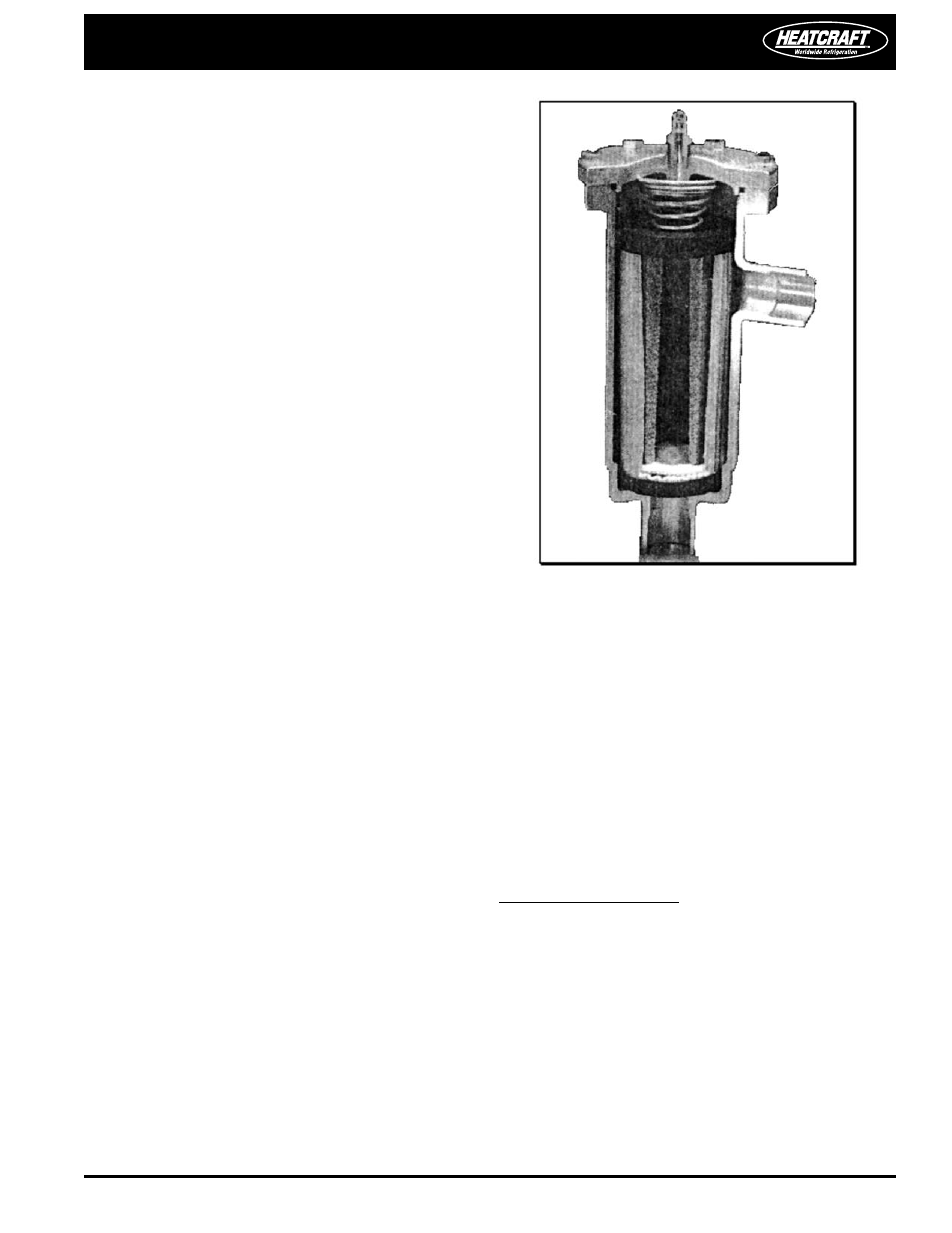

Suction Filter

Replaceable core suction filters are supplied as standard

on all units. The flanged shell holds replaceable pleated

filter elements suitable for installation in the suction line of

refrigeration systems. In this way any contaminants left in the

system at start-up can be removed before they circulate back

to the compressor. The suction filters are shipped loose for

field installation. (See No. 3 of Leak Checking, Evacuation, and

Start-up section in this manual).

Compressor Motor Burnout Cleanup Procedure

Another benefit of the suction filter is its use in cleanup of a

system after a burnout. Standard liquid cores can be installed in

the shell to aid in the cleanup of acids and other contaminants

from a motor burnout.

The following procedure can be used in case of a motor

burnout.

1. Determine the extent of the burnout. For mild burnout’s

where contamination has not spread through the system,

it may be economical to save the refrigerant. Normally

it is economical to save the refrigeration charge if the

system has service valves. A severe burnout exists if the oil

is discolored, an acid odor is present and contamination

products are found in the high and low side. With this

condition, extreme caution should be exercised to avoid

breathing the acid vapors and to prevent contaminated

liquid from making contact with the skin.

2. Thoroughly clean and replace all system controls, such

as expansion valves, solenoids, check valves, reversing

valves, oil separators, suction accumulators, etc. Remove

all strainers and filter-driers.

3. Install a replacement compressor and make a complete

electrical check.

4. Make sure the suction line adjacent to the compressor

is clean. Install a liquid line filter-drier or a replaceable

cartridge designed for “cleanup” into the suction line

shell.

5. Install a burnout core in the liquid line shell.

6. If the refrigerant is removed from the system, follow the

evacuation procedure found on page 17 of this manual.

7. Start the compressor and put the system in operation.

Record the pressure drop across the suction line filter and

keep for reference.

8. Replace the suction line filter-drier blocks if the pressure

drop becomes excessive.

9. Observe the system during the first 4 hours. Repeat step

8 as often as required, until no further change in pressure

drop is observed.

10. After the system has been in operation for 48 hours, check

the condition of the oil for Acids. If the oil test indicates an

acid condition, replace the liquid and suction line filter-

driers.

11. Check the system again after approximately 2 weeks of

operation. If the oil is still discolored, or checks acid, replace

the liquid and suction line filter-driers.

12. Cleanup is complete when the oil is clean, odor free, and is

determined to be acceptable by testing for acids or other

contaminants.

13. Replace the suction line filter-drier with suction line filters

cores to minimize suction line pressure drop and to provide

maximum compressor protection.

For more detailed information on burnout cleanup procedures

and recommendations, consult the RSES Service Manual,

section 91.

Sporlan Valve Company

Replaceable Suction Filter

The correct replacement suction filter element in Sporlan Valve

replaceable shells is Sporlan part number RFE-48-BD. However

any suitable filter that is sized to fit a 48 cu. inch vessel will

substitute.