Rigging, Location of equipment - indoor clearances, Floor & foundation requirements – Heatcraft Refrigeration Products PARALLEL COMPRESSOR SYSTEMS 25000102 User Manual

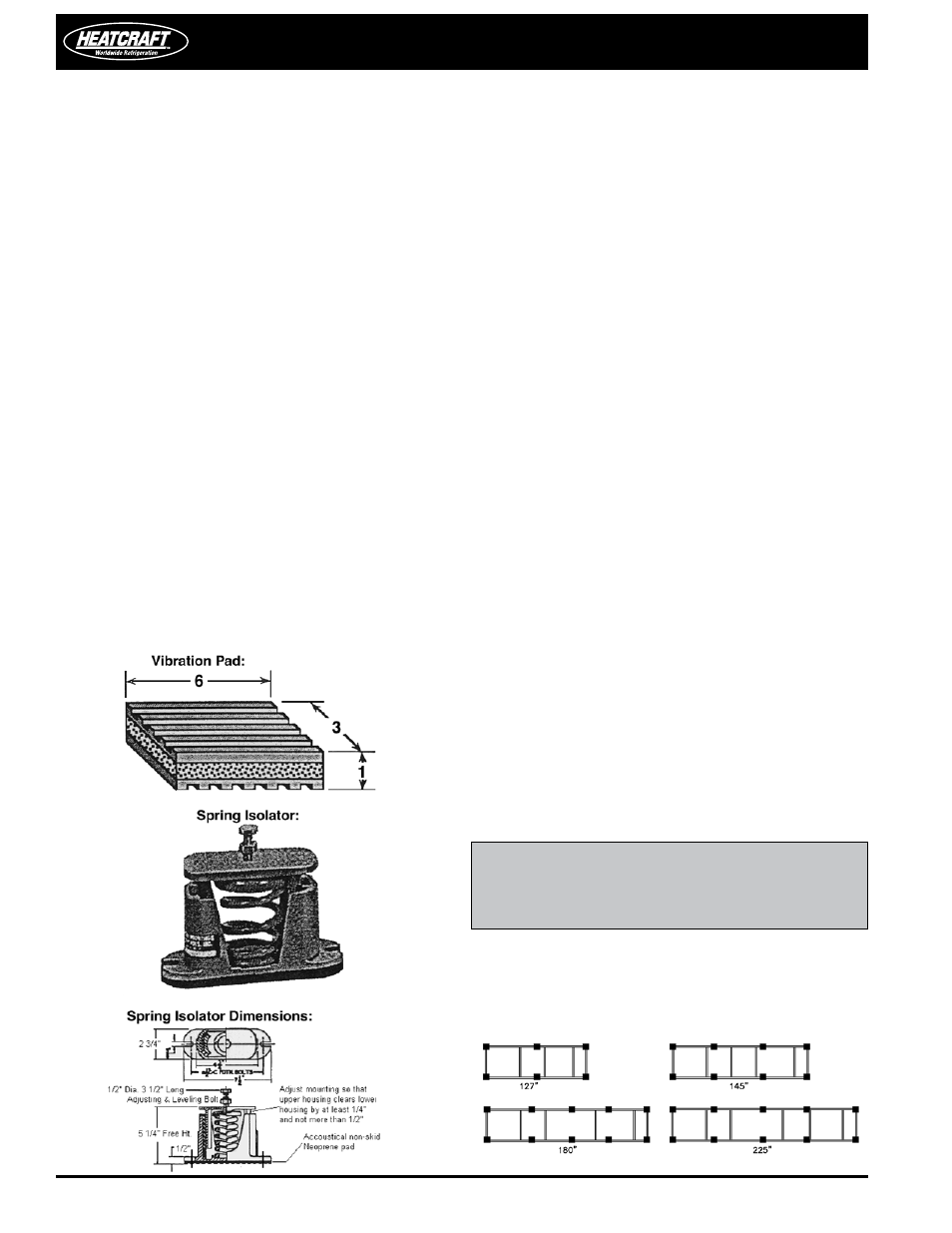

Page 4: Vibration mounts, Figure 1. vibration pad and spring isolator

4

Part # 25000102

Installation and Operations Manual

Figure 2. Vibration Pad Locations

System Warranty

This equipment is designed to operate properly and produce

the rated capacity when installed in accordance with good

refrigeration practice.

The following conditions should be adhered to when installing

this unit to maintain the manufacturers warranty:

(a) System piping must be in accordance with good

refrigeration practices

(b) Inert gas must be charged into the piping during

brazing

(c) The power supply to the unit must meet the following

conditions:

• All voltages must be +/- 10% of the n a m e p l a t e

ratings

• Phase (voltage) imbalance cannot exceed 2%

(d) All control and safety switch circuits must be properly

connected according to the wiring diagram

(e) The factory installed wiring must not be changed without

written factory approval

Rigging

Warning: Careful considerations for lifting should be made

before the unit is lifted by any means. The only part of the unit

designed to carry any of the lifting load is the welded channel

base. The unit may be lifted at the base with a forklift or by

means of cables at the four corners of the base. If cables are

used, the lifting cables should be prevented from contacting

any of the unit piping or electrical components.

Location Of Equipment - Indoor

Clearances

The parallel systems should be located so they are level and

easily serviced. The minimum suggested clearance around

the units should be 24 inches at the rear and 42 inches in the

front of panel (or as required by National or Local Codes). For

parallel system units placed end to end, 24 inches between

units is suggested.

Floor & Foundation Requirements

The total weight of a single unit will vary between 1200 pounds

and 10,000 pounds. Allowances must be made for the parallel

rack and all other equipment installed in the same area as the

parallel units. The location and installation of all equipment

should be in accordance with all local and national code

requirements.

While each unit is constructed with a welded steel base frame

adequately designed to withstand vibration, the natural

pulsating action of the interconnected motor-compressors

may cause considerable noise and vibration if the unit is not

mounted on a firm level surface and isolated from the structure

of the building.

Vibration Mounts

In ordinary ground level or basement installations, all that is

necessary to assure a vibration-free installation is to place the

unit on the concrete floor with the waffle-surfaced resilient pads

supplied. See Figure 2 for suggested pad locations. Mezzanine

and other installations require some special considerations.

The equivalent of 6 inch thick properly reinforced concrete

floor must be provided for mounting parallel units above

grade. It is recommended that the suggestions previously

given for rigid floor construction on above-grade installations

be closely adhered to. If this is not possible, special vibration

NOTE: Turn each leveling nut until the tip casting

rises 1/4” to 3/8” above the bottom

casting. MOUNT ADJUSTMENT SHOULD

NEVER EXCEED 3/4”.

Figure 1. Vibration Pad and Spring Isolator