Installation and operations manual, Alco controls, Control settings – Heatcraft Refrigeration Products PARALLEL COMPRESSOR SYSTEMS 25000102 User Manual

Page 32: Low pressure switch setting for rmcc, Table 31. control settings for r-22

32

Part # 25000102

Installation and Operations Manual

must be varied during the setting procedure and it is difficult

to determine exactly when the bypass valve opens unless a

pressure gauge can be located at the valve outlet.

Therefore, sufficient load must be available in some form to

raise the suction pressure above the desired valve setting. Once

this is accomplished, the load can be slowly decreased until the

DBV opens (a hissing sound and/or an accompanying pressure

rise at the outlet connection will indicate that the bypass valve

has opened).

Alco Controls

Valve Setting and Adjustment

CPHE and DGRE regulators are commonly used to prevent the

suction pressure from falling below a predetermined set point.

Complete information about these valves can be found in ALCO

CONTROLS Catalog 24-D.

The first step after installation is to determine the set point for

the minimum suction pressure allowable for the application.

The following procedure should be followed.

1. Start the system and determine if it is operating properly:

Install a gauge on the compressor suction line and measure

the suction pressure after the system has stabilized. To make

certain that hot gas is not being bypassed, listen to the main

regulator flow or feel the outlet piping. If the piping is warm,

this would indicate hot gas is flowing.

2. Stop the flow of hot gas by de-energizing the hot gas

solenoid valve or by turning the power assembly adjusting

stem full C

ounteRCloCkwise

.

3. Reduce the evaporator load until the suction pressure lowers

to the point at which bypass is desired.

4. If the hot gas solenoid was de-energized to stop hot gas

flow, make sure it is now energized.

5. Turn the power assembly adjusting stem in a C

loCkwise

direction until bypass occurs and suction pressure does

not fall below the predetermined set point. A C

loCkwise

turn

of the adjusting stem will increase the pressure setting; a

C

ounteRCloCkwise

turn will decrease it. Standard pressure pilot

is adjustable from 0 to 80 psig, with one complete turn equal

to approximately 4 psi change. Adjustments should be made

in small increments, allowing for the system to stabilize after

each turn.

6. Vary the evaporator load to test at various conditions that

the suction pressure does not fall below the predetermined

set point.

7. Replace the seal cap on the adjusting stem.

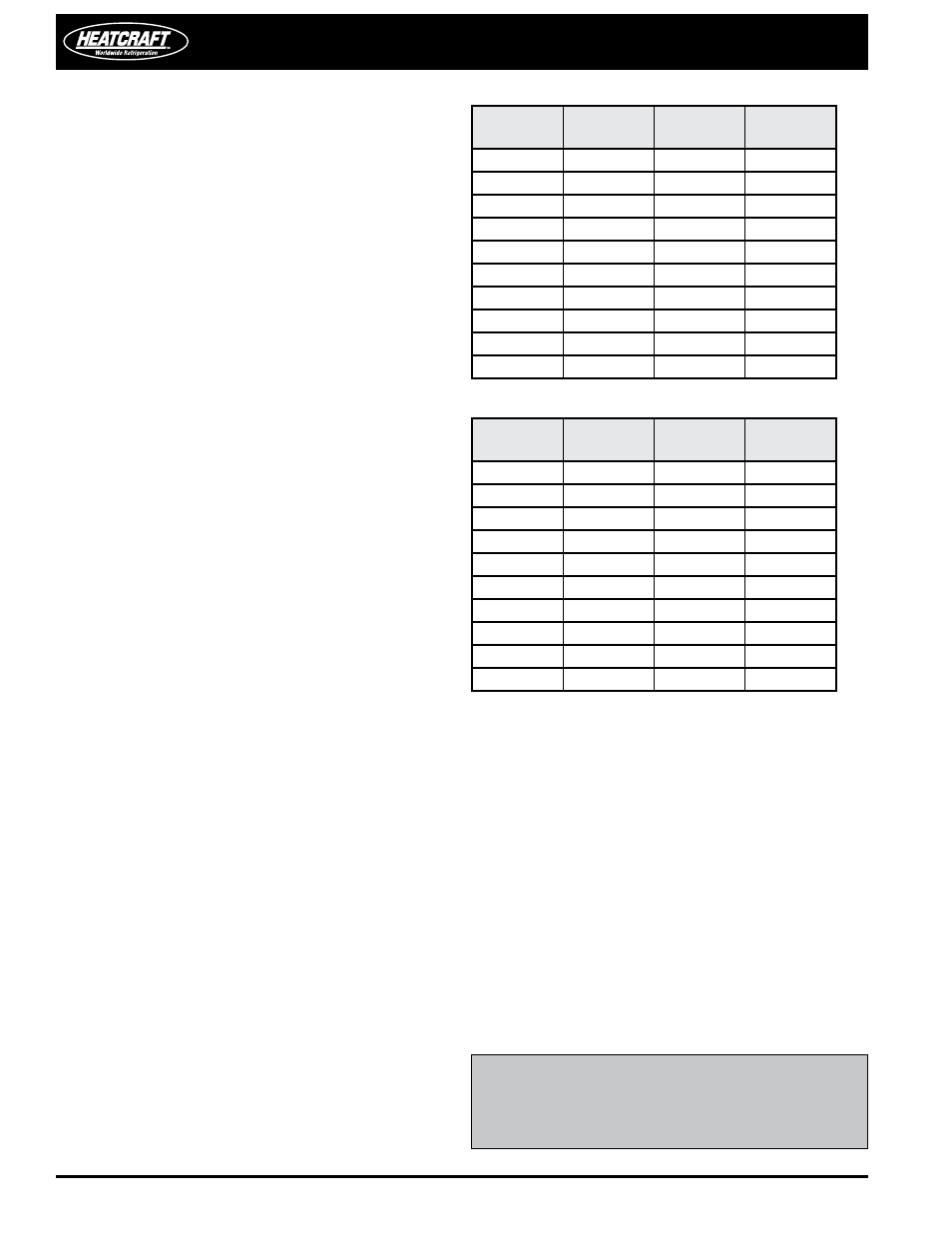

Control Settings

The following tables are for use when mechanical low pressure

switches are incorporated for rack pressure control. All control

settings are approximate and should be adjusted for actual

field conditions and equipment. All settings are based on 10°F

TD evaporator.

Low Pressure Switch Setting for RMCC

Some systems use a form of electronic control such as CPC’s

RMCC solid state controller for Rack operation. On these

systems, there is one mechanical low pressure control for each

suction group that may be on the rack. This control is for backup

emergency control in the event of a board or other electronic

component failure. This low pressure control must be set for the

minimum suction pressure that the rack would be expected to

operate at to keep from interfering with the RMCC control.

Example, for a low temperature suction group, this control

should be set for 0 - 2 psig cutout and approximately 10 psig

cutin. A medium temperature suction group can be set higher.

In the event that this control is needed to actually control the

compressors, set the cutin and cutout for the suction pressure

that you want the compressors to operate to maintain case or

box temperatures.

NOTE: This low pressure control will generally be

mounted on a compressor with the braided

stainless steel tubing connecting to the

appropriate suction group header.

Table 30. Control Settings for R-404A/R-507

Air Temp

°F

EPR

psig

LP C/I

psig

LP C/O

psig

38-42

69

72

64

34-38

64

66

57

34-36

60

62

55

33-35

59

61

53

28-32

55

58

50

24-28

48

50

35

-10-/0

21

24

15

-10-/-5

20

22

14

-15-/-10

15

17

14

-20-/-15

12

15

8

Table 31. Control Settings for R-22

Air Temp

°F

EPR

psig

LP C/I

psig

LP C/O

psig

38-42

54

57

50

34-38

50

48

43

34-36

47

50

41

33-35

45

47

40

28-32

43

45

38

24-28

36

38

25

-10-/0

13

17

8

-10-/-5

11

14

7

-15-/-10

8

10

5

-20-/-15

5

8

2