Ventilation requirements indoor units, Electrical, Refrigerant piping – Heatcraft Refrigeration Products PARALLEL COMPRESSOR SYSTEMS 25000102 User Manual

Page 7: Suction p-traps

Parallel Compressor Systems Installation & Operations Manual, October 2004

7

Ventilation Requirements

Indoor Units

If compressors or condensing units are located in a machine

room, adequate ventilation air must be provided to avoid

an excessive temperature rise in the room. To allow for peak

summer temperatures a 10°F temperature rise is recommended,

although a 15°F rise might be acceptable.

With compressors with remote condensers, approximately 10%

of the heat rejected is given off by the compressor casting and

the discharge tubing. The correct formula for calculating the

ventilation requirement of the Indoor Parallel unit is:

CFM = 10% of THR / hr

10° TD

The air intake should be positioned so that air passes over the

units. All State, Local, and National codes should be followed.

Electrical

To insure the proper operation of equipment and reduce the

possibility of interruption of refrigeration due to electrical

power failure, the following precautions must be observed:

• All electrical work must be done in accordance with the

National Electrical Code and existing local codes

• The power supply must be the same as specified on the unit

data plate

• An adequate power supply must be provided

• Voltage fluctuations in excess of 10 percent must

be corrected

• Overload relays (Carrier compressors only) are selected

in accordance with specified limits as determined by the

motor-compressor manufacturer. They must not be changed

in size or shorted-out

• Control panels must be provided with a single phase, 60

Hertz supply. See the unit wiring diagram for the voltage

requirement

• Before starting up a parallel unit, insure that all fuses and

motor-protective devices are in place and that all wiring is

secure. A complete wiring diagram for troubleshooting the

unit will be found inside the control panel cover

Refrigerant Piping

The system as supplied by Heatcraft, was thoroughly cleaned

and dehydrated at the factory. Foreign matter may enter the

system by way of the field piping required. Therefore, care must

be used during installation of the piping to prevent introduction

of foreign matter.

Install all refrigeration system components in accordance with

all applicable local and national codes and in conformance

with good practice required for the proper operation of the

system.

Proper size refrigeration lines are essential to good refrigeration

performance. Suction lines are more critical than liquid or

discharge lines. Oversized suction lines may prevent proper oil

return to the compressor. Undersized lines can rob refrigeration

capacity and increase operating cost. Consult the line sizing

charts in this manual for proper pipe sizes.

The following procedures should be followed:

1. Do not leave dehydrated compressors or filter-driers open

to the atmosphere

2. Use only refrigeration grade copper tubing, properly sealed

against contamination

3. Suction lines should slope 1/4” per 10 feet towards the

compressor

4. Discharge lines should slope 1/4” per 20 feet toward the

condenser

Suction P-Traps

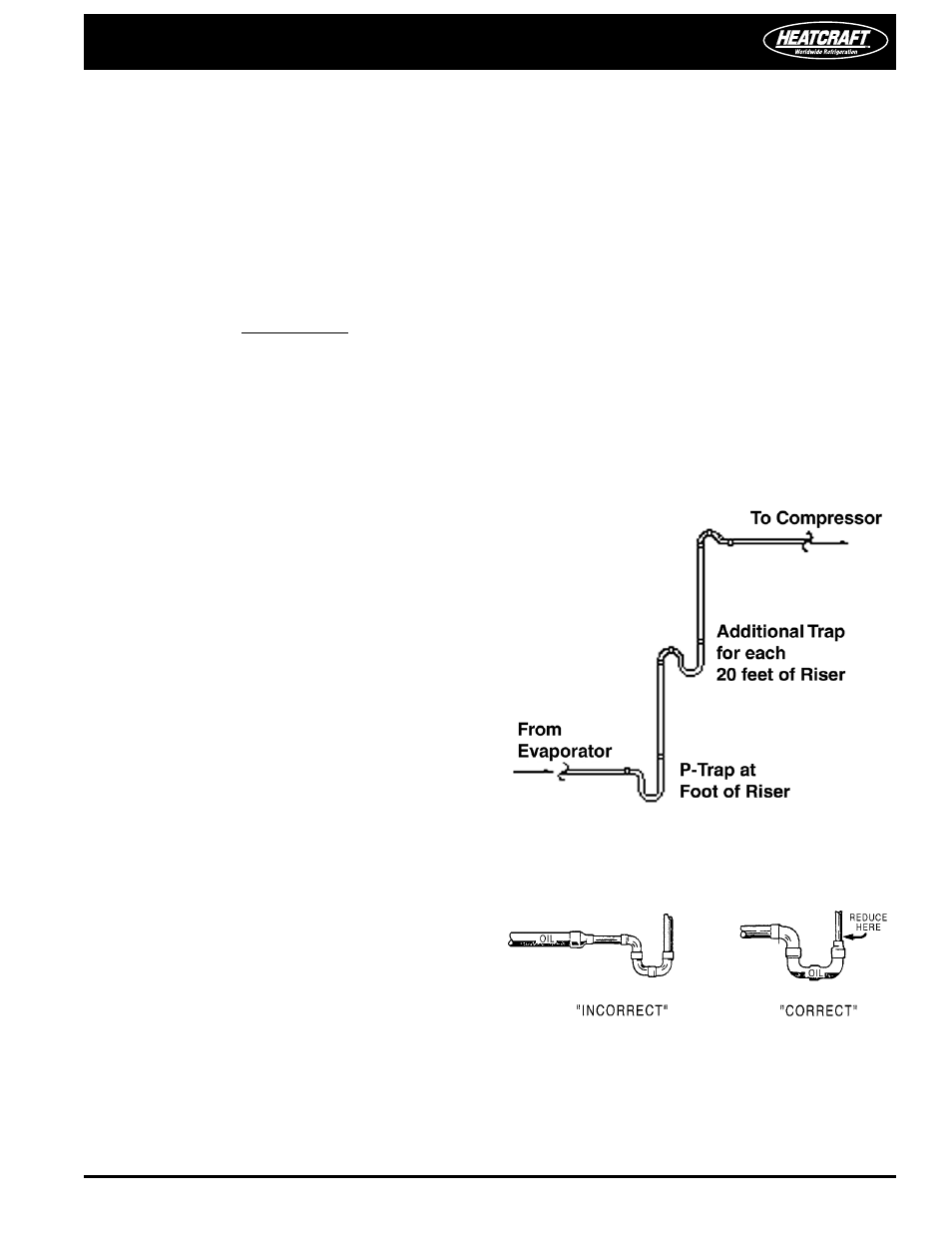

• Provide P-Traps at the base of each suction riser of four (4)

feet or more to enhance oil return to the compressor. Use a

P-Trap for each 20 feet section of riser. See Figure 4 below:

*The P-Trap should be the same size as the horizontal line

See Figure 5 below

Parallel Compressor Systems

Figure 4. P-Trap Requirements

Figure 5. P-Trap Construction