Vent information and diagrams, Warning – Hearth and Home Technologies GATEWAY User Manual

Page 15

Heat & Glo • Gateway • 288-900 Rev. W • 10/08

15

5

5

Vent Information and Diagrams

Fire Risk.

Asphyxiation Risk.

This appliance requires the specifi ed pipe for

operation.

• Incorrect pipe may cause spillage, condensation

and overheating.

WARNING

Fire Risk.

Explosion Risk.

Venting parameters must not be exceeded.

This gas fi replace must never be vented by

connecting to a chimney fl ue serving a separate

solid fuel burning appliance.

WARNING

Model GATEWAY is approved to use Duravent 4-inch (102

mm) diameter B-type vent for installations that terminate

vertically. The PV-Flex Series vent pipe is approved for

use in installations that terminate horizontally. This pipe

is tested and listed as an approved component of the

fi replace.

This model may also use single wall rigid or fl exible gas

vent IF and ONLY IF the vent system is installed within

non-combustible construction such as a masonry chim-

ney. The same diameter noted above for B-type vent

must be used for single-wall vent (see Figure 5.1).

For B-type vent the clearance to combustibles is 1-inch all

around the pipe. Follow vent manufacturers REQUIRED

clearances. For PV-Flex the clearances are 1-1/2 in. top

and 1 in. sides and bottom when venting horizontally

and 1 in. on all sides when passing vertically through

combustible materials.

A. Vent System Approvals

Vent pipes must be installed within the conditioned house

envelope in order to avoid fl ue gas condensation. Verti-

cal termination through an unconditioned attic space is

permissible.

The fl ame and ember appearance may vary based on the

type of fuel burned and the venting confi guration used.

NOTE: Due to the positive pressure within the Gateway

venting system, when using PV-FLEX use a 1/2 in. bead of

HIGH TEMPERATURE silicone caulk on ALL pipe ends and

connectors throughout the vent run to ensure a completely

sealed system.

No. of 90º

Elbows/ Bends

Maximum

Vertical Run

Maximum

Horizontal Run

Maximum

Total Run

0

-

40’ (12.2 m)

40’ (12.2 m)

1

50’ (15.2 m)

-

50’ (15.2 m)

1

-

35’ (10.7 m)

35’ (10.7 m)

2

-

35’ (10.7 m)

35’ (10.7 m)

2

35’ (10.7 m)

35’ (10.7 m)

38’ (11.6 m)

3

30’ (9.1 m)

35’ (10.7 m)

35’ (10.7 m)

4

25’ (7.6 m)

32’ (9.8 m)

35’ (10.7 m)

5

25’ (7.6m)

30’ (9.1 m)

33’ (10.1 m)

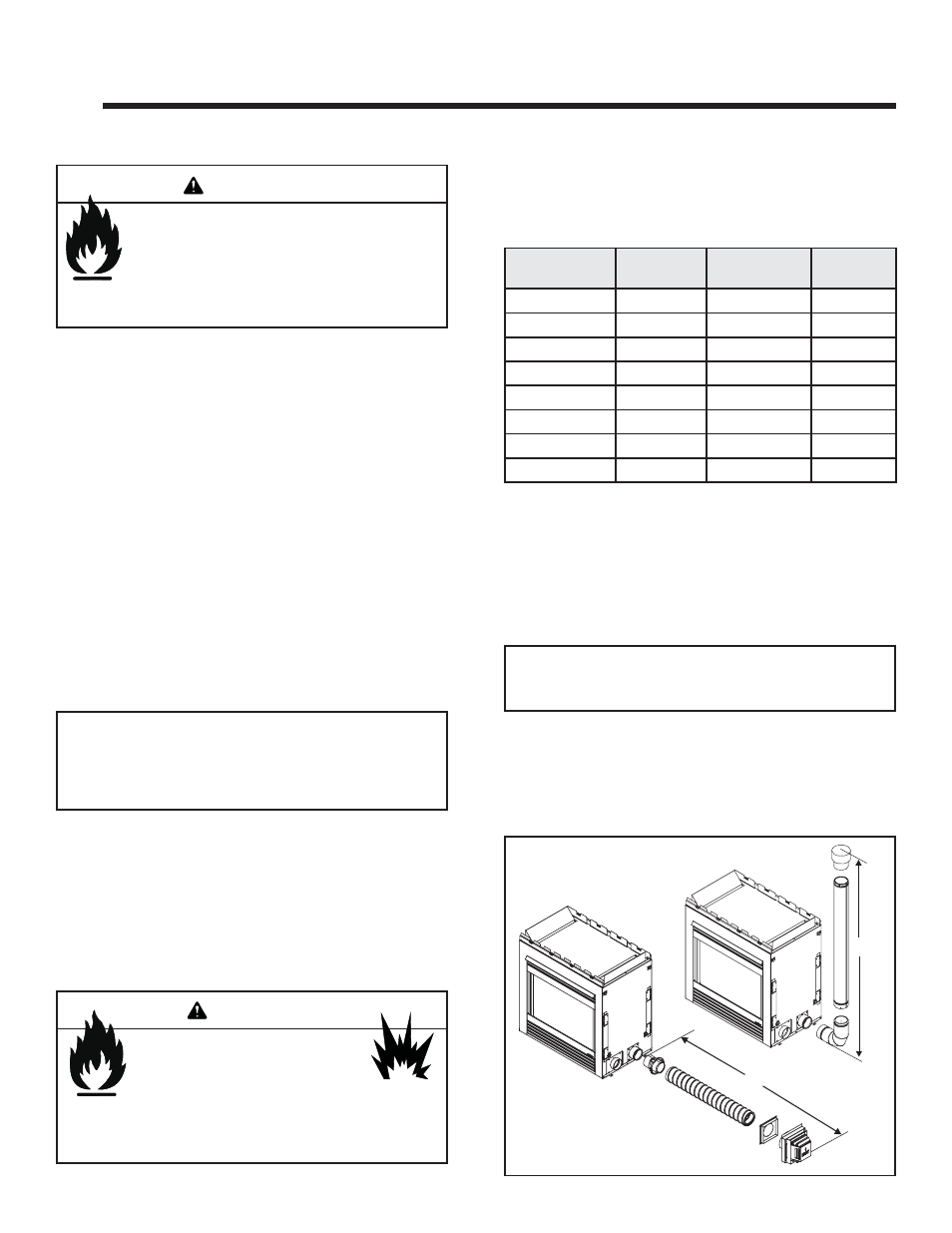

Figure 5.1 Vent System Attachment

The following fi gures are examples of approved venting

conditions. Venting downward (3 feet maximum) is ap-

proved, to allow venting below the fl oor. However, only

one downward section is allowed for up to, but not ex-

ceeding 3 feet maximum.

Maximum Total Run: = 50 FT.

Maximum No. Of Elbows/bends: fi ve - 90º or ten - 45º

50 FT.

40 FT.

B. System Components

Consult Local Building Code Offi cials and Codes for

proper vent system installations.

Plan and install the vent system using the parameters

shown in this vent system confi guration chart.

Continue to add vent components, until the vent run is

completed.

See Section 8 for instructions regarding assembly of vent

sections and securing vent sections.

Note: It is always better to fi rst attach a straight section of

vent to the unit before attaching an elbow. Avoid using elbows

in the vent system if possible.