Palsun® technical guide – Palram PALSU User Manual

Page 35

PALSUN® Technical Guide

35

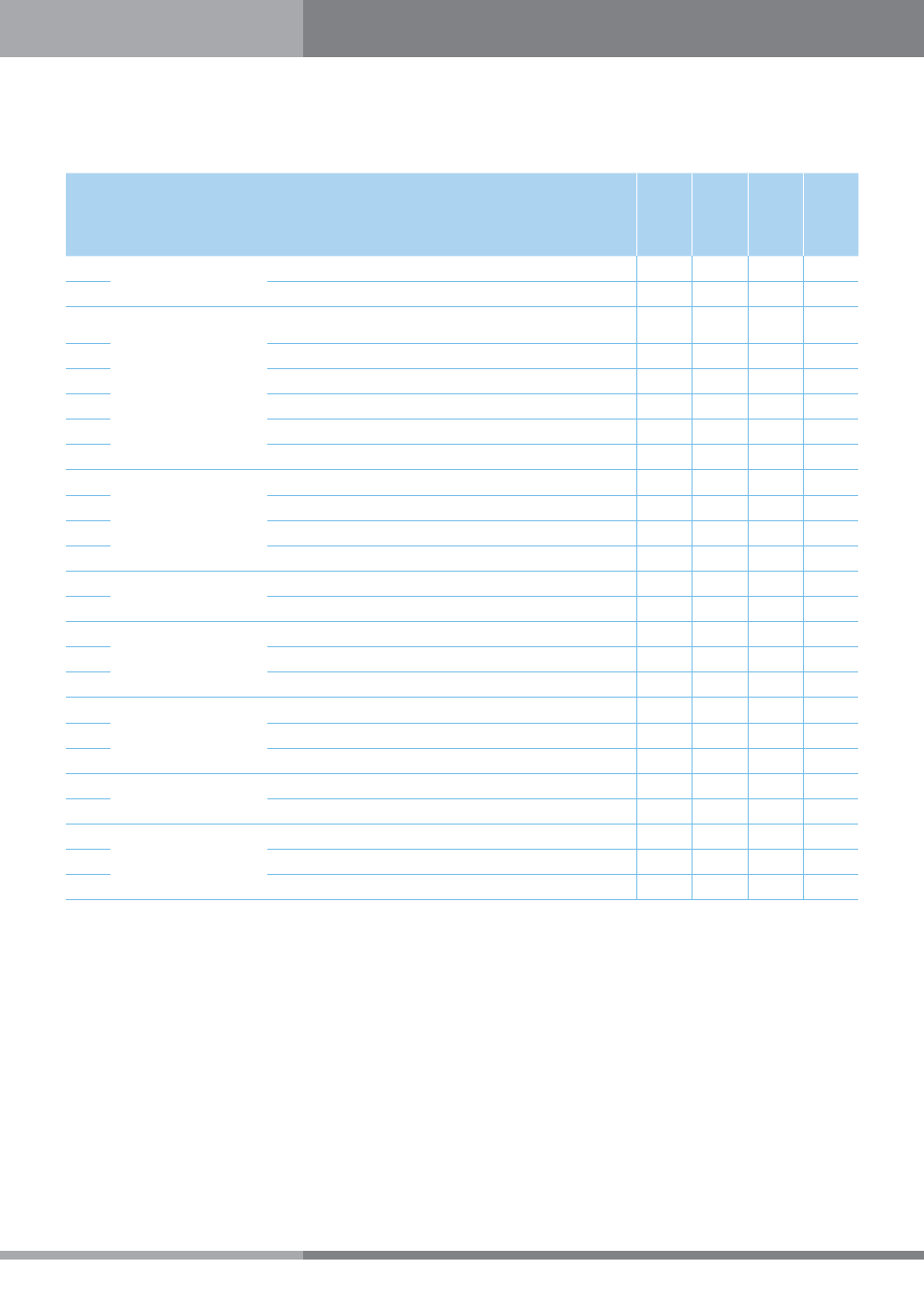

Fault and Remedies in Thermoforming Practice

#

Recognized Fault

Probable Cause

Proposed Treatment

Hot Line

Bending

Dr

ape

For

ming

Vacuum

For

ming

Fr

ee

Blo

wn

1

Bubbles in sheet

Moisture content too high

Pre-drying

+

+

+

+

2

Working temp. too high

Decrease working temp.

+

+

+

3

Hair fissures, fragile parts

Part overheated

Decrease heating period

+

+

4

Mold under-heated

Increase mold temp.

+

5

Late extraction of part

Diminish cooling cycle

+

6

Vacum speed too high

Reduce vacum rate

+

7

Mold corners too sharp

Round sharp corners

+

8

Basic sheet size too small

Increase sheet size

+

9

Webbing

Erratic heating

Prevent hot or cold spots

+

10

Mold lead inadequate

Check spacing-min. depth x 2

+

11

Vacum speed too high

Reduce vacume rate

+

12

Basic sheet size too large

Clamp/mold spacing <50mm

+

13

Blurred or partial detailing

Vacum too weak

Seal leaks/add vacum holes

+

14

Sheet rigid, under-heated

Extend heating period or temp.

+

15

Product sticks to mold

Mold overheated

Decrease mold temperature

+

16

Product release delayed

Shorten release period

+

17

Draft angle too steep

Enlarge draft angle up to 4-6°

+

18

Marked zones on product

Irregular finish of mold

Treat mold to consistent finush

+

19

Suction holes misplaced

Install new, better placed holes

+

20

Sheet overheated

Decrease heating period/ temp.

+

+

21

Exterior flaws / roughness

Dirt/ grime on sheet / mold

Wipe/Vacum-clean mold/sheet

+

+

22

Suction holes misplaced

Install new, better placed holes

+

23

Inconsistent shape of part

Mold/ brace under-heated

Extend pre-heat of mold/brace

+

24

Irregular heating/ cooling

Prevent drafts, fix faulty heater

+

+

+

+

25

Product release delayed

Shorten release period

+