Palram PALSU User Manual

Page 26

26

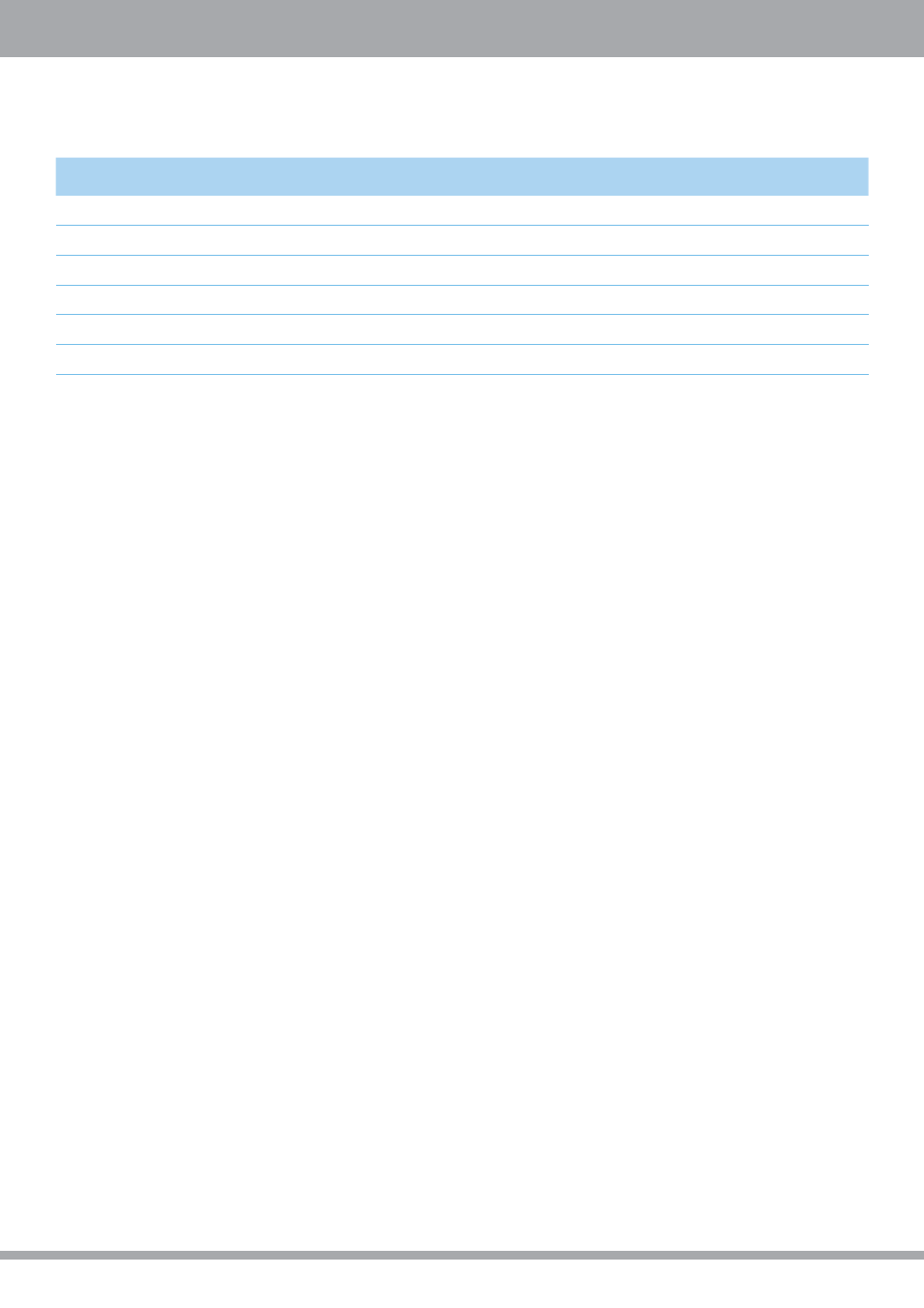

Recommended Band Saw blade Properties

Property

Sign

Units

Value

Clearance angle

α

10 – 20°

Rake angle

γ

5 – 15°

Cutting speed

m/min (ft/min)

1,000 - 6,000 (1,950 - 3,300)

Rate of feed

mm/sec (inch/sec)

20 (13/6)

Thin gauge: 1.5-2.5 mm tooth pitch (1/16” - 3/36” )

t

Teeth per mm (Teeth per in.)

1.5 - 2.0 (12 - 18)

Heavy gauge: 3.2 - 12 mm tooth pitch (1/8” - 1/2” )

t

Teeth per mm (Teeth per in.)

2.5 - 3.5 (7 - 10)

Notes:

1. A band saw is suitable for cutting curved lines and 3-dimensional, formed parts.

2. For cutting a few formed objects of the same shape, they must be firmly clamped together.

3. A band saw cutting usually yields rougher finished edge, which must be smoothed by sanding and polishing.

An endless belt sander is a preferred tool for such an operation.

4. Palram recommends using a circular saw for better-finished edges, whenever possible.

Portables: Jigsaw or Saber Saw

Portable saws of these types use short movement, reciprocating blades, instead of one-direction orientation, continuous

movement blades like those of circular or band saws, and are much slower in operation.

Chipping: Various sized chips are broken off on both edges of the sawing line, leaving the cut edges rough and uneven.

Gumming: Chips and splinters from the advancing saw blade overheat during the sawing process, melt and create a mass of

cooled down material in front of the blade and on both sides of the cut. The swarf sticks to the edges, leaving an unsightly, rough

edge finish, which would be difficult to clean.

Jigsaw or saber saw cutting usually results in an inferior finish of the cut edges, worse than the results achieved by a circular

saw. Palram recommends sanding and polishing of the cut edges as standard practice. An endless belt sander is the preferred

tool for such an operation.

Gummed material may also stick to the blade itself and cause seizure.

The same uncontrolled heat that creates gumming may also induce undue internal stresses along the edges of the cut,

necessitating cooling of the sheet.

Recommended Remedies:

Choose the correct tooth size and pitch.

Select a more appropriate saw speed.

Lower the feed rate.

Examine the sharpness of the blade.

Examine the blade alignment.

Cool the blade with compressed air when long cuts are required.

Take frequent pauses during long production runs, to let the saw blade cool down.

Begin sawing with the blade already running at the full recommended speed.