Trouble shooting chart, Trouble shooting points – Sears 358.79828 User Manual

Page 26

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

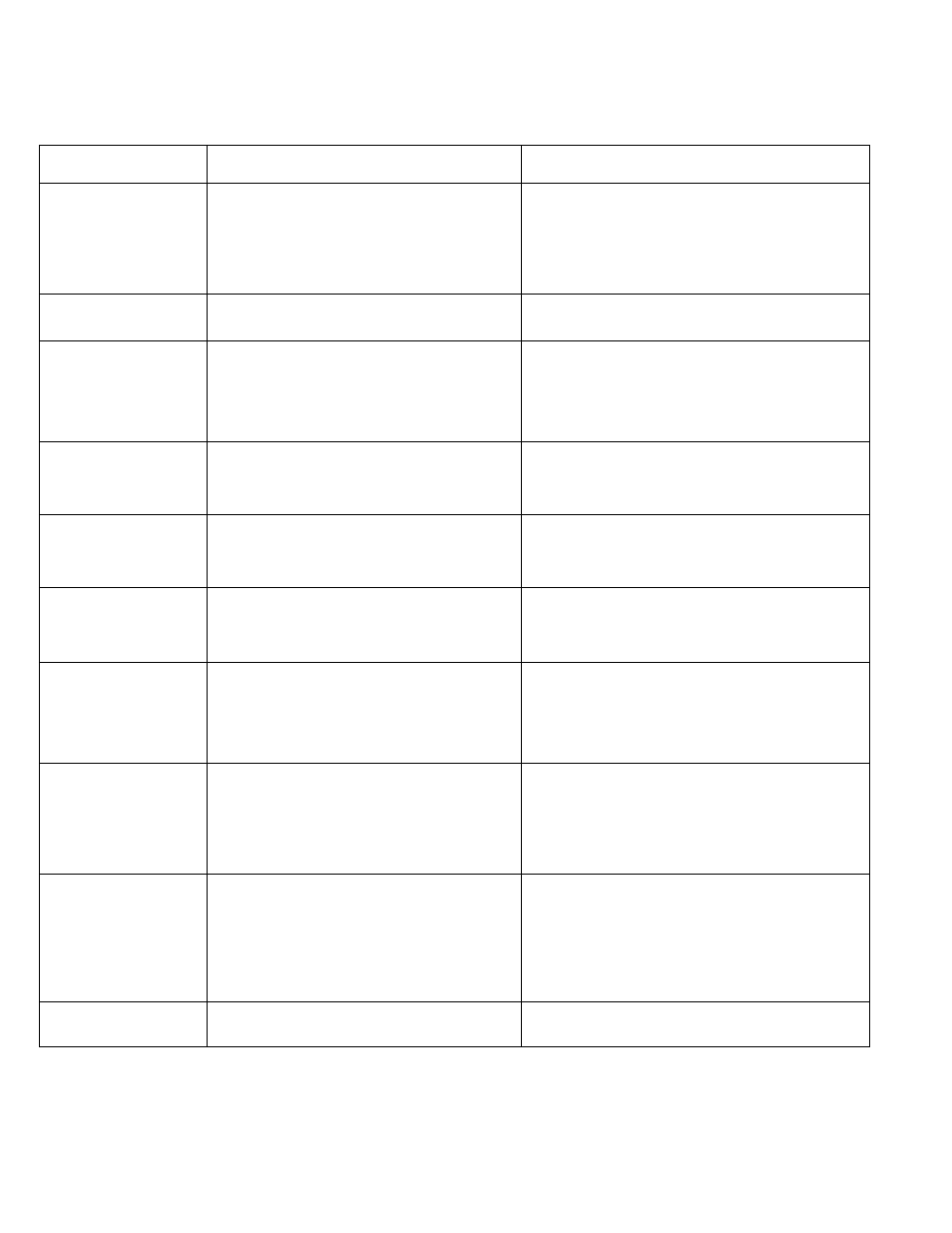

TROUBLE SHOOTING POINTS

TROUBLE SHOOTING CHART

SYMPTOM

CAUSE

REMEDY

Engine will not start

or will run only for

a few seconds

after starting.

1. Engine switch on stop.

2. Fuel tank empty.

3. Engine flooded.

4. Spark plug not firing.

5. Fuel not reaching cailjuretor,

6. Carburetor requires adjustment.

1. Move switch to on position.

2. Fill tank with correct fuel mixture

3. See “Starting Instructions."

4, Install new plug/check ignition system.

5, Clean fuel filter; inspect fue! line.

6, See “Carburetor Adjustments/ :

Engine will not idle

properly.

1. Air fitter is dirty,

2. Carburetor requires adjustment

1. Clean air filter.

2. See “Carburetor Adjustments."

Engine will not

accelerate,lacks

power, or dies

under a load.

t. Air fitter dirty.

2. Spade plug fouled. -

3. Carburetorreqoires adjustment ■

4. Muffler outlets plugged-or spark arrestor-

screen obstructed: ................................

1. Clean or replace air filter.

2. Clean or replace spatk plug and re-gap.

3. See “Carburetor Adjustments.”

4. See “Inspect Muffler and Spark Arrestor

Screen."

Engine

smokes

excessively.

1. Air fitter dirty.

2. Fuel mixture incorrectAbo much oil.

3. Carburetor requires adjustment

1. Clean or replace air filter.

2. Reftjel with correct fuel mixture.

3. See “Carburetor Adjustments.”

Engine runs hot.

1, Fuel mixture incorrect

2. Spark plug incorrect.

3- Carburetor requires adjustment

1. See “Before Fueling Engine."

2. Replace with correct plug.

3. See “Catburetor Adjustments.”

Cutting attachment

turns at idle speed.

1. Carburetor requires adjustment.

2. Throttle cable binding.

3. Clutch requires repair.

1. See “Carburetor Adjustments.”

2. Contact your Sears Service Center.

3. Contact your Sears Service Center.

Cutting attachment

stops under a load

or does not turn

wrtien engine is

acxelerated.

1. Carburetor requires adjustments.

2. Drive shaft broken.

3. Clutch requires repair.

1. See “Carburetor Adjustments."

2. Contact your Sears Service Center.

3. Contact your Sears Service Center.

Line does not

advance or breaks

while cutting.

1. Line, improperly routed in head.- ..

2. Line improperly wound onto.spooL

3. Line size incorrect

4. Dirt accumulated on cover cut-outs: ■

5. Line is too old.

1. Remove cover. Check line routing.

2. Rewind line tightly and evenly

3. Use only .095" gwxJ quality monofilament line.

4. Glean cover cut-outs.

6. Install new line using ,095" good quality

monofilament line.

Line welds on

spodl/metts to-

gather

1. Line size incorrect.

2. Incorrect spool.

3. Line improperly wound onto spool.

4. Crowding line against material being cut.

5. Cutting at higher speed than necessary

6. Line is too old-

1. Use only .095 good quality monofilament line.

2. Use proper spool.

3. Rewind line tightly and evenly.

4. Cut with tip of line.

5. Reduce cutting speed.

6. Install new line using .095” good quality

monofilament line. .

Line pulls back

into head.

1. Too little line outside of head.

2. Line size incorrect.

1. Remove cover. Pull 4” of line to outside.

2. Use .095" good quality monofllament line.

If situations occur which are not covered in this manuai, use care and good judgement.

If you need assistance, contact your SEARS Sendee Center/Department or the

CUSTOMER ASSISTANCE HOTLINE at 1-600-235-5878.

- 2 6 -