Ieck for loose fasteners/parts, Cck gear box lubrication 29 ), Ean air filter (fig. 30 ) – Sears 358.79828 User Manual

Page 21: Replace spark plug (fig. 31 ), Inspect muffler and, Spark arrestor screen (if installed), Customer responsîbiuties

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

CUSTOMER RESPONSÎBIUTIES

iECK FOR LOOSE FASTENERS/PARTS

Blade Nut

Dual Line Head Nut

Handlebar, Mounting Bracket, and Thumb Screw

Throttle Handle

Minder Cover/Muffler Guard

itir Filter Cover

Muffler

Searbox

CCK GEAR BOX LUBRICATION

29 )

Jltnally ft is rtot necessary to change the grease except

!fing service of the gearbox assembly

Remove the gearbox plug to check the grease level.

Grease level should be 3/4 full. Use a general purpose

lithium base grease.

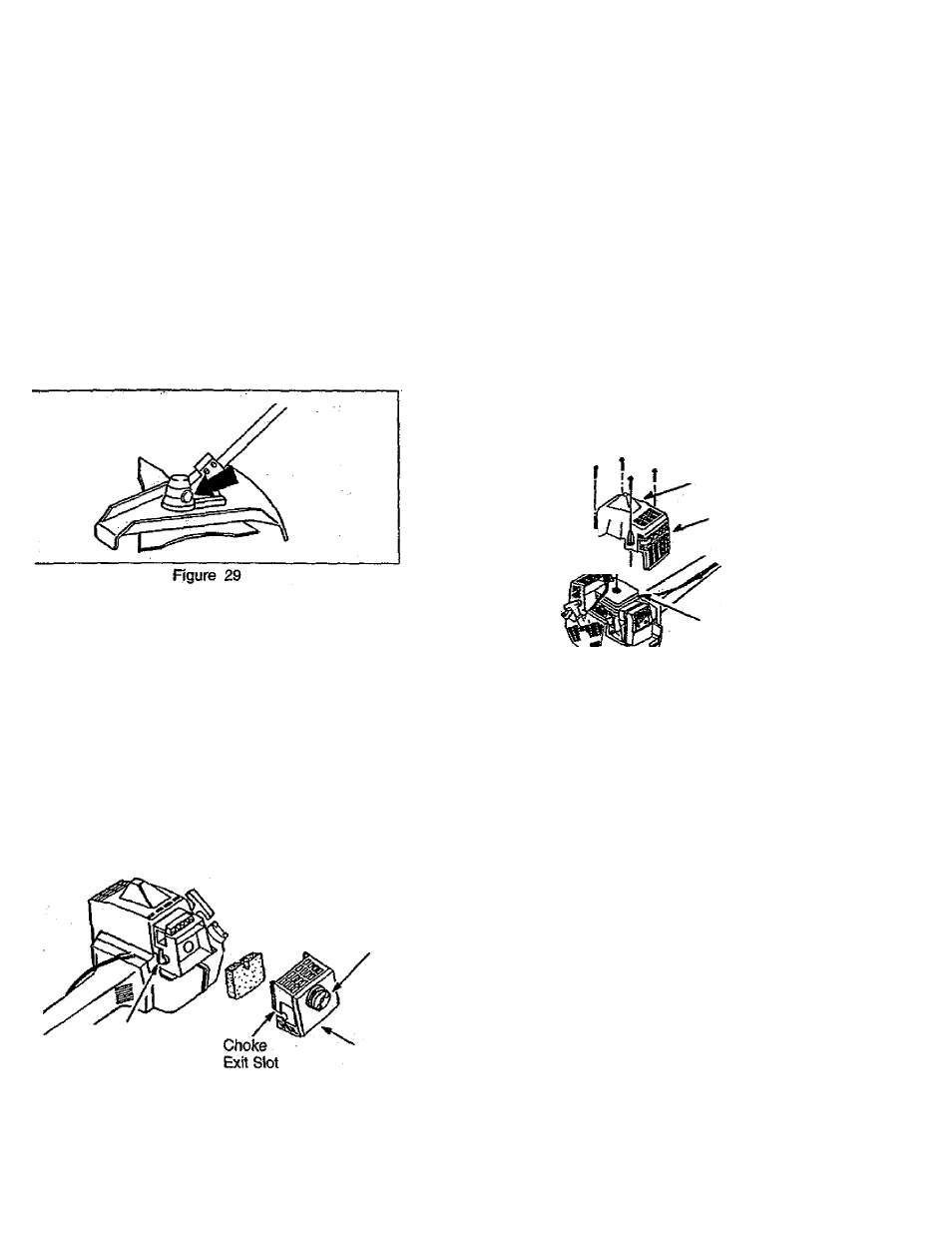

EAN AIR FILTER (Fig. 30 )

Itrty air filter decreases the life and performance of the

line and increasesfuel consumption and harmful emis*

is.

■ ,

_ ■ ■ '

(ays clean after 5 tanks of fuel or 5 hours of operation,

chever is less. Clean more frequently in dusty condi-

œ.

Loosen the screw on the air filter knob enough to re-

nrove the cover from the engine,

l^emove air filter from cover.

Wash air filter in soap and water.

Squeeze air filter dry and replace in cover, .

Reinstall the air filter cover, making sure the choke exit

slot is placed over the choke lever.

Air Rller

^ Air Rlter Knob

Choke Lever

Cover

REPLACE SPARK PLUG (Fig. 31 )

The spark plug should be replaced each year to ensure ffie

engine starts easier and njns better.

Spark Plug gg^ should be .020".

• Loosen 4 screws from cylinder cover vwth hex key.

Remove cylinder cover.

• Pull off the spark plug boot

• Remov® and discard the spark plug from the cylinder.

• Replace with correct spark plug and tighten with blade

nut/spafk plug wrendi (10-12 Ib-ft),

• Cover spark plug with spark plug boot

•

B^lace the cylinder cover making sure the muffler

.... guard interlocks with the crank case assembly. Insert 4

screws and tighten securely.

Screws

Spark Plug.__ f

Spark Plug Boot

Cylinder Cover

Muffler Guard

Cylinder

Figure 30

Figure 31

INSPECT MUFFLER AND

SPARK ARRESTOR SCREEN (IF INSTALLED)

As the unit is used, carbon deposits build up on the muffler

and spark arrestor screen (if installed), and must be re

moved to; avoid creating a fire hazard or affecting engine

performance.

Required cleaning is every 10 hours of operation.

Replace the spark arrestor screen if breaks occur.

CLEANING THE SPARK ARRESTOR SCREEN

• Di$(x>nnect the spark plug wire.

.

• Remove the spark arrestor screen. (Referto the Spark

Arrestor Screen Assembly section of this manual).

• Clean the spark arrestor screen with a wire brash or re

place if breaks are found in the screen.

•

Reassemble parts. (Refer to the Spark Arrestor

Screen Assembly section of this manual).

- 2 1 -