Carburetor presets (fig. 39), Adjusting procedure, Idle speed adjustment – Sears 358.79828 User Manual

Page 24: Low speed mixture adjustment, High speed mixture adjustment, Acceleration check, Service and adjustments, Carburetor adjustments

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

SERVICE AND ADJUSTMENTS

CARBURETOR ADJUSTMENTS

Carburetor adjustment is critical and if done improperly can permanently damage the engine as well as the car

buretor. Please read all instructions and consult the Troubleshooting section of this manual before beginning

this process.

If engine does not start, it may be flooded. If in doubt,

read the section on flooded engine in the starting section

of this manual prior to beginning any adjustments.

If you are unsure about adjusting the carburetor or expe

rience any problem while attempting this process, please

call the 1-800 number listed on the front cover of this

manual for further assistance.

The carburetor has been adjusted at the factory for sea

level conditions. Adjustments may become necessary if

the unit is used at significantly higher altiftjdes or if you

notice any of ttie follovring conditions:

• Blade or trimmer head moves when the engine runs at

idle speed. See “Idle Speed Adjustment”

• Engine will not idle. See “Idle Speed Adjustmenf and

. “Low Speed Mixture Adjustment*

• Engine dies or hesitates when it-should accelerate; See

“Acceieration Adjustment”

• Loss of cutting power which is not corrected by air filter

. deanfng. See “High Speed Mixture Adjustment”

NOTE: If the Cutting Attachment rotates during idle, turn

the idle speed adjuring screw (T") counterclockwise unh'l

the Cutting Attachment stops.

A

CAUTION:

MAKE

ALL

CARBURETOR

ADJUST

MENTS WITH TRIMMER HEAD ATTACHED.

BaNOT ATTEMPTTO ADJUST CARBURE

TOR WITH BLADE ATTACHED DUE TO DIF

FICULTY OF PROPERLY SETTING CARBU

RETOR.

SEVERE

ENGINE

DAMAGE

COULD OCCUR.

A

WARNING:

MAKE

CARBURETOR

ADJUSTMENTS

WITH THE LOWER END SUPPORTED TO

PREVENT TRIMMER HEAD FROM CON

TACTING ANY OBJECT. HOLD UNIT WITH

YOUR HAND.

THE TRIMMER HEAD WILL BE SPINNING

DURING MOST OF THIS PROCEDURE.

WEAR YOUR PROTECTIVE EQUIPMENT AND

OBSERVE ALL SAFETYiERECAOTIONS,

IN “LOW SPEED MIXTURE ADJUSTMENT,^

RECHECK

IDLE

SPEED

AFTER

EACH.

ADJUSTMENT.THETRIMMER

HEAD

MUST

NOT MOVE AT IDLE SPEED.

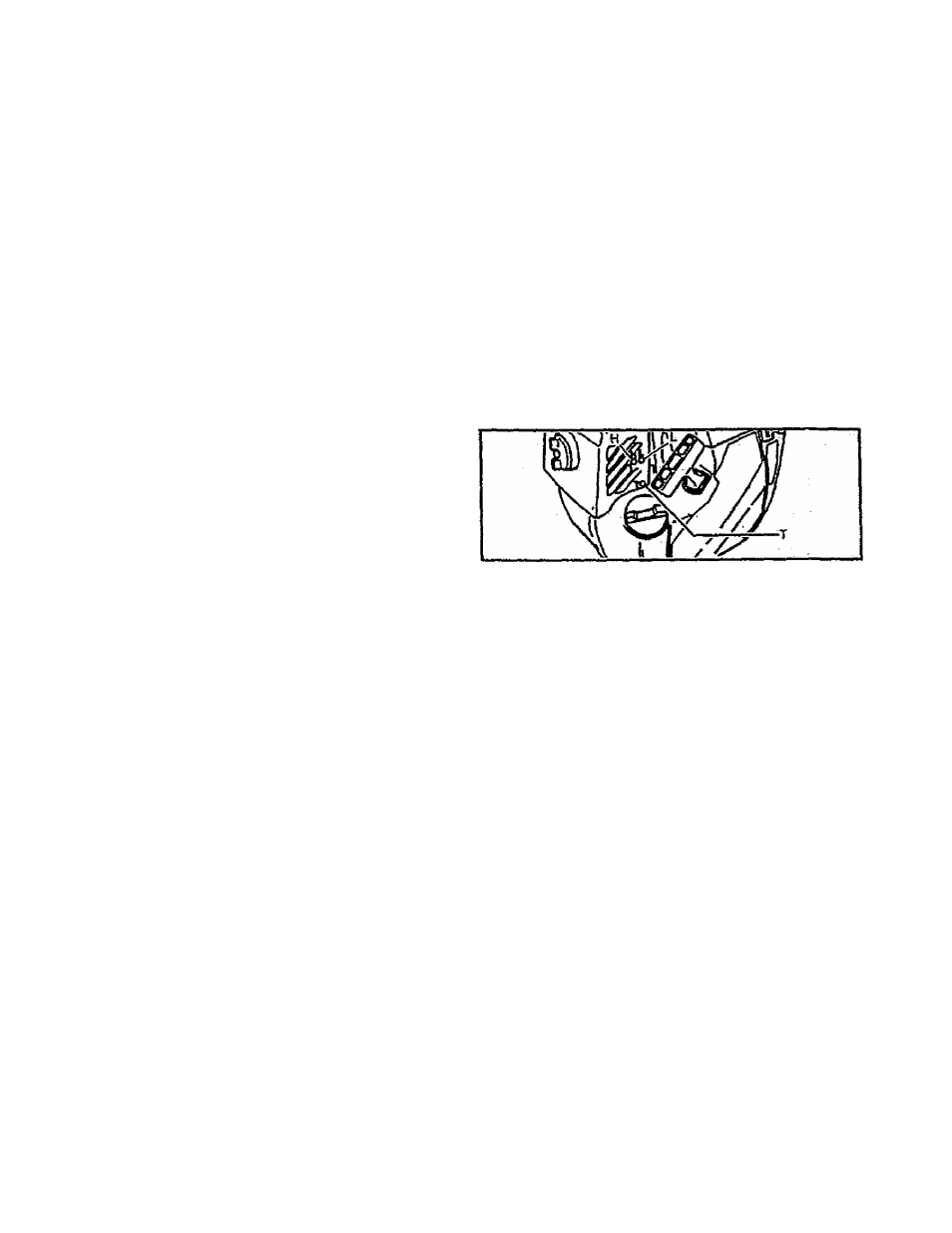

CARBURETOR PRESETS (Fig. 39)

The Carburetor has three adjusting screws:

L = Low speed mixture adjusting screw

H =: High speed mixture adjusting screw

T = Idle speed adjusting screw

If your engine will not start due to suspected improper car

buretor adjustment, the following presets may be required.

If used, it is recommended that all steps vri&iin the adjust

ment procedure be completed in order to assure a prop

erly set carburetor. If presets are not needed, proceed to

section “Idle Speed Adjustment.”

Very small adjustments can affect engine performance. It

is mportant to turn the screw a very small amount per

adjustment and test performance before making further

adjustments. Each adjustment should be no more than

the width of the slot in the adjusting screw.

• Turn both of the mixture screws (marked "H” and “L”)

- clockwise until they stop. Do not force the screws as

damage can occur. Then, turn each screw one (1) full

turn counterclockwise.

• Turn idle speed screw (“T”) clockwise 1/2 turn.

• Start the engine and operate tor ten (10) minutes to

warm up. Go to "Adjusting Procedure.”

ADJUSTING PROCEDURE

Engine operating speeds: Maximum operating speed:

11,000 RPM.

IDLE SPEED ADJUSTMENT

• Allow the warm engine to idle.

• Adjust the Idle Speed Screw until the engine continues

to run without stalling and without the blade or serni-

automatic head turning,

- Turn screw clockwse to increase engine speed if

0nntn^

cte/te

- Turn screw counterclocdtwise to stow engine down

and/orto keep the Nade-OrtrMnerheadtojm.tunv^.

• No further adjustments are necessary if blade or trim

mer head does not turn at idle speed and if perfor

mance is satisfactory.

Figure 39

LOW SPEED MIXTURE ADJUSTMENT

• Allow engine to idle.

• Turn the Low Speed Mixture Screw slovyiy clockwise

until the RPM Starts to drop. Note fr)e position.

• Turn the Low Speed Mixture Screw slowly counter

clockwise until the RPM speeds up and starts to drop

again. Note the position.

• Set the Low Speed Mixture Screw at the midpoint

between the two positions.

HIGH SPEED MIXTURE ADJUSTMENT

IMPORTANT-.DO NOT OPERATE ENGINE AT FULL

THROTTLE POR PROLONGED PERIODS WHILE

MAKING HIGH SPEED ADJUSTMENTS AS DAMAGE

:TQ.THE ENGINE CAN OCCUR.

> . Make a test cut in grass.

• Based on performance of the unit while cutting, adjust

the high speed mixture screw in 1/16 turn increments

as follows:

- Clockwise if unit smokes or loses power wij/te cuttíng.

Do not adjust for best power by sound or speed, but

- judge by how well the unit performs during operation.

- Counterdockwise if the unit has speed while not cut

ting, but dies or lacks power while cutting.

• Repeat the test cut in grass.

• Continue with 1/16 turn adjustments until the unit per

formance is acceptable while cutting.

• After completing adjustments, check for acceieration,

• If unit accelerates properly no further adjustments are

necessary. If not proceed to acceleration check.

ACCELERATION CHECK

• If the engine dies or hesitates instead of accelerating, krm

the Low Speed Mixture Screw 1/16 of a turn at a time

cduntenciockwise until you have smooth acx»(eration.

• Check the idle speed for stability and that the blade or

trimmer head does not turn. Adjust as necessary.

• Recheck for smooth acceleration and stable idle.

• Repeat process as necessary for acceptable perfor

mance.

- 2 4 -