Maintenance, Lubrication, Reyoving pulley cover and installing drive belt – Sears 113.22643 User Manual

Page 19

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

maintenance

WARNiNG: For your own safety, turn switch “OFF”

and remove plug from power source outlet before

adjusting, maintaining, or

lubricating your belt and

disc

Sander.

WARNING: To avoid electrocution or fire, any re

pairs to electrical systems should be done only by

qualified service technicians. Unit must be reas

sembled exactly to factory specifications.

If powercord is worn or cut, or damaged in anyway, have

it replaced immediately.

Frequently blow out or vacuum out any dust that may

accumulate inside the motor.

A coat of automobiie-type wax applied to the worktable

will make it easier to feed the work while finishing.

Do not apply wax to the abrasive belt table because the

belt could pick up the wax and deposit it on the pulleys,

causing the belt to slip.

LUBRICATION

The BALL BEARINGS in this machine are packed with

grease at the factory. They require no further lubrication.

Sleeve bearings should be lubricated with 30 weight oil

or equivalent after each 10 hours of operation.

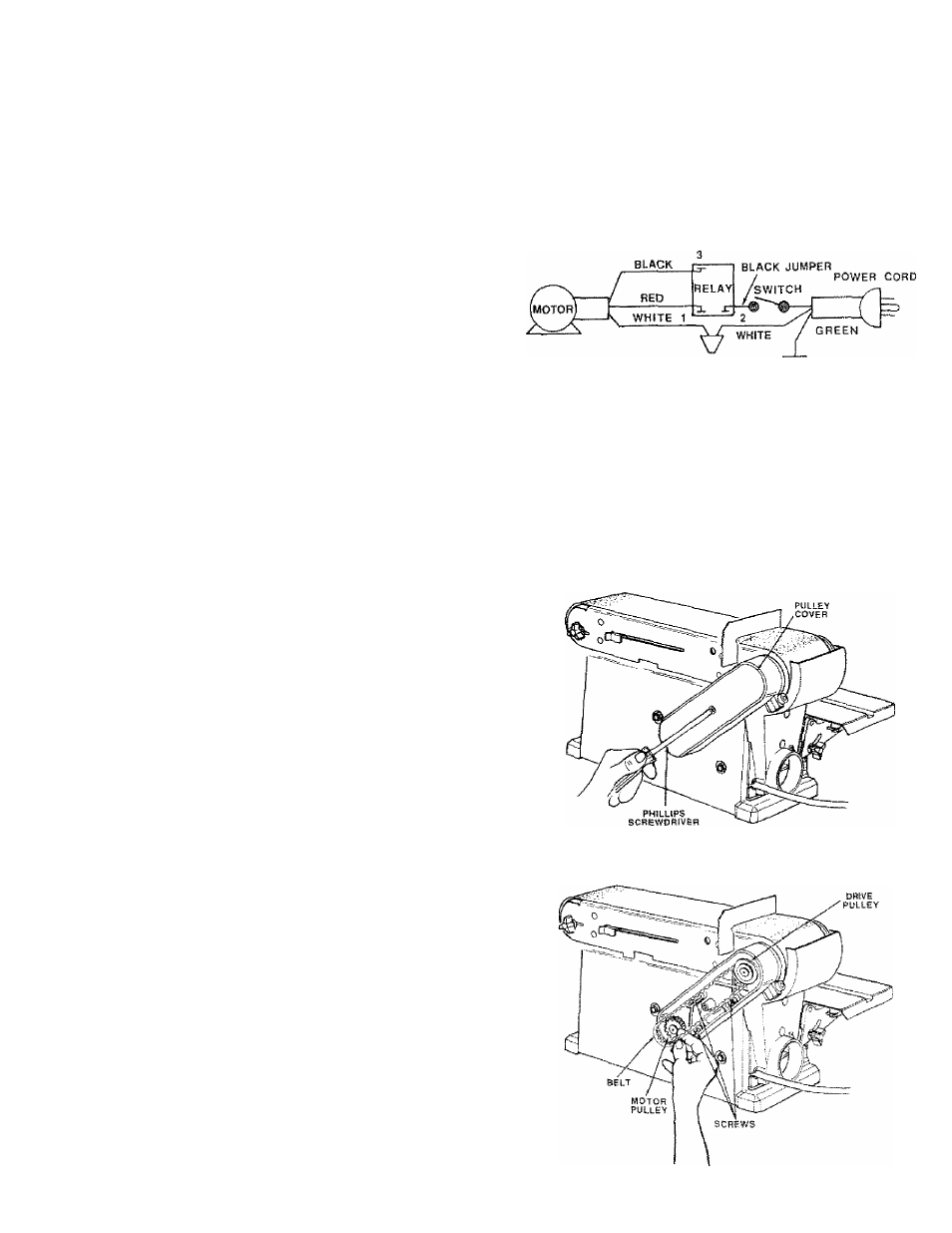

WIRING DIAGRAM

REyOVING PULLEY COVER AND

INSTALLING DRIVE BELT

1. Using a Phillips screwdriver, remove the flat head

screw located in the middle of the cover.

2. Remove the cover.

3. Loosen (3) screws to allow pulleys to shift enough to

place belt around them. Place belt around motor

pulley and drive pulley as shown if belt is ever broken.

19