Troybie shooting – Sears 113.21308 User Manual

Page 23

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

troybie shooting

WARNING; FOR YOUR OWN SAFETY, TURN SWITCH "OFF" AND ALWAYS REMOVE PLUG FROM POWER

SOURCE OUTLET

BEFORE TROUBLE SHOOTING.

• CONSULT YOUR LOCAL SEARS SERVICE CENTER IF FOR ANY REASON MOTOR WILL NOT RUN.

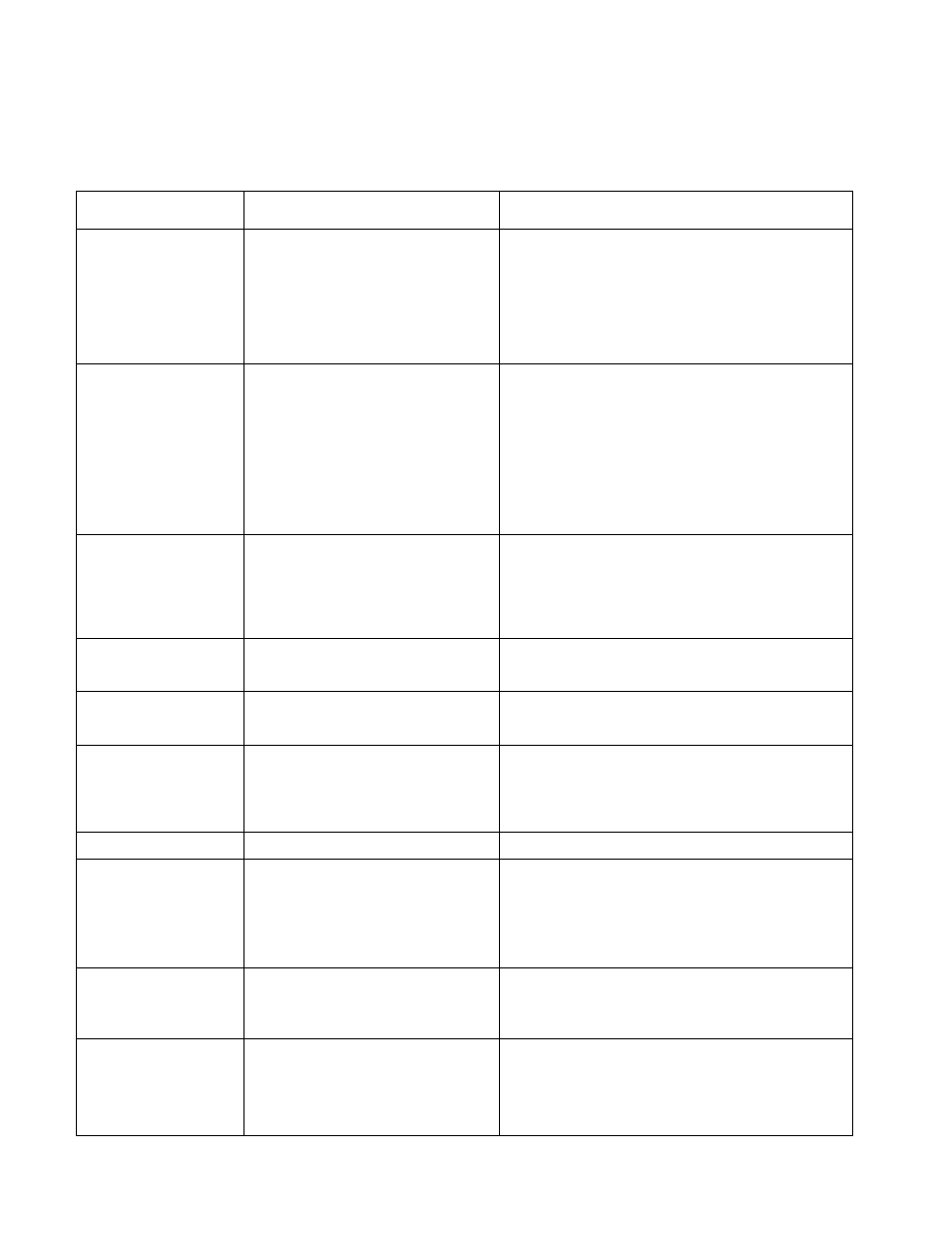

TROUBLE

PROBABLE CAUSE

REMEDY

. . ...............

Noisy Operation

j

1

. Incorrect belt tension,

2. Dry Spindle,

3. Loose spindle pulley,

4. Loose motor pulley.

1. Adiust tension. See section

' "ASSEMBLY-TENSIONING BELT."

2, Lubricate spindle. See “Lubrication"

section.

3. Checking tightness of retaining nut on

pulley, and tighten if necessary.

4, Tighten setscrews in pulleys.

Drill Burns

1. Incorrect speed,

2. Chips not coming out

of hole.

3. Dull Drill.

4. Feeding too slow,

5. Not lubricated.

1, Change speed. See section “Getting

To Know Your Drill Press".,,

DRILLING SPEED.

2, Retract drill frequently to clear chips.

3, Resharpen drill.

4, Feed fast enough ,, , allow drill to cut.

5, Lubricate drill. See “Basic Drill Press

Operation" section.

1 Drill leads off...

1 hole not round.

1, Hard grain in wood or

lengths of cutting

lips and/or angles

not equal.

2. Bent drill bit.

1. Resharpen drill correctly,

2. Replace drill bit.

Wood splinters on

underside.

1. No “back-up material’'

under workpiece.

1. Use “back-up material",., See Basic

Drill Press Operation" section.

Workpiece torn

loose from hand.

1. Not supported or

clamped properly.

1. Support workpiece or clamp it... See

“Basic Drill Press Operation" section.

Drill Binds in

workpiece.

1. Workpiece pinching drill

or excessive feed pressure.

2. Improper belt tension.

1. Support workpiece or clamp it... See

“Basic Drill Press Operation" section.

2. Adjust tension .,. See section

“ASSEMBLY-TENSIONING BELT."

Excessive drill

1. Bent drill.

1. Use a straight drill.

runout or wobble.

2. Worn spindle bearings.

3. Drill not properly

installed in chuck.

4. Chuck not properly installed.

2. Replace bearings,

3. Install drill properly... See “Basic

Drill Press Operation" section.

4. Install chuck properly.,. refer to

“Unpacking and Assembly Instructions

. ,. INSTALLING THE CHUCK,"

Quill Returns

too slow or too

fast.

1. Spring has improper tension.

1. Adjust spring tension .,. See section.

“Adjustments—Quill Return Spring.”

Chuck will not stay

attached to spindle

it falls off when

trying to install it.

1. Dirty, grease, or oil on the

tapered inside surface of chuck-

oronthe spindles tapered

surface.

1. Using a household detergent-dean the

tapered surface of the chuck and spindle to

remove a!i dirt, grease and oil

o>

8

Jtz

m

m

23