Hole location, Feeding, Adjustments – Sears 113.21308 User Manual

Page 21: Warning: for your own safety turn, Switch “off ” and remove plug from power, Quill return spring, Hole location feeding, Quili return spring

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

WARNING: TO AVOID INJURY FROM SPINNING

WORK OR TOOL BREAKAGE, ALWAYS CLAMP

WORKPIECE

AND

BACKUP

MATERIAL

SECURELY

TO TABLE BEFORE OPERATING DRILL PRESS

WITH THE TABLE TILTED.

To return table to original position: loosen the bevel

lock, tilt table back to 0° on bevel scale, and retighten

bevel lock,

HOLE LOCATION

Make a DENT in the workpiece where you want the

hole... using a CENTER PUNCH or a SHARP NAIL.

Before turning the switch ON, bring the drill down to

the workpiece lining it up with the hole location.

FEEDING

Pull down on the feed handles with only enough effort

to allow the drill to cut.

Feeding TOO SLOWLY might cause the drill to burn

. , . Feeding TOO RAPIDLY might stop the motor . . .

cause the belt or drill to SLIP ... tear the workpiece

LOOSE or BREAK the drill bit.

adjustments

WARNING: FOR YOUR OWN SAFETY TURN

SWITCH “OFF ” AND REMOVE PLUG FROM POWER

SOURCE OUTLET BEFORE MAKING ANY ADJUST

MENTS. TO AVOID INJURY FROM THROWN PARTS

DUE TO SPRING RELEASE, FOLLOW INSTRUC

TIONS CAREFULLY AND WEAR EYE GOGGLES.

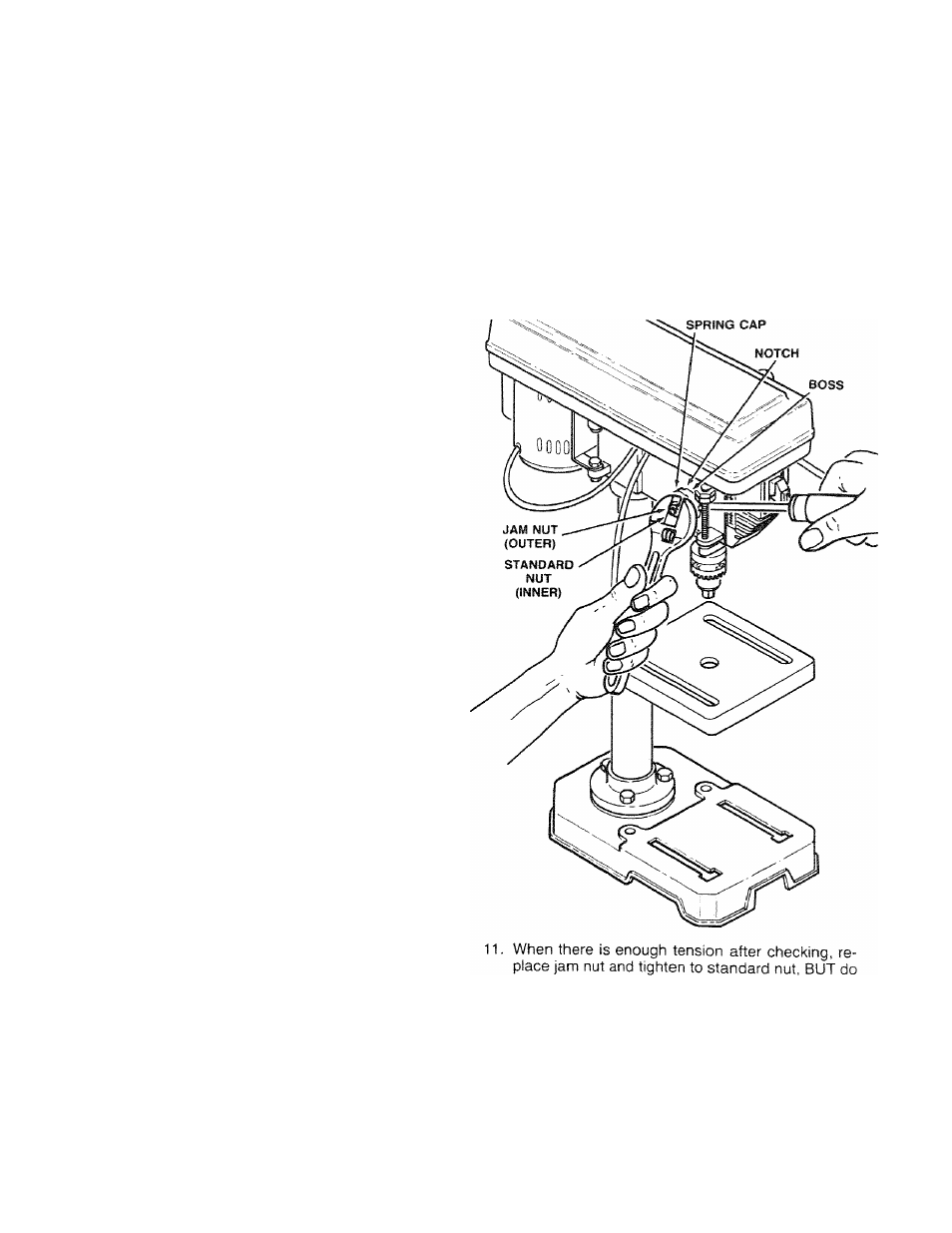

QUILL RETURN SPRING

1. Move the stop nuts down to their lowest position

and lock in place with wrench to prevent quill drop

ping while tensioning spring.

2. Lower table for additional clearance.

3. Work from left side of Drill Press.

4. Place screwdriver in lower front notch of spring

cap, and hold it in place while loosening and remov

ing jam [outer] nut only.

5. With screwdriver remaining in notch, loosen large

standard [inner] nut (approximately 1 /8") until notch

disengages from boss on head. DO NOT REMOVE

THIS NUT.

6. Carefully turn screwdriver counter clockwise and

engage next notch in boss. DO NOT REMOVE

SCREWDRIVER.

7. Tighten standard nut with wrench only enough to

engage boss. Do not overtighten as this will restrict

quill movement.

8. Move stop nuts to upper most position and check

tension while turning feed handles.

9. If there is not enough tension on spring, repeat

steps 4-8 moving only ONE notch each time and

checking tension after EACH repetition.

10. Proper tension is achieved when quill returns gently

to full up position when released from 3/4" depth.

o>

E

12

.

not overtighten against standard nut.

Check quill while feeding to have smooth and un

restricted movement. If movement is too tight,

loosen jam nut and SLIGHTLY loosen standard

nut until unrestricted. Retighten jam nut.

21