Carrier 50BA User Manual

Page 7

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

m

The 064 compressor hold-down bolts must be

removed. The neoprene grommets are installed

between compressor feet and special washers. Hold

down bolts are installed and tightened until there is

a slight pressure on the neoprene grommets.

Compressors have reversible oil pumps that

operate in either direction. Direction of rotation

need not be checked.

NOTE: Do not loosen bolts on 50BA008

compressor.

Water-Cooled Condenser Connections

— Con

densers have water inlet and outlet connections as

shown in Fig. 14. Recirculating systems with low-

temperature water returning to condenser may

require a water regulating valve. Units used on

waste or city water must have a regulating valve on

the inlet of each condenser and will require field

modification for separate condenser piping (except

016). See Fig. 15, 16, 17, 18, 19, 20 and 21 for

typical application and conversions. Connect regu

lating valve capillary to a back-seated liquid service

valve. Arrow on valve body must point in direction

of flow. After connecting capillary, open regulating

valve one turn from back-seated position. Adjust

valve to maintain proper condensing temperature.

Install full size gate valve and strainer in water

supply line. Valve and strainer must be accessible.

Maximum Water Side Working Pressures Are;

50BA008, 012 ................................... ISOpsig

50BA016

.................................... 550 psig

50BA024 thru 054 ................................. 150 psig*

50BA064

.................................... 250 psig

*550

psig

if

factory-installed

couplings

are

removed

and

field-

fabricated manifold is installed.

Condensate Drain

— Requires standard pipe con

nected to condensate pan nipple as shown in Table

4. Pitch downward to open drain. Provide trap

3 in. high and plugged tees for cleaning. If

required, cut hole in panel for drain line. Observe

all local sanitary codes.

Table 4 — Condensate Drain Connections (in.)

Table 5 — Recommended Line Sizes* (in.)

(Condenserless Models)

UNIT SIZE

008,

012

016,

024

028,

034,

044, 054

064

PIPE SIZE

%

1

l'4

T4

Air-Cooled Condenser Connections

— Locate con

denser not more than 60 ft above or 15 ft below

base unit. Install air-cooled condenser in accord

ance with Installation Instructions shipped with

condenser. Consult Carrier System Design Manual

for standard refrigerant piping techniques. Connec

tion location for liquid and hot gas service lines is

shown in Fig. 14. Also see Table 5. Condenserless

units are shipped with a holding charge. After

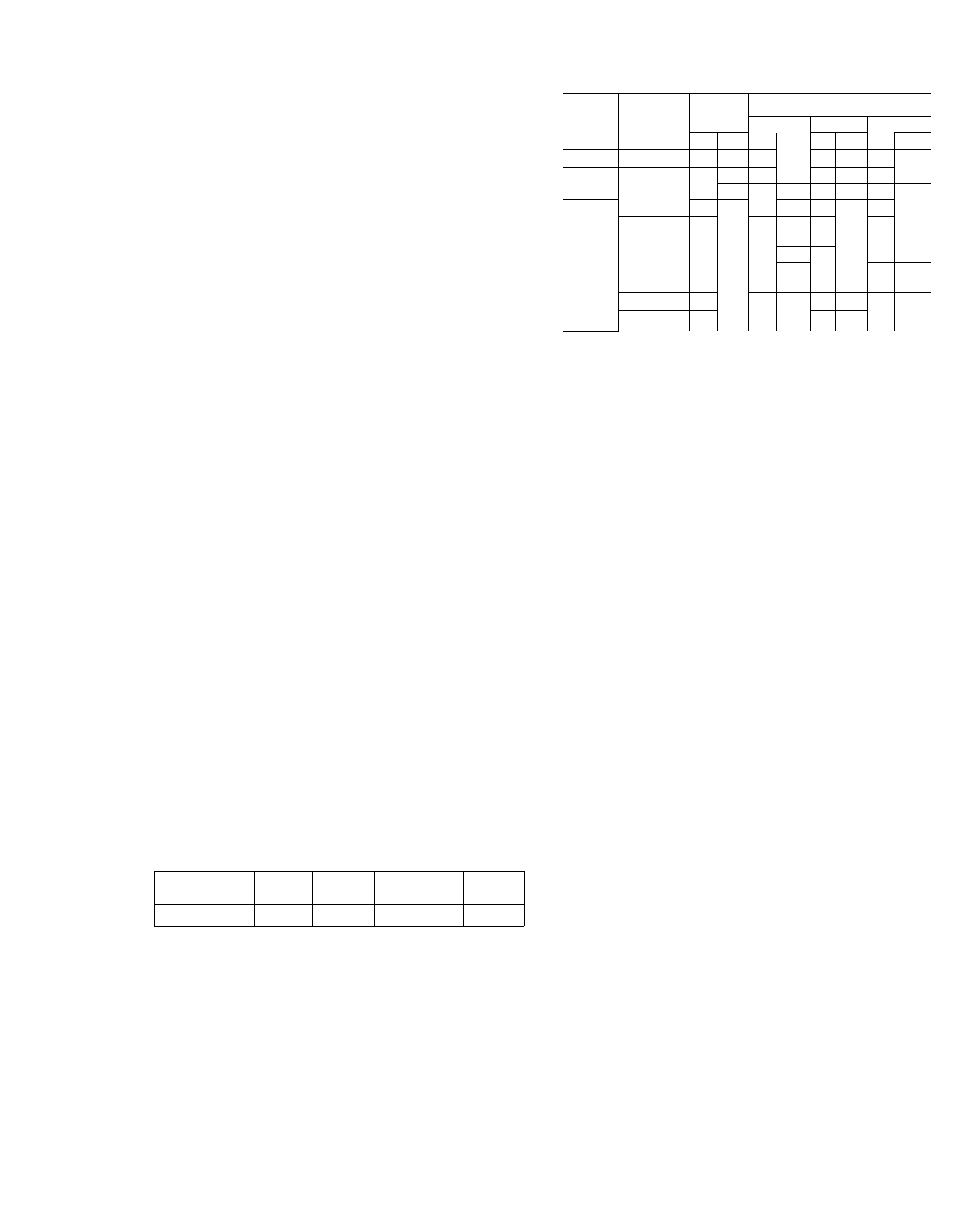

UNIT

50BB

CONN.

LENGTH OF LINE

SYSTEM

SIZESt

20

40

60 -80

L

HG

L

HG

L

HG

L

HG

008

-

’4

Ve

V

2

Ve

‘4

Ve

‘4

Vs

012

-

Vs

Ve

Ve

\

Ve

IVe

Ve

1Ve

016

~

%

IVe

Ve

T/e

V

iVs

Ve

T/s

024

Î & 2 “1

V,

Ve

Ve

Ve

Vs

IVe

Ve nv;

028

1

2

Vs

Vs

ÎVe

V

/8

Ve

V

/8

IVe

Ve

Ve

Ve

T/e

IVs

Vs

V

4

T/e

T/e

034

1 & 2

Vs

'Ve

5/

'9,

tVs

V

4

IVs

4

T/e

044

1 & 2

3

Ve

Ve

iVe

Ve

V

/8

V

/8

IVe

Ve

Ve

Ve

T/e

T/e

V

4

4

T/e

T/e

054

t,2,3

V»

IVe

V

'9,

)Vs

V4

T/e

V

4

iVe

064 ^

1 & 2

Vs

iVe

V/8

IVs^

V4

T/e

4

T/s

HG — Hot Gas Line (OD in )

L — Liquid Line (OD in )

*Using R-22.

1 Sweat connections

refrigerant connections are made, evacuate, leak

test and charge system as described in Charging

Procedure. Refer to Table 1 for unit charge. Water

regulating valve on water-cooled condenser or

condenser airflow on air-cooled condenser must be

properly set before checking system charge.

Carrier Compatible Fittings (50BB008 and 012

units only)

TUBING — Cut tubing to length with tube cutter

and remove burrs.

MECHANICAL CONNECTION - Make one con

nection at a time.

1. Mark required insertion depth on tube, 1-1/4

in. for 5/8- and 3/4-in. OD tubing.

2. Remove plug from fitting and loosen nut one

turn.

3. Position tube, remove plug and insert tube into

fitting. Bottom tube past depth gage mark.

4. Leave nuts at condenser end of tubing. Loosen

and purge one line at a time using holding

charge in base unit.

5. Tighten nuts to stop on unit fitting collar.

6. Open all service valves.

SWEAT CONNECTION

1. Clean tube and remove plug and nut from

fitting.

2. Remove O-ring from inside fitting with bent

pin. Wrap entire valve with wet rag

3. Bottom tube in fitting and solder with low-

temperature solder such as Allstate 430.

Moisture or Liquid Indicators

are located ahead of

thermal expansion valves. They must be full of

liquid refrigerant to indicate proper moisture

content. Operate system 30 minutes before deter

mining moisture content.