Table 3 — torque requirements – Carrier 50BA User Manual

Page 5

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

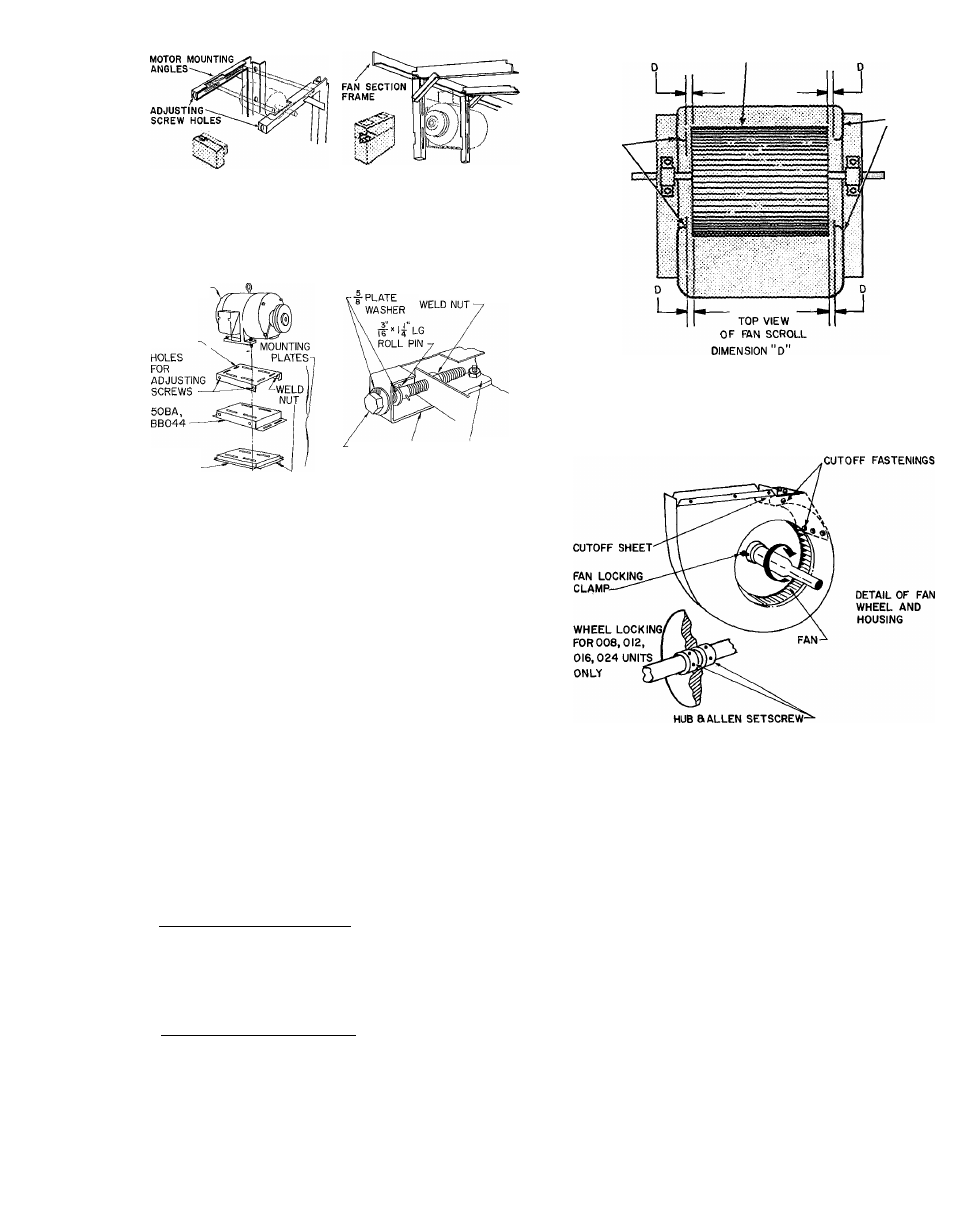

WHEEL

Fig. 5 - 028 and 034

Horizontal Fan Motor

Mounting Angles

Fig. 6 — 054 and 064

Vertical Fan Motor

Mounting Angles

FAN MOTOR

50BA,BB

028,034

SUPPORT CHANNEL

50BA,BB

054,064

-MOTOR

^ MOTOR

Li^oTOR

ADJUSTING

SUPPORT

SUPPORT

SCREW

ANGLE

CHANNEL

Fig. 7 — Motor

Mounting

Fig. 8 — Assembled

Fan Motor

Adjusting Screw

2. Remove two adjusting screws; lift out motor

plate.

3. Position motor on motor plate and fasten with

fasteners provided as shown in Fig. 7.

4. Lift motor-plate assembly and slide onto

channels; be sure plate slides under lip guides.

5. Reinstall adjusting screws and adjust motor

position.

6. Fasten motor plate to channels.

Shaft and Wheel Alignment

— On units where fan

section is shipped separately, check alignments

before mounting fan section.

HORIZONTAL WHEEL CENTERING - All

wheels must be horizontally centered between the

inside edges of their respective fan scroll venturis

(Fig. 9). To adjust individual wheels:

Units 50BA,BB008 thru 024

1. Loosen setscrews holding wheel support to

shaft (Fig. 10).

2. Center wheel by sliding horizontally (Fig. 9).

3. Retighten setscrews.

Units 5QBA,BB028 thru 064

1. Loosen fan wheel locking clamps, one on each

side of fan support (Fig. 10).

2. Center wheel by sliding horizontally (Fig. 10).

3. Re tighten locking clamp bolts using torque

indicated in Table 3.

VENTURI

7SCROLL

MUST BE EQUAL ALL AROUND

Fig. 9 — Horizontal Wheel Centering

Fig. 10 — Fan Locking Detail

- 028,034,044,054,064

Table 3 — Torque Requirements

BOLT SIZE (in.)

5/16

7/16

FAN CLAMP BOLT

RECOMMENDED TORQUE (ft - lb)

15 -

30 ^

35

CONCENTRIC ALIGNMENT - Shaft and wheels

must be concentrically centered with respect to the

venturi or air inlet of the fan housing (Fig. 11).

Units 50BA,BB008 thru 024 - Shaft bearings are

held by a “spider” support, Fig. 12. If shaft and

wheels are concentrically misaligned due to ship

ping shock, it is possible to rebend spider arms to

their original position. Spider should be replaced if

it has been extensively damaged by shipping shock.