Indoor air fan adjustment – Carrier 50BA User Manual

Page 14

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

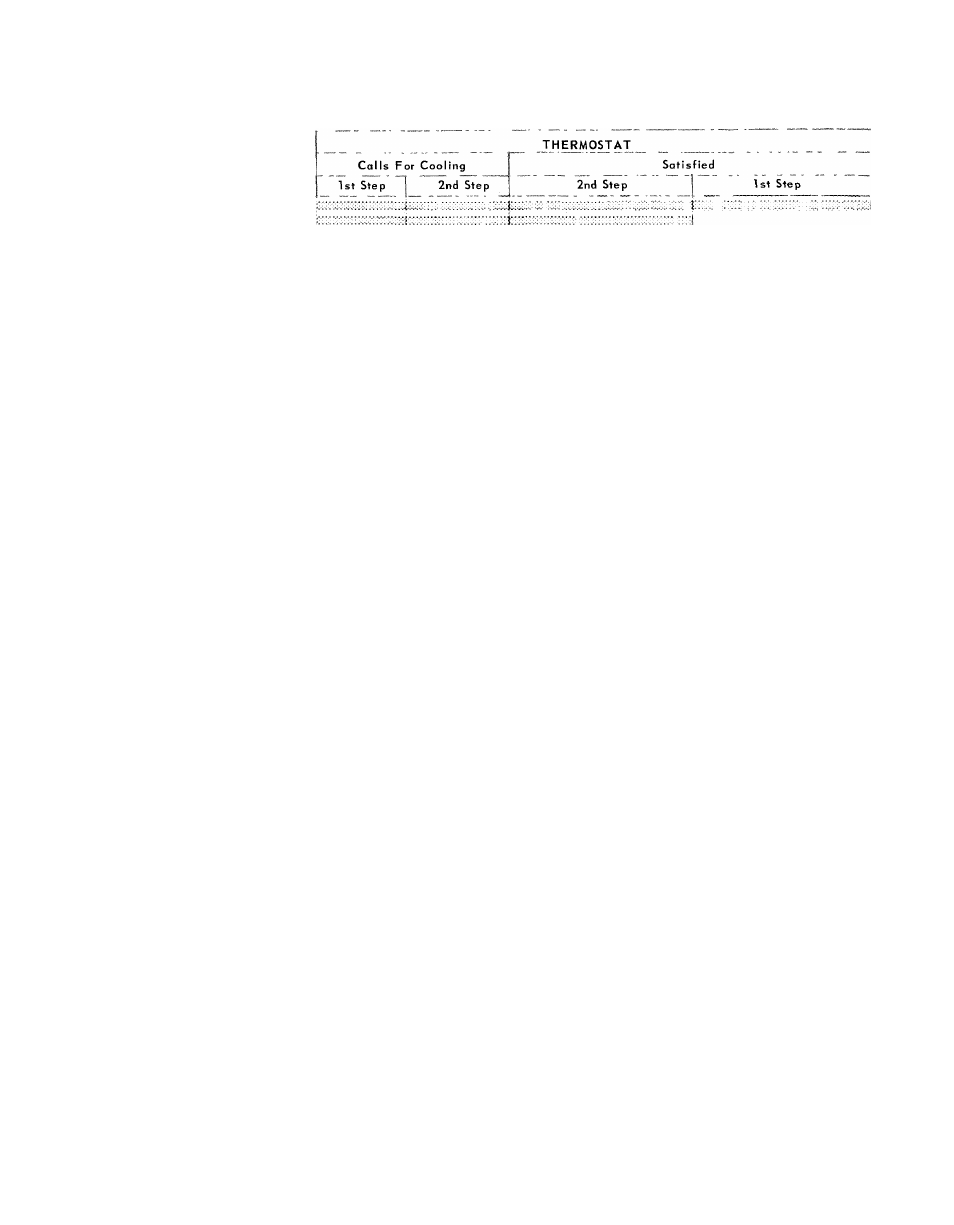

Table 10 — Sequence of Operation with Two-Step Thermostat (016 — 064)

POWER TO CONTROL CIRCUIT AND UNIT SELECTOR SWITCH ON COOL

UNIT

50BA,BB

All

Unit

Sizest

044

&

054

All

Unit

Sizest

024

028

034

044

054

064t

BB064

COMPONENT

Evaporator

Fan

Cooling Tower* *

**

Pump Motor*

15

Crankcase Heater #3*

| 15

Timer Motor #3

Compressor #3

|

Air-Cooled Cond #2* TC-C:.

(#1

on 016)

Crankcase Heater #2*

(#1

on 016)

Timer Motor #2

(#1

on 016)

Compressor #2

(#1

on 016)

Cap Cont Solenoid

(on 064 on ly)

Liquid Line Solenoid

(on 016 on ly)

Air-Cooled Cond #1*

Crankcase Heater #1 *

I’.

Timer Motor #1

Compressor #1

4 min 45

n 40 sec

4 min 45 sec

15

4 min 45 sec

Liq Line Solenoid #2

Pumpout Relay #2

Crankcase Heater #2

Ti mer Motor #2

Compressor #2

Cap. Cont Solenoid

Low Pressure Sw #2

Liq Line Solenoid #1

Pumpout Relay #1

Crankcase Heater #1

Timer

Motor

#1

Compressor

#1

Low Pressure Sw #1

1 5 sec

4 min 45 sec

30 sec

15

4 min 45 sec

30 :

yC:-; Components energized

*When used

tExcept 50BB064

$19 sec (044, 054 only)

**6 min 5 sec (044, 054 only)

NOTES

1

If compressor operation is interrupted by protective devices or a

power failure, timer motor will run 4 min 45 sec (or 6 min 5 sec)

before above cycle can be repeated

2

When

liquid

line

solenoid

(016)

or

capacity

control

solenoid

(064) is energized, it allows refrigerant to flow to complete coil

L

Indoor Air Fan Adjustment

TO CHANGE FAN SPEED (008 thru 034)

1. Shut off unit power supply.

2. Loosen fan belt by loosening fan motor from

mounting bracket. Do not loosen fan motor

mounting bracket from unit.

3. Loosen movable pulley flange setscrew (Fig.

24).

14

4. Screw movable flange toward fixed flange to

increase fan speed and away from fixed flange

to decrease speed using values shown in Table

1. Increasing fan speed increases load on motor.

Do not exceed maximum allowable fan speed

(Table 1) or motor full load amps indicated on

motor nameplate and Table 6.

5. Set movable flange setscrew at nearest flat of

pulley hub and tighten setscrew.