Capacity control valve (fig. 25), Service, Table 8 — factory set point (psig) – Carrier 50BA User Manual

Page 13

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

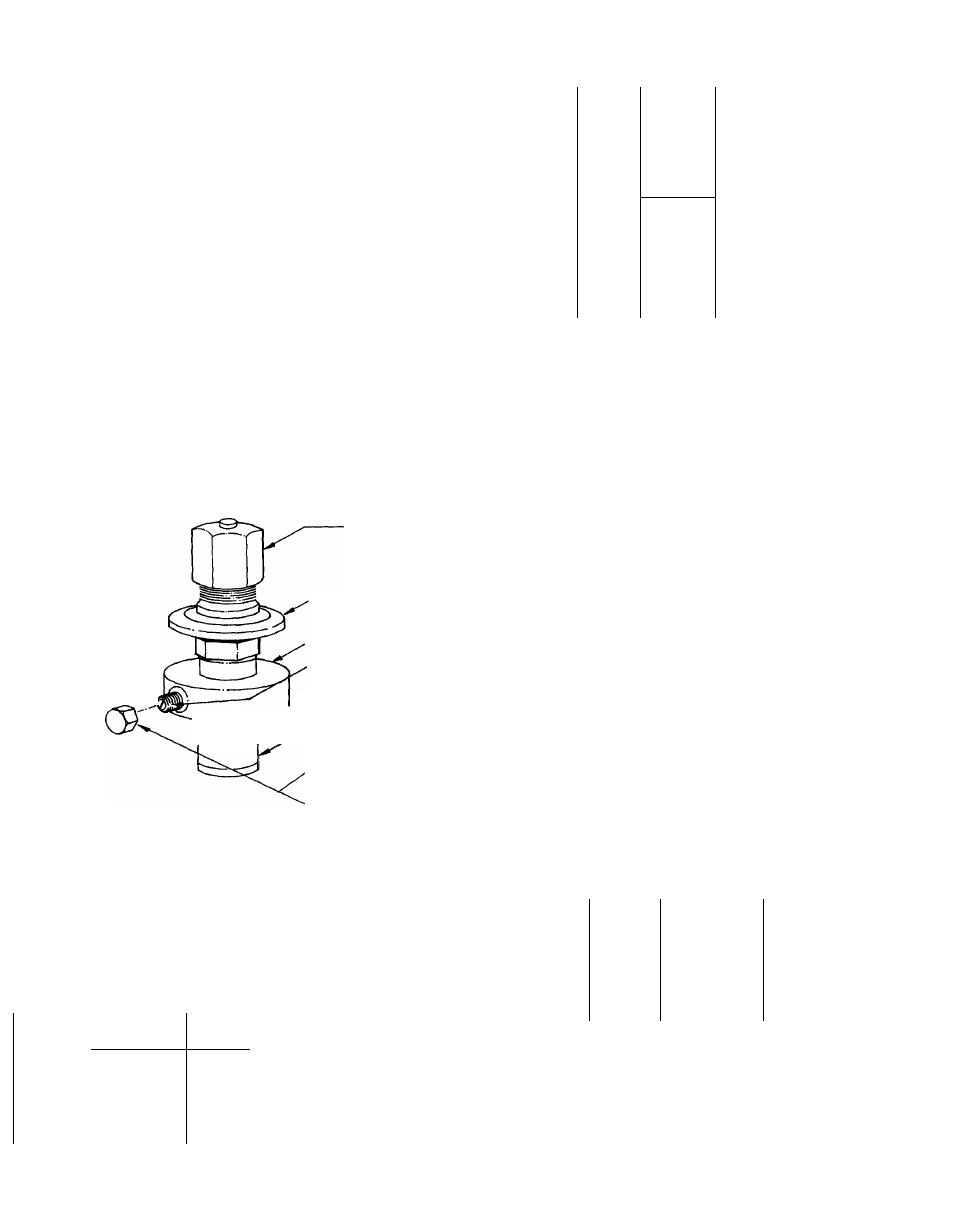

Capacity Control Valve

(Fig. 25)

CONTROL SET POINT (CYLINDER LOAD

POINT) — Adjustable from 0 psig to 85 psig.

Pressure differential between cylinder load-up

point and cylinder unload point is adjustable from

6 psig to 22 psig. (See Table 8)

TO REGULATE CONTROL SET POINT - Turn

adjustment nut clockwise to its bottom stop (with

nut in this position set point is 85 psig). Control

set point is then regulated to desired pressure by

turning adjustment nut counterclockwise. Every

full turn decreases set point by 7.5 psig. (Approxi

mately 11-1/2 turns in counterclockwise direction

will decrease set point to 0 psig.)

PRESSURE DIFFERENTIAL ADJUSTMENT -

Turn differential adjusting screw in counter

clockwise direction to its back-stop position (with

screw in this position, differential is 6 psig).

Pressure differential is set by turning adjustment

screw clockwise. Every full turn increases differ

ential by 1.6 psig. (Approximately 10 turns in

clockwise direction will increase pressure differ

ential to 22 psig.)

CONTROL SET POINT

ADJUSTMENT NUT

POWER HEAD

VALVE BODY

PRESSURE

DIFFERENTIAL

ADJUSTMENT SCREW

BYPASS PISTON RING

BYPASS PISTON

DIFFERENTIAL SCREW

SEALING CAP

REPLACE CAP TO PREVENT

REFRIGERANT LEAKAGE

Table 9 — Two-Step Thermostat Connection

for Capacity Control

COMPONENT

£NERGIZED

Compressor

Liquid line solenoid

Compressor No. 2

Compressor No 1

UNIT

THERMO

TERMINAL

50BA,BB

STEP

CONN.

016

One

T wo

2

3

_

028

034

One

T wo

3

2

044

One

3 and 5

054

T wo

2

One

3 and 6

064

T wo

2

Compressor No 2 and 3

Compressor No 1

Capacity control solenoid

va ive and I iquid ! ine

solenoid valve No. 2*

and compressor No 2

Liquid line solenoid No ]*

and compressor No ]

*BB units only

Fig. 25 — Capacity Control Valve

SERVICE

Pressure Relief Devices (Frangible Disc)

— Installed

on each condenser to 5 OB A water-cooled units at a

setting of 385 ± 5 percent psig (except 064 unit).

The 50BB condenserless units are equipped with a

fusible plug type safety relief in the compressor

with a setting of 197 E or 203 E on all units.

A pressure relief valve with a setting of 385 psig

is used on the 50BA064 condenser. A pressure

relief valve on the compressor is set at 450 psig.

Crankcase Heaters (50BA008, 064, and all 50BB)

— Prevent liquid refrigerant from accumulating in

compressor crankcase during extended shutdown

periods. Resistance heater is automatically ener

gized when compressor stops. If unit has been

disconnected for an extended period, energize

heaters for 12 hours before starting compressor.

The 5 OB A units require heaters if installed in

unheated rooms.

High and Low Pressurestats

— High are located in

electrical panel; low on top of compressor except

50BA008 on suction line; 50BA,BB064, in control

box.

Time Guard® Control Circuit

provides automatic

reset protection (except circuit breaker), time

delay in starting and controlled cycling. If com

pressor shuts down for any reason, control

prevents restarting for time period as follows;

Table 8 — Factory Set Point (psig)

A

UNIT

50BA,BB

ACTION

•

012

Load

Unload

016

Load

Unload

I

064

Load

Unload

UNLOADER

NO. 1

69’“

_ 58_______

69

58

77"''■

58

UNLOADER

NO. 2

74

55

UNIT

50BA,BB

044,054

~M4,028,

034,064

- — — — '—

CIRCUIT

NO.

A

FULL CYCLE

MINUTES

2

1 and 3

5

..........

T'

6.4~

2

5

___ __

В

____ _____

DELAYED START

SECONDS

19'

(5

___

.......... 19"

15

Under normal thermostat cycling, time delay

between compressor starts is shown in B. The 008,

012, and 016 units have a 5-minute cycle with a

15-second delayed start. See Table 10 for 016 thru

064 units sequence of operation. Table is useful in

troubleshooting