Self tapp«« gcsews ccilsbxnati – Carrier 50BA User Manual

Page 4

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

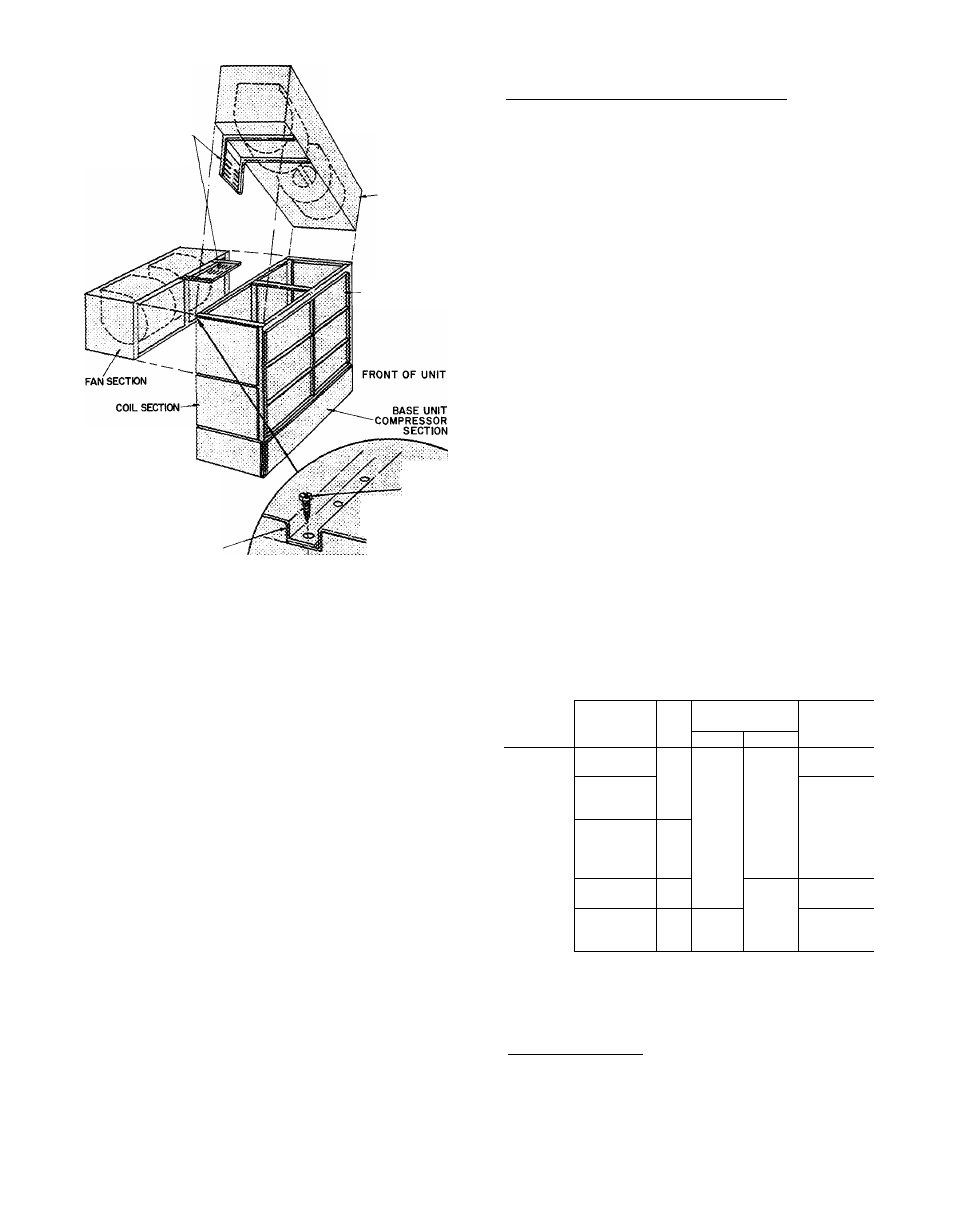

MOTOR MOUNTING

BRACKETS (INSTALL

AFTER MOUNTING

FAN SECTION)

REAR HORIZONTAL FAN

AND VERTICAL FAN

DISCHARGE. 50BA.B8

028,034, D44,054

AND 064

FAN SECTION

FILTER SECTION

NO MOTOR MOUNTING

BRACKET USED WITH

044 SIZE UNIT

THREE FANS ON 054 AND

064 UNITS

REAR PANEL FAN SECTION

self

TAPP««

Gcsews

cciLSBxnati

TOPBSAft

Fig. 4 — Fan Mounting

FAN MOTOR MOUNTING

Units 50BA,BB028, 034, 054 and 064 — Motor,

motor mounting assembly, drive package and

fasteners shipped separate from unit. Install items

after fan section is in place on coil section. See

Tables 1 and 2.

NOTE: Before installing motor or motor

mounts in 028, 034, 054, and 064 units place

plywood over evaporator coil to prevent

damage.

To install motor;

1. Fasten motor mounting angle bracket to fan

section. Use Fig. 3 or 4 as a position reference

and Fig. 5 and 6 as a guide. Be sure lip of angle

brackets are around fan section frame and that

motor mounting plate slots face each other.

2. Position motor on motor plate and fasten with

fasteners provided; use Fig. 7 as a guide.

3. Lift motor-plate assembly and slide into motor

mounting angles as shown in Fig. 5. Plate fits in

angle slots. On vertical mounts, the motor-

frame assembly may be lowered to bottom of

support angle channels.

4. Assemble and install motor adjusting screws as

shown in Fig. 8. Drive roll pins into screws to

prevent screws from backing out while adjust

ing motor position. On 50BA,BB054 and 064

units, the adjusting screws engage the motor

mounting plate.

5. Adjust motor position. Fasten motor mounting

plate to mounting angles.

2 Lift and position fan section on coil section,

Fig. 4.

3. a. Fasten fan section frame to coil section

frame with provided fasteners,

b. Reposition and fasten upper filter frame (on

028 and 034 only).

4. Install (see note regarding 044 size);

a. Motor mounting frame angles.

b. Motor on motor-plate assembly.

c. Motor-plate assembly into frame angles.

d. Other drive package components.

NOTE. Motor mounting plate and channels are

factory installed within fan section on 044 size

units. No angle frame plates or fasteners nec

essary. In this position motor will be on right

side of unit.

5. Adjust:

a. Fan wheel alignment.

b. Shaft alignment.

c. Pulleys

d. Fan belts

6. Replace and fasten:

a. Rear coil section panels, front and rear fan

section panels.

b. All end panels after adjustments.

Table 2 — Alternate Fan Motors and Drives

UNIT

SOBA.BB

NEMA

CENTER LINE

FAN

FRAME

HP

DISTANCE (in.)

SHAFT

SIZE*

Max

Min

DIAM (in.)

008,012

184,56,1451

182T,213

2

3

10.2

10.2

6 8

6.8

V

74

184,56,1451

2

11.8

9 4

016,024

213,182T

3

11 8

8.4

1

184T,215

5

11.8

8 4

1827,213

3

34.4

28 8

028,034

1847,215

254U,213T

5

Th

34.4

33 3

28.8

29.8

F

/16

256U,215T

10

33.3

29 8

044

254U,213T

7/2

14.3

10.1

1

V

256U,215T

10

14.3

10 1

254U,213T

7/2

33.5

29.0

054,064

256U,215T

10

33.5

29.0

284U,254T

15

33.5

29.0

‘Range of motor sizes unit will accept

NOTE:

Motors

and

drives

other

than

those

furnished

with

unit

must be purchased locally

Units 50BA,BB044 — Shipped with motor mount

ing plate installed in fan section. See Tables 1 and

2 for motor data.

To install motor:

1.

Remove bolts holding motor plate to unit

support channels.